Mastering Your DIY Fireplace Surround: A Step-by-Step Guide to a Custom Mantel on a Budget

Embarking on a do-it-yourself (DIY) fireplace surround project can seem daunting, a sentiment I deeply understand. Before I built my first one, the idea felt monumental. Yet, after receiving contractor quotes that ran into hundreds of dollars, I realized I could achieve the same beautiful result for a mere third of the cost by doing it myself. Today, I’m excited to share my detailed, step-by-step method with you, empowering you to create a stunning focal point in your home.

This comprehensive guide will walk you through the entire process of crafting a custom fireplace surround and mantel. You’ll learn essential techniques, from precise measuring and accurate cutting to seamless assembly, ensuring your new fireplace frame fits your living space perfectly. I’ve broken down each stage into simple, clear instructions, making this project accessible and rewarding, even if you’re a newcomer to the world of DIY home improvements.

Get ready to transform your living room, enhance your home’s aesthetic, and gain immense satisfaction from a project completed with your own hands. Let’s build something beautiful together!

How to Thoroughly Plan Your DIY Fireplace Surround Project

Careful planning is the bedrock of any successful DIY project, and building a fireplace surround is no exception. This initial phase is where you lay the groundwork for a smooth, efficient, and error-free construction. I’ve refined my planning process through experience, and now I’m sharing it with you to help you avoid common pitfalls and ensure a perfect outcome.

1. Accurately Measure Your Space

Precision in measurement is paramount; it’s the single most critical step that prevents costly mistakes and ensures a professional finish. I once spent a full hour meticulously measuring, and it saved me from significant rework. Here’s a detailed list of what you need to measure, and remember to measure multiple times for accuracy:

- Height from floor to desired top point: Measure this at three different spots (left, center, right) to account for uneven floors or ceilings.

- Width of the existing fireplace opening: Measure at both the top and bottom of the opening to check for consistency.

- Depth from the wall to the front of your existing fireplace: This determines how deep your new surround needs to be.

- Distance between the fireplace and nearby walls/furniture: Ensure adequate clearance for aesthetics and safety.

- Hearth measurements (if applicable): If you have an existing hearth, measure its length, width, and height to integrate it seamlessly into your new design.

2. Select Your Materials Wisely

The choice of materials impacts both the durability and the aesthetic appeal of your fireplace surround. Based on my experience and testing, certain materials consistently yield the best results for safety and appearance:

- MDF boards for the main frame: Medium-density fiberboard (MDF) is excellent because it’s stable, doesn’t warp easily, and provides a perfectly smooth surface for painting.

- Wood trim pieces for decorative elements: Pine or poplar are good choices for trim due to their workability and affordability.

- Heat-resistant primer and paint: Essential for safety, these coatings can withstand the temperatures around a fireplace, preventing cracking or peeling.

- Basic carpentry tools: A circular saw (or miter saw for precise cuts), level, drill, and screwdriver set are fundamental.

- Safety gear: Always prioritize safety with goggles, a dust mask, and work gloves.

- Measuring and marking tools: A reliable tape measure, a sharp pencil, and a long straight edge are indispensable.

3. Verify Local Building Codes and Regulations

Safety around fireplaces is non-negotiable. Before cutting any material, it is crucial to understand and comply with local building codes. This step can prevent hazards and ensure your project is up to standard. Here’s what I did:

- Contacted the local building office: Inquired about specific codes pertaining to fireplace surrounds and mantels.

- Asked about fire safety requirements: Clarified any regulations regarding material proximity to the firebox.

- Obtained information about needed permits: Some structural changes may require permits.

- Checked minimum clearance distances: Determined how far wood and other combustible materials must be from the firebox opening.

- Inquired about required fire-resistant backing materials: Necessary if your design extends into areas close to heat sources.

- Requested written copies of all requirements: Having documentation ensures clarity and prevents misunderstandings.

4. Establish a Realistic Budget

Financial planning is key to keeping your project on track and avoiding unexpected expenses. My budgeting method ensures all costs are accounted for:

- Itemize every material: List everything, from large MDF sheets to the smallest brad nail.

