Floor Trusses vs. Floor Joists: The Ultimate Guide to Choosing the Best Floor System for Your Home

Embarking on a new home build or a significant renovation project brings a myriad of crucial decisions, none more fundamental than selecting the right structural components for your floors. The choice between floor trusses and traditional floor joists is a foundational one that can profoundly impact your project’s timeline, budget, design flexibility, and long-term performance.

While both floor trusses and floor joists are engineered to provide essential support for your flooring, they achieve this through distinct designs and installation methods, leading to vastly different outcomes. Many homeowners and even some builders are not fully aware of these critical distinctions. This comprehensive guide will meticulously break down what each option entails, exploring their unique advantages, potential drawbacks, cost implications, and detailed installation processes. By the end of this article, you will possess the clarity and knowledge necessary to confidently select the floor system that perfectly aligns with your project’s specific requirements and your vision for a durable, functional, and aesthetically pleasing living space.

Understanding Floor Systems: Trusses vs. Joists

The floor system forms an indispensable part of any structure’s foundation, providing stability and support for everything above. Choosing the correct system is paramount for the structural integrity and longevity of your building. Let’s delve into the specifics of these two primary options and understand how they function.

What are Floor Trusses?

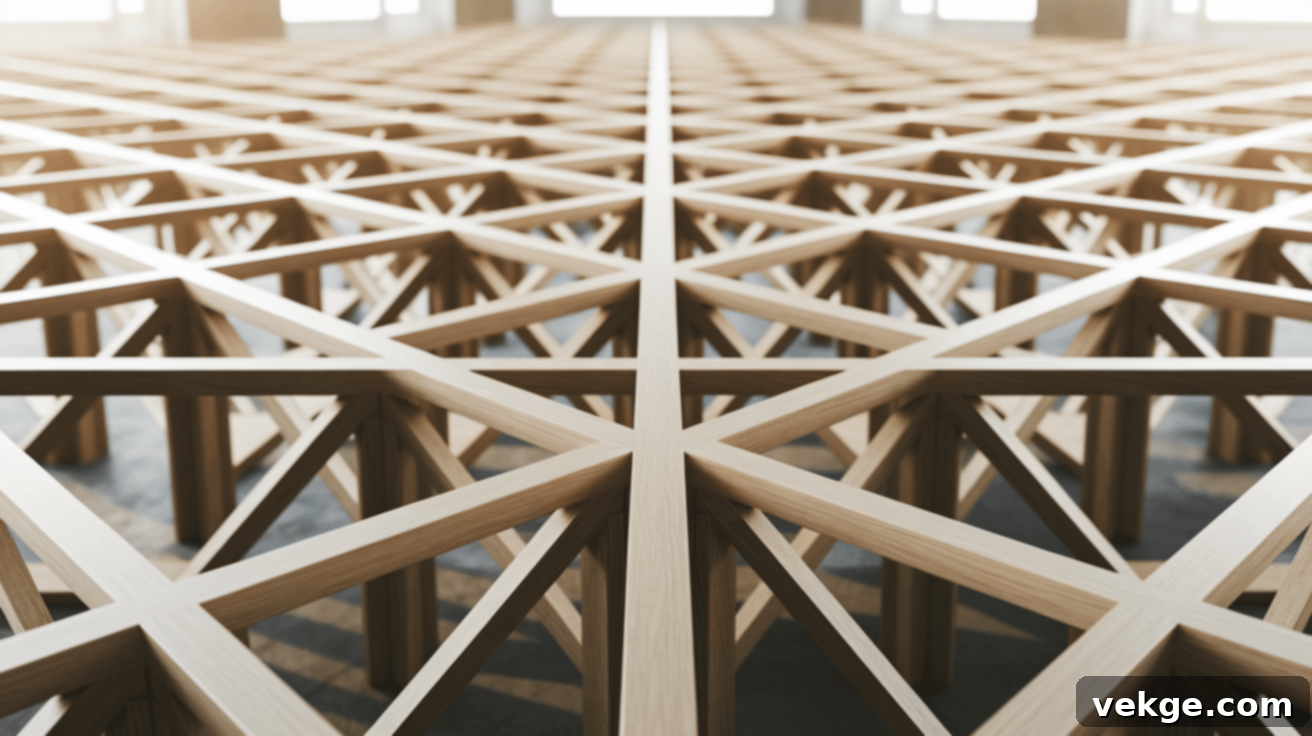

Floor trusses are sophisticated, engineered components primarily constructed from wood, though metal variants exist. Their defining characteristic is a triangular, open-web design, which resembles a series of connected triangles. These prefabricated structures consist of parallel top and bottom chords, connected by diagonal or vertical web members. This intricate design creates a robust, lightweight framework that efficiently distributes weight across greater spans.