- Add a 20% contingency: Allocate extra funds for unforeseen mistakes, design changes, or material shortages.

- Compare prices: Check both large hardware stores and local lumber yards for the best deals.

- Include tool costs: Factor in the price of any new tools you might need to purchase or rent.

- Account for permit costs: If permits are required, include their fees in your budget.

- Set aside money for unexpected issues: A buffer for things like incorrect cuts or damaged materials.

- Maintain a record of all receipts: Keep them organized for easy tracking and potential returns.

5. Create Detailed Design Plans and Drawings

A well-thought-out plan on paper can prevent countless problems during construction. I dedicate significant time to detailing my designs:

- Draw the design from the front view: This shows the overall aesthetic and proportions.

- Make side-view drawings: Crucial for understanding depth and how the surround will extend from the wall.

- Mark exact measurements on all drawings: Label every dimension precisely for cutting.

- Note joining points for all pieces: Plan where and how each component will connect.

- List the sequential order of assembly steps: This acts as your construction roadmap.

- Mark spots for any electrical needs: If you plan to add lighting or an electric fireplace insert, plan for power access.

- Draw where trim pieces will go: Visualize all decorative elements before you cut them.

6. Prepare Your Workspace Thoroughly

Before making your first cut, ensure your work area is safe, organized, and ready for construction. A prepared space improves efficiency and reduces hazards:

- Clear the area around the fireplace: Remove furniture, rugs, and anything that could obstruct your work.

- Lay down drop cloths or tarps: Protect your floors from dust, paint, and accidental spills.

- Set up good lighting: Adequate illumination is essential for precision and safety.

- Confirm power outlets are available: Ensure easy access for power tools.

- Create a clean, flat work surface: A stable workbench or saw horses are ideal for cutting and assembly.

- Set up a cutting station: Choose a well-ventilated spot, preferably outdoors or in a garage, to minimize dust indoors.

- Have a first-aid kit readily accessible: Always be prepared for minor injuries.

7. Establish a Realistic Project Timeline

A timeline helps manage expectations and ensures steady progress. Based on my experience with similar projects, here’s a typical breakdown:

- Shopping and material delivery: Allow 1-2 days, accounting for potential delays.

- Basic frame construction: 1-2 full days, depending on complexity.

- Trim work and detailing: 1 full day for precise cuts and attachment.

- Painting and finishing: 1-2 days, including drying time between coats.

- Factor in ample drying time: Especially for glue, filler, caulk, and multiple paint coats.

- Add extra time if you’re new to DIY: It’s better to overestimate than rush the process.

This careful and methodical planning helped me complete my project without major setbacks. I cannot stress enough the importance of taking your time with each planning step – it truly is worth the effort and will contribute significantly to the success and enjoyment of your DIY fireplace surround.

Step-by-Step Process to Build Your Custom DIY Fireplace Surround

Once your planning is complete and your workspace is prepared, it’s time to bring your vision to life. Follow these steps meticulously, and you’ll soon have a stunning custom fireplace surround.

Materials & Tools Required for Construction

Before you begin, ensure you have all the necessary materials and tools gathered. Having everything at hand will streamline the building process.

| Materials | Tools |

|---|---|

| MDF boards (e.g., 1×6 inch, 1×8 inch, depending on design) | Miter saw (for precise angle cuts) |

| 1×2 inch boards (for backing/spacers) | Brad nailer (and compressor if not cordless) |

| 1×4 inch boards (for trim details) | Level (at least 2-foot long) |

| Cove molding (or other decorative trim) | Measuring tape |

| Electric fireplace insert (if desired) | Pencil and straight edge |

| Wood filler (for nail holes and imperfections) | Sanding block or electric sander |

| Caulk (paintable, for sealing seams) | Caulk gun |

| Paint (high-quality, suitable for MDF) | Paint brushes/rollers |

| Primer (specifically for MDF) | Safety glasses |

| Wood glue (strong, quick-drying) | Dust mask |

| Brad nails (various lengths) | Work gloves |

Detailed Step-by-Step Construction Process

1. Remove Existing Mantle (if applicable)

If you have an old fireplace mantel or surround, carefully remove it to prepare a clean slate for your new project. Use a pry bar and hammer, working gently to avoid damaging the wall:

- Use a utility knife to score any caulk lines where the old mantel meets the wall.

- Gently pry off any existing trim pieces, starting from the edges.

- Locate and remove any screws or nails securing the main mantel structure to the wall.

- Once removed, thoroughly clean the wall surface, patching any holes or damage with spackle.

- Using your level and tape measure, mark precise level lines on the wall where the top and sides of your new surround will sit. This serves as your guide for installation.

2. Build the Base Frame of the Surround

The base frame provides the core structure and depth for your fireplace surround. Precision here is vital for stability and a professional look:

- Begin by cutting your primary MDF boards (e.g., 1×6 inch) to the exact height and width specified in your detailed plans. These will form the vertical and horizontal outer frame pieces.

- To add depth and make the surround look more substantial, cut 1×2 inch boards. These will be attached along the back edges of your main frame pieces. This creates a recess that allows the surround to stand proud from the wall.

- Apply a strong wood glue along the edges where the 1×2 boards will meet the larger MDF pieces.

- Securely attach the 1×2 boards using a brad nailer, ensuring the nails are flush with the surface.

- Continuously check for squareness and level as you assemble these components to ensure a straight and true base.

3. Create the Main Structure and Mantle Shelf

This step involves assembling the main body of the surround and the crucial mantel shelf, often the most visible part:

- For the top mantle piece, cut your chosen MDF boards (e.g., 1×6 or 1×8 inch) with precise 45-degree angles at the corners to create clean, mitered joints. This gives a seamless, elegant look.

- Apply wood glue generously to these mitered edges and join them carefully, holding them in place with clamps or painter’s tape while securing with brad nails.

- To maintain consistent gaps and ensure structural integrity, use a 1×2 inch board as a spacer or backing. This helps support the mantel from behind and gives it a sturdy connection point to the wall or the vertical surround pieces.

- Attach the assembled main structure to your wall backing using brad nails. Ensure you hit wall studs where possible for maximum stability. If not hitting studs, use appropriate drywall anchors.

4. Enhance with Trim Details and Decorative Elements

Trim work adds character, definition, and a polished finish to your DIY fireplace surround:

- Install additional 1×6 inch or wider boards around the outer edge of your main frame. These can serve as pilasters or columns, giving your surround a more architectural feel.

- Next, place 1×4 inch boards for the inner trim, framing the actual fireplace opening. This creates a clean visual separation between the fireplace insert and the surround.

- Again, cut beveled edges at 45 degrees for all corner joints on these trim pieces to ensure a seamless, professional appearance.

- For softer, more elegant edges, attach cove molding (or your chosen decorative molding) along the inside or outside corners. Use wood glue and small brad nails, being careful to align the molding perfectly.

5. Perform Essential Finishing Work

This stage is where your project transitions from raw wood to a smooth, paint-ready surface. Patience here pays off immensely:

- Carefully fill all visible nail holes with wood filler. Apply a small amount, pressing it firmly into the hole, and then scrape off any excess.

- Once the wood filler is completely dry (check product instructions), sand all filled areas until they are perfectly smooth and flush with the surrounding surface. Use a fine-grit sandpaper (e.g., 180-220 grit).

- Apply a continuous bead of paintable caulk to all seams and joints where two pieces of wood meet or where the surround meets the wall. Smooth the caulk with a wet finger or a caulking tool for a clean line. This hides any small gaps and creates a professional, sealed look.

- Lightly sand any remaining rough spots or areas that need further refinement.

- Thoroughly clean the entire surface of the fireplace surround. Use a tack cloth or a damp cloth to remove all dust, sanding debris, and fingerprints. A clean surface is crucial for proper primer and paint adhesion.

6. Apply Primer and Paint for a Flawless Finish

The final aesthetic touch comes from a quality paint job. This process requires multiple steps and patience for best results:

- Apply a high-quality primer specifically suitable for MDF. MDF is porous and needs a good primer to seal it and prevent the paint from soaking in unevenly. Allow the primer to dry completely according to the manufacturer’s instructions.