One of the most significant advantages of floor trusses is their ability to span much longer distances without requiring intermediate support walls or beams. This makes them an exceptional choice for creating expansive, open-concept living spaces, large garages, or commercial buildings where unobstructed areas are desired. Furthermore, the open web configuration between the chords provides generous, clear pathways for routing plumbing, electrical wiring, and HVAC ductwork, simplifying utility installation and potentially reducing labor costs during construction. Trusses are typically custom-manufactured off-site to precise specifications, ensuring high quality control and consistency.

What are Floor Joists?

Floor joists represent the traditional and time-tested method of floor support. These are essentially straight, solid wood beams (typically lumber such as Douglas fir, Southern pine, or engineered wood products like I-joists) that run horizontally, parallel to each other, and are spaced at regular intervals. They serve to directly support the subfloor above and transfer the applied loads to the foundational walls, columns, or larger support beams beneath.

Floor joists have been a staple in residential construction for centuries due to their straightforward design, readily available materials, and relatively simple installation process. They are particularly common in standard home designs with typical room sizes and less demanding span requirements. While robust and reliable for their intended applications, traditional solid wood joists offer limited flexibility for complex utility routing, often requiring drilling or notching (which can compromise structural integrity if not done correctly) to accommodate pipes and wires. Despite these limitations, their cost-effectiveness and familiar installation methods continue to make them a popular choice for many builders and homeowners focused on conventional construction.

Key Differences: Floor Trusses vs. Floor Joists

Understanding the fundamental differences between floor trusses and floor joists is paramount before making a decision. Each system offers distinct advantages and presents specific considerations that will influence your project’s design, functionality, and budget. The table below provides a quick overview of their primary contrasting features.

| Feature | Floor Trusses | Floor Joists |

|---|---|---|

| Span and Load Capacity | Can cover larger distances without extra support, ideal for heavy loads. | Requires more support for larger spans, suitable for typical residential loads. |

| Utility Integration | Easier integration of plumbing, electrical, and HVAC through open webs. | Limited space for utilities, often requires drilling or notching. |

| Design Flexibility | Ideal for complex designs like vaulted ceilings, custom shapes, and open floor plans. | Best for standard, simple designs and traditional layouts. |

| Cost | Higher initial cost due to engineering and prefabrication. | More affordable upfront material and labor costs. |

| Ease of Installation | More complex to position (often requires crane), but faster once placed. | Easier and quicker manual installation, piece by piece. |

| Sound Insulation | Open web design can sometimes transmit sound more readily if not properly addressed. | Solid mass offers slightly better inherent sound dampening between floors. |

| Dimensional Stability | Less prone to warping, twisting, or shrinking due to engineered design. | More susceptible to natural wood characteristics like warping, shrinking, or squeaking over time. |

Span and Load Capacity

When considering the structural requirements of your project, span and load capacity are critical. Floor trusses truly excel in this area. Their engineered design allows them to bridge significantly wider expanses without the need for additional support beams or load-bearing walls. This capability is invaluable for creating expansive, column-free spaces such as large living rooms, open-plan kitchens, or commercial areas where architectural freedom is paramount. Trusses are also inherently strong and can handle heavier loads more effectively, making them suitable for areas with heavy fixtures, large appliances, or high foot traffic.

Conversely, floor joists are best suited for shorter distances and typical residential loads. While perfectly adequate for standard room sizes in most homes, they will require more frequent supports (such as bearing walls or girders) as spans increase. For very long spans, solid joists would need to be prohibitively deep or closely spaced, becoming less cost-effective and practical. Understanding your desired room dimensions and the expected weight the floor will bear is crucial for this consideration.