- Once the primer is dry, apply your chosen paint color. Use a high-quality brush for corners and edges, and a small foam roller for flat surfaces to achieve a smooth, even finish with minimal brush strokes.

- Allow the first coat of paint to dry thoroughly.

- Apply a second coat of paint if needed. Most projects benefit from two thin coats rather than one thick one for better durability and coverage.

- Let each coat dry completely between applications to prevent stickiness or uneven drying.

Tips From My Experience for a Flawless DIY Fireplace Surround:

- Always double and triple-check your measurements: This is the single biggest time-saver and error-preventer.

- Make test cuts on scrap pieces first: Especially for mitered angles, this helps you dial in your saw settings before cutting your good material.

- Check for level and square frequently: During assembly and installation, constantly verify that everything is straight and plumb.

- Maintain consistent gaps: When attaching trim pieces, use spacers to ensure even spacing for a symmetrical look.

- Sand lightly between paint coats: A quick pass with a fine-grit sanding block between primer and paint, and between paint coats, will give you an incredibly smooth, professional-grade finish.

An Approximate Cost While Building a DIY Fireplace Surround

One of the most appealing aspects of building your own fireplace surround is the significant cost savings compared to hiring a professional. While prices can vary based on material choices, regional differences, and the complexity of your design, here’s an estimated breakdown based on my experience. Remember to factor in your 20% contingency!

| Item | Estimated Cost | Notes |

|---|---|---|

| MDF Boards | $30–$60 | For the mainframe and inner trim; project size dictates quantity. MDF is cost-effective. |

| 1×2, 1×4 Boards | $10–$25 | Used for added thickness, structural support, and framing. Pine is typically inexpensive. |

| Cove Molding | $10–$20 | Decorative edges, prices vary by style, material (MDF vs. wood), and length needed. |

| Electric Fireplace Insert | $150–$400 | Optional, but a popular addition. Price varies widely based on size, features (heat, flame effects), and brand. |

| Wood Filler and Caulk | $10–$15 | Small containers are usually sufficient for most DIY projects. Essential for a smooth finish. |

| Paint (suitable for MDF) | $15–$30 | High-quality interior paint; matte, satin, or semi-gloss finishes can vary. Opt for durable, washable paint. |

| Primer | $10–$20 | Crucial for MDF to seal the porous surface and ensure even paint absorption. |

| Wood Glue | $5–$10 | A small bottle of strong wood glue should be enough for structural joints. |

| Brad Nails | $5–$10 | Packs of nails for your brad nailer; purchase various lengths for different thicknesses. |

| Molding (optional) | $20–$50 | For adding crown molding, base molding, rope trim, or other intricate decorative elements. Adds custom flair. |

| Hidden Cord Channels | $5–$15 | For managing electrical cords neatly, especially with an electric insert. Improves safety and aesthetics. |

| LED Lighting Strips | $10–$30 | Optional; adds ambient lighting. Cost depends on length, color options, and features. |

| Safety Enhancements | $15–$40 | Includes heat-resistant backing material, fireproof coating sprays, or temperature monitoring supplies if applicable to your installation. |

| Tools (if not owned) | $0–$200+ | Cost can be significant if you need to buy a miter saw, brad nailer, or sander. Consider borrowing or renting tools to save money. |

| Miscellaneous Supplies | $10–$20 | Includes sandpaper, paint brushes/rollers, painter’s tape, safety glasses, and other small consumables. |

| Total Estimated Cost | $300–$975 | This range largely depends on the quality of materials chosen, whether you own the necessary tools, and the extent of additional customization. You can often achieve a stunning result for well under $500. |

Essential Safety Considerations for Your Fireplace Surround Project

Safety must always be your top priority when working on any home improvement project, especially one involving a fireplace. Neglecting safety can lead to serious injury or fire hazards. Here are critical safety considerations to keep in mind throughout your DIY fireplace surround build:

During Construction:

- Personal Protective Equipment (PPE): Always wear safety glasses or goggles to protect your eyes from flying debris, especially when cutting or nailing. A dust mask is crucial when cutting MDF or sanding, as wood dust can be a respiratory irritant. Wear work gloves to protect your hands from splinters and sharp edges.

- Tool Safety: Familiarize yourself with all power tools before use. Ensure blades are sharp and guards are in place. Always unplug tools when changing blades or performing maintenance. Keep your work area clear to prevent tripping hazards. Never force a tool; let it do the work.

- Electrical Safety: If integrating an electric fireplace insert or lighting, ensure all wiring is done correctly and adheres to electrical codes. If you’re unsure, consult a qualified electrician. Avoid overloading circuits.

- Ventilation: When cutting wood, painting, or using adhesives, ensure your workspace is well-ventilated to minimize exposure to fumes and dust.

- Fire Extinguisher: Keep a functional fire extinguisher readily accessible in your workspace, especially when working with power tools or in close proximity to the fireplace.

Fireplace-Specific Safety (Post-Construction):

- Clearance to Combustibles: This is perhaps the most critical safety aspect. Local building codes dictate minimum clearance distances for combustible materials (like wood, MDF) from the firebox opening. Ensure your design adheres to these strict guidelines to prevent heat transfer and potential fires.

- Heat-Resistant Materials: If your surround design brings materials closer than recommended clearances, you must use fire-resistant backing materials (e.g., cement board, fire-rated drywall) behind the wood. Consider heat-resistant paints or coatings for surfaces directly exposed to heat.

- Ventilation for Heat: If you have a functional wood-burning or gas fireplace, ensure your new surround does not obstruct any essential vents or grates designed for heat dissipation. Proper airflow is vital for safe operation.

- Stability and Mounting: Ensure your fireplace surround is securely anchored to the wall, especially if it’s large or heavy. A wobbly mantel can be a hazard, particularly if decorative items are placed on it. Use appropriate fasteners for your wall type (studs, drywall anchors).

- Electric Fireplace Considerations: If using an electric insert, ensure it has proper ventilation and is not enclosed in a way that traps heat. Follow the manufacturer’s installation guidelines precisely. Route electrical cords safely, ideally through hidden cord channels, to prevent tripping or overheating.

- Regular Inspection: After construction, regularly inspect your surround for any signs of heat damage, cracking, or loosening of components, especially after using the fireplace. Address any issues immediately.

By following these safety guidelines, you can ensure your DIY fireplace surround is not only beautiful but also a safe and lasting addition to your home.

How Do I Maintain and Clean My New Fireplace Surround?

A well-maintained fireplace surround will continue to be a beautiful focal point for years. Based on my experience, a consistent cleaning and maintenance routine is simple to implement and makes a big difference in preserving its look and longevity.

Regular Cleaning Habits

- Dust Weekly: Use a soft, dry microfiber cloth to gently dust all surfaces of the surround. This prevents dust buildup from becoming embedded.

- Gentle Cleaning Monthly: For painted surfaces, use a small amount of mild, wood-safe cleaner (or a damp cloth with a tiny bit of dish soap) on a soft cloth. Avoid abrasive cleaners that can damage the finish.

- Address Marks Promptly: Spills, scuffs, or marks should be cleaned as soon as you spot them to prevent staining or setting in.

- Clean Insert Screen: If you have an electric fireplace insert, wipe its screen with a damp, lint-free cloth to keep it clear and dust-free.

- Keep Air Vents Dust-Free: For any functional fireplace, ensure that air vents on the surround (if applicable) are free from dust or obstructions to maintain proper airflow.

Seasonal Care and Proactive Checks

1. Every Three Months (or Seasonally):

- Check All Joints for Tightness: Periodically inspect all mitered corners and structural joints to ensure they remain tight and secure.

- Look for Signs of Heat Damage: Especially if your fireplace is regularly used, check for any discoloration, warping, or cracking that might indicate excessive heat exposure.

- Clean Built-Up Dust in Corners: Use a soft brush attachment on a vacuum cleaner to remove dust that accumulates in crevices and decorative moldings.

- Test Stability of the Mantel: Gently push on the mantel shelf to ensure it feels secure and doesn’t wobble.

- Wipe Down All Surfaces Thoroughly: Give the entire surround a more thorough cleaning with your gentle cleaner to remove any accumulated grime.