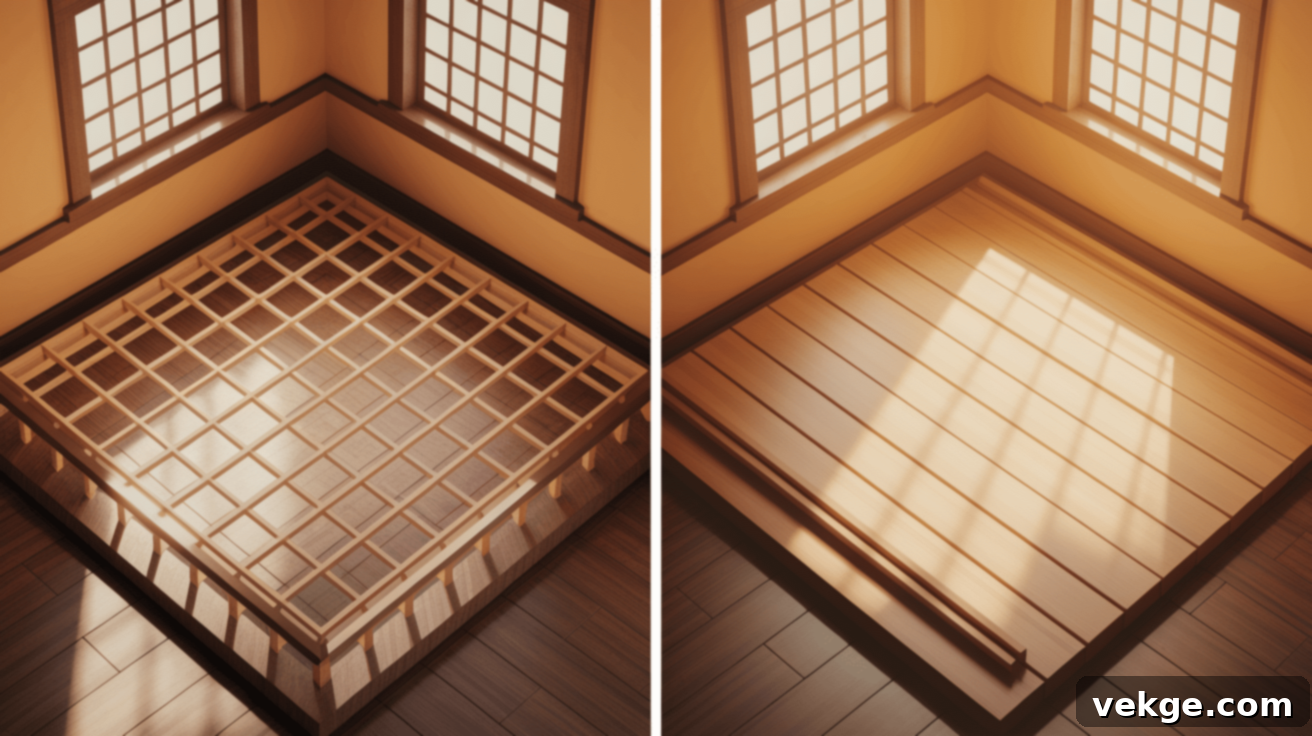

Utility Integration and HVAC

One of the most compelling benefits of floor trusses, particularly in modern construction, is their superior utility integration. The open-web configuration provides clear, unobstructed channels for the seamless routing of plumbing pipes, electrical conduit, and large HVAC ductwork. This eliminates the need for cutting, drilling, or notching structural members, which not only saves significant labor time and cost but also preserves the structural integrity of the floor system. Builders can easily run utilities through these open spaces, leading to more efficient installation, fewer conflicts between trades, and simpler access for future maintenance or upgrades.

In contrast, floor joists present limitations when it comes to accommodating utilities. Running pipes and ducts often requires drilling holes through the joists or creating notches along their edges. These modifications must be carefully planned and executed to avoid compromising the joist’s strength, adhering strictly to building codes. Large ductwork, in particular, can be challenging to integrate, sometimes necessitating bulkheads or dropped ceilings, which can impact ceiling height and design aesthetics. This often results in more complex and time-consuming utility installations compared to the ease offered by open-web trusses.