2. Fixing Small Issues Promptly:

- Fill Tiny Cracks with Wood Filler: Small hairline cracks can appear over time. Fill them with a tiny bit of wood filler, sand smooth, and touch up with paint.

- Touch-Up Paint Marks: Keep a small amount of your original paint for quick touch-ups of chips or scuffs.

- Tighten Loose Trim Pieces: If any decorative trim feels loose, re-secure it with a small amount of wood glue and brad nails if necessary.

- Repair Loose Caulk Lines: Over time, caulk can shrink or detach. Reapply fresh caulk to maintain a seamless look.

- Clean Stubborn Stains: For more persistent stains, try a magic eraser or a very dilute solution of rubbing alcohol on a hidden spot first.

3. When to Consider Professional Help:

- Large Cracks Appear: Extensive cracking across the main structure might indicate a more significant issue or improper installation.

- Paint Starts Peeling Extensively: This could be a sign of inadequate surface prep or an underlying moisture problem.

- Structure Feels Loose or Unstable: If the entire surround feels wobbly, it might require reinforcement.

- Significant Heat Damage Shows: Obvious charring, warping, or severe discoloration near the firebox should prompt immediate investigation.

- Water Marks or Swelling Form: Indicates a leak or moisture issue that needs to be addressed structurally.

Quick Maintenance Tips for Your DIY Fireplace Surround:

- Avoid harsh chemical cleaners: They can strip paint or damage finishes.

- Keep water use minimal: Damp cloths are fine, but excessive water can warp wood or damage paint.

- Always test new cleaners on hidden spots: Before applying to visible areas, ensure they don’t cause discoloration.

- Clean spills right away: Quick action prevents stains from setting.

- Check seals around the fireplace insert regularly: Ensure they are intact for efficiency and safety.

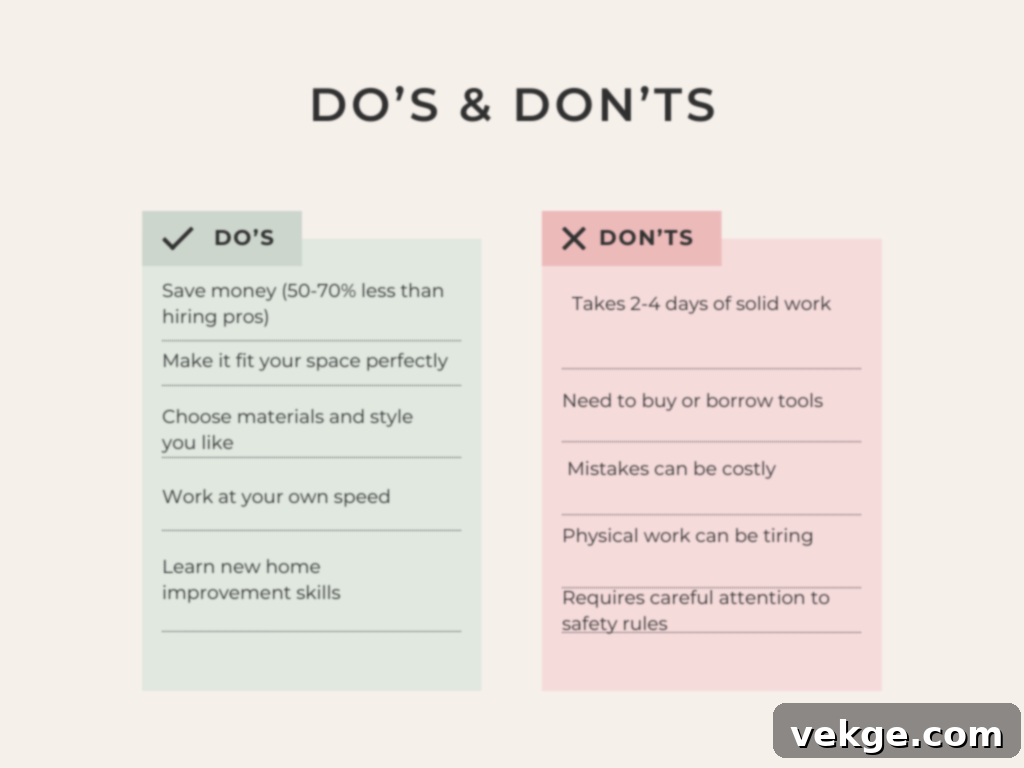

What Are the Pros & Cons of Building Your Own Fireplace Surround?