Design Flexibility and Architectural Freedom

For projects demanding unique architectural features or unconventional layouts, floor trusses offer unparalleled design flexibility. They can be custom-engineered to accommodate various shapes, slopes, and load points, making them ideal for complex roof lines, vaulted ceilings, or unusual floor plans. Architects and designers appreciate the freedom trusses provide to create vast, open spaces without the visual obstruction of columns or excessive load-bearing walls. This adaptability allows for more innovative and aesthetically pleasing designs that might be difficult or impossible to achieve with traditional joists.

Floor joists, while robust, are better suited for simpler, more traditional designs. Their linear nature makes them excellent for conventional rectangular rooms and straightforward building layouts where design complexity is not a primary concern. While they can certainly support a beautiful home, they offer less inherent flexibility for highly customized structural elements or very large, open-concept spaces without significant additional structural support.

Cost Implications and Budgeting

The financial aspect is often a primary driver in decision-making. Floor joists generally boast a lower initial material and labor cost. Solid lumber is often less expensive per linear foot than engineered trusses, and their straightforward installation requires less specialized equipment and fewer skilled trades, translating to quicker manual setup. This makes joists an attractive option for projects with tighter upfront budgets or for standard homes where basic functionality is the priority.

However, while floor trusses have a higher initial cost due to their custom engineering, manufacturing, and transportation, they can offer significant long-term savings. The ease of utility installation reduces labor hours for plumbers, electricians, and HVAC technicians. Their superior span capability can reduce the need for interior bearing walls, saving on foundation and framing costs. Furthermore, their dimensional stability often means fewer issues with squeaks, sagging, or warping over the building’s lifespan, leading to lower maintenance and repair expenses down the road. When considering costs, it’s essential to look beyond the initial purchase and evaluate the total cost of ownership over the life of the structure.

Installation Process and Timeline

The installation process for each system differs considerably, impacting the overall construction timeline. Floor trusses are prefabricated off-site, arriving at the construction site ready for installation. While their larger size may require specialized equipment like cranes for lifting and positioning, their installation on-site can be remarkably fast once they are in place. Fewer individual pieces mean quicker framing of the floor system.

In contrast, floor joists are typically cut to size on-site from raw lumber. This involves more manual labor for measuring, cutting, and securing each individual joist, which can be more time-consuming. However, it requires less specialized equipment, making it feasible for smaller crews. The complexity and duration of installation will depend heavily on the project’s size and the experience of the framing crew.

Sound Transmission and Insulation

The characteristics of each floor system also play a role in sound transmission between floors. The open-web design of floor trusses, while excellent for utilities, can sometimes allow sound to travel more freely through the open spaces. This means that builders may need to incorporate additional soundproofing measures, such as insulation batts or resilient channels, to achieve desired acoustic performance, especially in multi-story homes or apartments.

Floor joists, being solid members, inherently offer a slight advantage in terms of sound dampening simply due to their mass. While they are by no means soundproof, the solid wood can help attenuate sound transfer more effectively than an open cavity. However, effective sound insulation in any floor system typically requires a combination of good design, proper subfloor materials, and strategically placed insulation.

Detailed Cost Analysis: Trusses vs. Joists

A comprehensive understanding of the financial implications is critical for any construction project. Both floor trusses and floor joists present different cost structures, affecting not only your initial budget but also the long-term value and maintenance of your building.

Floor Trusses: Higher Upfront, Long-Term Value

Investing in floor trusses typically means a higher initial outlay. This is due to several factors: the engineering expertise required for their design, the precision manufacturing process in a controlled factory environment, and the specialized transportation often needed to deliver these large components to your job site. These elements contribute to a greater upfront investment compared to raw lumber.

However, this initial expense is frequently offset by significant long-term savings and added value. The open web design drastically simplifies and speeds up the installation of crucial mechanical systems like plumbing, electrical wiring, and HVAC ducts. This efficiency translates directly into reduced labor costs for these trades. Furthermore, the inherent strength and engineered stability of trusses mean fewer instances of squeaking floors, sagging, or other structural issues over the lifespan of the building, minimizing future repair and maintenance expenses. Their ability to create large, open spaces also adds significant resale value and design appeal to a property.

Floor Joists: Budget-Friendly, Potential Future Costs

Floor joists are generally the more economical choice at the initial stages of a project. The materials (standard lumber) are widely available and typically less expensive per unit than custom-engineered trusses. The installation process for joists is also less complex, requiring basic carpentry skills and tools rather than specialized equipment like cranes, which can lower immediate labor costs and reduce equipment rental fees.

Despite the lower upfront cost, homeowners and builders should be mindful of potential future expenses. The solid nature of joists can complicate utility routing, often requiring skilled labor to drill or notch without compromising integrity, which adds to the cost and time of plumbing, electrical, and HVAC installations. Over time, traditional solid lumber joists can be more susceptible to natural wood characteristics like shrinking, twisting, or warping, potentially leading to issues such as squeaky floors or uneven surfaces, which may require costly repairs. While durable, their long-term performance can be more sensitive to moisture changes and environmental factors, potentially increasing maintenance needs.

Installation Procedures Explained

The installation method is a key differentiator that impacts project timelines, labor requirements, and overall efficiency. Understanding these processes helps in planning and managing your construction schedule.

Floor Trusses Installation

The installation of floor trusses is a highly efficient, multi-step process that leverages prefabrication for speed and precision.

Step 1: Prefabrication. Unlike traditional lumber, floor trusses are meticulously engineered and constructed off-site in a controlled factory environment. This process follows exact architectural plans, ensuring high levels of accuracy, consistency, and quality control. Each truss is designed to specific load requirements and spans, pre-cut, and assembled using metal connector plates, ready for immediate installation upon delivery.

Step 2: Delivery to Site. Once manufactured, the completed trusses are carefully transported to your construction site. Due to their size, this often requires specialized trucks and coordinated logistics to ensure they arrive undamaged and ready for immediate placement.

Step 3: Positioning. This is typically the most visually dramatic step. Given their size and weight, cranes or other heavy lifting equipment are often employed to lift the prefabricated trusses from the delivery truck and precisely position them over the prepared support walls or beams. This rapid placement significantly speeds up the framing process compared to individual piece-by-piece installation.

Step 4: Securing the Trusses. Once positioned, skilled workers meticulously fasten each truss to the building’s frame. This involves using specified hangers, hurricane ties, or other connection hardware to ensure they are properly aligned, level, and securely anchored to the supporting structure, providing maximum stability and load transfer.

Step 5: Final Adjustments. Before the subflooring is laid, minor adjustments may be made to ensure every truss is perfectly level and square. Bracing might also be added temporarily or permanently, according to engineering specifications, to maintain alignment and prevent lateral movement during construction and throughout the building’s life. This rigorous final check guarantees optimal structural performance.

Floor Joists Installation

The installation of floor joists is a more labor-intensive, on-site process, relying heavily on traditional carpentry skills.

Step 1: Material Delivery. Raw lumber, typically in standard lengths, is delivered directly to the construction site. This lumber is then stored and protected from the elements until needed.

Step 2: Measuring and Marking. Builders carefully measure the spans where the joists will be installed. Each joist is then marked according to the architectural layout, indicating cut points and placement along the sill plates or beams. This step requires precision to ensure the structural integrity and uniformity of the floor.

Step 3: Cutting to Size. Unlike prefabricated trusses, each joist must be individually cut on-site to fit the exact required length for its specific location within the floor system. This can generate significant waste and requires accurate cutting equipment.

Step 4: Placement and Spacing. Cut joists are then manually placed across the frame, resting on ledger boards or joist hangers. Maintaining consistent spacing between each joist (typically 16 or 24 inches on center) is crucial for distributing loads evenly and ensuring the floor’s strength and stability. Proper spacing also allows for standard subfloor sheet dimensions.

Step 5: Securing the Joists. Workers fasten each joist one by one, typically using nails or screws, into the supporting members. Joist hangers are often used to provide robust connections where joists meet beams or other structural elements, ensuring they are level, square, and securely anchored.

Step 6: Adjustments and Fine-Tuning. Throughout the installation, builders make real-time adjustments for any irregularities in lumber or site-specific issues. This includes shimming to achieve a level surface, checking plumb and square, and ensuring all connections meet building code requirements. This iterative process is crucial for achieving a stable and flat subfloor ready for finishes.

Debunking Common Misconceptions

When planning a building project, it’s common to encounter various claims and myths about construction materials and methods. Clearing up these misunderstandings about floor systems can help you make a more informed and rational decision.