Deciding whether to tackle a DIY fireplace surround project involves weighing the benefits against the potential challenges. Understanding both the pros and cons can help you determine if this project is right for you.

Pros of Building a DIY Fireplace Surround:

- Significant Cost Savings: This is often the primary motivator. Building it yourself can save you hundreds, even thousands, of dollars compared to hiring a professional carpenter or contractor. You primarily pay for materials, not labor.

- Complete Customization: You have absolute control over the design, dimensions, materials, color, and trim details. This allows you to create a unique piece that perfectly matches your home’s aesthetic and your personal style, something off-the-shelf options rarely offer.

- Sense of Accomplishment: There’s immense satisfaction and pride in completing a large-scale home improvement project with your own hands. It adds a personal touch and a story to your home.

- Skill Development: It’s a fantastic opportunity to learn new carpentry, measuring, cutting, and finishing skills that can be applied to future DIY projects around your home.

- Quality Control: You get to choose the quality of materials and ensure the craftsmanship meets your standards, without having to rely on a third party.

- Flexible Timeline: You can work at your own pace, fitting the project into your schedule without the pressure of contractor deadlines.

Cons of Building a DIY Fireplace Surround:

- Time Commitment: This is not a quick project. From planning and material sourcing to construction and finishing, it requires a significant investment of your time, potentially several weekends.

- Skill Requirements: While this guide simplifies the process, it still requires basic carpentry skills, precision in measuring and cutting, and patience with finishing. Mistakes can be costly in terms of materials and time.

- Tool Investment: If you don’t already own essential tools like a miter saw, brad nailer, and sander, the initial investment in tools can add to the overall cost. (Though these tools can be used for future projects).

- Potential for Mistakes: Without professional experience, there’s a higher chance of miscuts, uneven joints, or less-than-perfect finishes, which can lead to frustration and additional material costs.

- Safety Risks: Working with power tools and around a fireplace (even if non-functional) carries inherent safety risks if proper precautions aren’t followed. Understanding and adhering to building codes is also crucial.

- Physical Demands: The project involves lifting, cutting, kneeling, and sanding, which can be physically demanding.

- No Professional Guarantee: Unlike a contractor’s work, there’s no professional warranty on your DIY build. Any issues that arise will be your responsibility to fix.

Ultimately, the decision to build your own fireplace surround depends on your comfort level with DIY projects, your available time, budget, and desire for customization. For many, the rewards far outweigh the challenges.

Amazing Customization and Enhancement Tips for Your Fireplace Surround

Building your own fireplace surround opens up a world of customization possibilities, allowing you to truly tailor it to your home and personal taste. Don’t be afraid to think creatively and add unique touches that reflect your style. Here are some fantastic ideas to elevate your custom build:

| Category | Customization Tips |

|---|---|

| Paint Techniques | – Try a matte finish for a contemporary, soft, and elegant look that hides imperfections. – Use satin or semi-gloss paint for easy cleaning and a subtle sheen that adds durability. – Apply two thin, even coats of paint instead of one thick layer for a smoother, more professional finish. – Sand lightly between coats (after primer and between paint coats) to eliminate dust nibs and achieve a glass-like surface. – Pick colors that perfectly match or complement your room’s existing trim, wall color, or decorative accents. |

| Molding Options | – Incorporate simple crown molding at the very top for a classic, finished transition to the wall/ceiling. – Add beadboard or shiplap panels inside the vertical frame sections for a rustic or coastal farmhouse vibe. – Opt for flat panel trim for clean, modern lines and a minimalist aesthetic. – Use rope molding or dental molding for subtle, intricate detail that adds a touch of traditional elegance. – Choose base molding that matches or complements your room’s existing baseboards for a cohesive look. |

| Practical Add-ons | – Design hidden cord management channels within the frame to conceal wires for electric inserts, TVs, or lighting, ensuring a clean and safe setup. – Integrate built-in LED lighting strips under the mantel or within decorative niches for ambient lighting that highlights decor. – Create extra shelf depth on the mantel for displaying larger decor items, books, or art pieces. – Implement removable panels for easy access to electrical components or the fireplace insert for maintenance. – Use corner blocks or robust joining plates internally for stronger, more durable structural joints. |

| Size Adjustments | – Extend side panels for tall ceilings to create a grand, imposing presence and draw the eye upwards. – Make the surround narrower or shallower for small rooms to avoid overwhelming the space and maintain flow. – Add width to fill large wall spaces, creating a prominent and balanced focal point in bigger living areas. – Build shallow depth for tight spots or hallways where a bulky mantel would impede movement. – Scale trim size and detail to the overall room size to ensure aesthetic harmony. |

| Storage Solutions | – Incorporate hidden drawers or pull-out compartments directly below the mantel for discreet storage of remotes, matches, or small essentials. – Build side cabinets or open shelving on either side of the fireplace for displaying decor or housing media equipment. – Design pull-out tool storage for fireplace tools (if functional) to keep them organized and out of sight when not in use. – Create the look of built-in wood storage cubbies without the actual function, perfect for purely decorative displays. – Add a simple remote control pocket on the side or underneath the mantel for easy access and clutter prevention. |

| Material Mix Ideas | – Combine painted MDF for the main structure with real stained wood trim for a sophisticated contrast. – Create a painted base surround with a contrasting stained wood mantel top for a two-tone effect. – Apply stone veneer accents or a thin layer of brick veneer to the inner frame for a rustic or industrial touch. – Integrate small tile inlay details or mosaic patterns around the firebox opening for a custom artistic flair. – Add slim metal accent strips (e.g., brushed brass, matte black) along edges for a modern, architectural look. |

| Seasonal Flexibility | – Install small hooks or picture hangers on the inside or top of the mantel for easy seasonal decor changes. – Embed magnetic attachment points for quickly changing decorative elements or festive garlands. – Design removable panel sections that can be swapped out for seasonal themes or different looks. – Include adjustable shelving within any side cabinets to accommodate varying sizes of decor items. – Create changeable insert frames for photos or seasonal artwork within the surround itself. |

| Safety Enhancements | – Always use a heat-resistant backing material (like cement board) behind any wood that is too close to a functional firebox. – Ensure proper ventilation gaps for any heat-producing fireplace, preventing heat buildup and ensuring safe operation. – Implement a robust cable management system for all electrical components to prevent hazards. – Apply fireproof coating or spray to any vulnerable wooden surfaces near high heat zones. – Plan for temperature monitoring spots if you’re concerned about heat transfer, or for smart home integration. |

| Cost-Saving Options | – Mix high-end and low-end materials strategically; use expensive trim sparingly on an MDF base. – Utilize MDF predominantly for all painted sections, as it’s significantly cheaper than solid wood. – Build the project in phases, allowing you to spread out costs over time. – Shop local surplus stores, reclamation yards, or online marketplaces for discounted materials or unique trim pieces. – Create full-scale templates from cardboard or cheap plywood before cutting your final materials to avoid costly mistakes. |

Conclusion: Your Stunning Custom Fireplace Awaits

By taking on this DIY fireplace surround project, you’re not just building a piece of furniture; you’re crafting a centerpiece for your home, infusing it with personal style and undeniable charm. My own experience taught me that I saved over $500 by making mine instead of hiring someone, and I’m confident you can achieve similar savings while enjoying the process.

Your new fireplace surround will not only add significant style and value to your room but also give you an immense sense of pride and accomplishment every time you look at it. Remember to approach each step with patience and precision. Take your time with measurements, diligently follow all safety rules, and never rush the process, especially during cutting and finishing. Crucially, always remember to check local building codes before you begin, and keep your fire extinguisher handy throughout the build and beyond.

If you’re ready to transform your living space, gather all your materials, dedicate a focused weekend or two, and embark on this rewarding home improvement journey. The satisfaction of a beautiful, custom-built fireplace mantel, crafted by your own hands, is truly unparalleled. Looking for more inspiration? Explore my other DIY guides on built-in shelving and custom trim work to continue enhancing your home!