Trusses Are for Large Projects Only

A prevalent misconception is that floor trusses are exclusively reserved for large-scale commercial buildings, expansive industrial facilities, or custom luxury homes with exceptionally long spans. While it’s true that trusses excel in these demanding environments, this belief often overlooks their significant utility and advantages in standard residential construction. Trusses are increasingly being adopted in average-sized homes, townhouses, and even multi-family dwellings. They are particularly beneficial when homeowners desire an open floor plan, require easy integration of modern large-scale HVAC systems, or simply want to minimize future maintenance issues related to squeaks or sagging.

Their custom engineering allows them to be tailored to virtually any project size and specific design requirement, making them a versatile option that can enhance the quality and efficiency of a wide range of building endeavors, not just the monumental ones. The long-term benefits in utility access and structural stability often justify their initial cost, even for more modest homes.

Joists Lack Durability

Another common misunderstanding suggests that because floor joists have a simpler, more traditional design, they are inherently less durable or structurally inferior to engineered trusses. This is far from accurate. When properly sized, correctly installed, and adequately maintained, high-quality floor joists made from solid lumber or engineered wood products like I-joists can provide exceptional structural support and last for many decades, often for the entire lifespan of the building. Countless homes built over the last century stand as testament to the enduring durability of traditional joist systems.

The key to joist longevity lies in several factors: using appropriate lumber species and grades, ensuring correct spacing and span calculations, proper fastening, and critically, protecting them from moisture, pest infestation, and excessive loads. Regular inspections for any signs of water damage, rot, or insect activity are essential for extending their life. For typical residential loading conditions and standard architectural designs, joists remain a remarkably reliable, cost-effective, and time-tested choice that continues to be trusted by builders worldwide.

Longevity and Maintenance: What to Expect

The long-term performance and maintenance requirements of your chosen floor system are critical considerations, impacting both your comfort and potential repair costs over the life of the building. Understanding these aspects will aid in making a truly complete and informed decision.

Floor Trusses: Engineered for Enduring Performance

Floor trusses are engineered with an emphasis on dimensional stability and enduring performance. Their factory-controlled fabrication process and precise assembly, using kiln-dried lumber and robust metal connector plates, result in a highly stable product. This engineered design significantly reduces the likelihood of common issues associated with traditional lumber, such as warping, twisting, shrinking, or sagging over time. The triangulated web system distributes loads more uniformly, minimizing concentrated stress points and thereby preventing common problems like floor squeaks.

Their inherent stability means that once installed correctly, floor trusses typically require very little ongoing maintenance related to their structural integrity. They are less reactive to changes in humidity and temperature, leading to a consistently flat and stable subfloor. This translates into fewer callbacks for builders, lower long-term maintenance costs for homeowners, and a more comfortable, reliable floor system for the entire lifespan of the structure.

Floor Joists: Traditional, with Specific Care Needs

Solid wood floor joists, while durable and capable of lasting for many decades, require more attention and specific care to maintain their integrity over time. Being natural wood products, they are more susceptible to the effects of environmental factors. Changes in humidity can cause solid lumber to expand, contract, or even warp, which can lead to issues like floor squeaks, unevenness, or cracks in finished flooring.

Regular inspections are vital for joist systems to identify and address potential problems early. This includes checking for signs of moisture infiltration, which can lead to wood rot or mold growth, particularly in basements or crawl spaces. Pest infestations, such as termites or carpenter ants, can also severely compromise the structural integrity of wood joists. Prompt repair or replacement of any damaged joists is crucial to prevent more widespread structural issues. While proper treatment and protection during installation can extend their life, the natural characteristics of wood mean that a joist system demands a more proactive approach to long-term maintenance compared to engineered trusses.

Making Your Informed Decision

The final choice between floor trusses and floor joists is not about which option is inherently “better,” but rather which system is the optimal fit for your specific project’s unique requirements, budget constraints, and desired outcomes. Both systems offer reliable support when correctly installed and maintained, each with its own set of distinct advantages.

When to Choose Floor Trusses

Opt for floor trusses if your project involves:

- Longer Spans: You desire large, open-concept spaces without the need for interior bearing walls or columns.

- Complex Designs: Your architectural vision includes vaulted ceilings, custom floor layouts, or intricate structural requirements.

- Extensive Utilities: Your plans involve a significant amount of plumbing, electrical wiring, or large HVAC ductwork, where ease of integration is paramount.

- Long-Term Value: You prioritize minimizing future maintenance costs, avoiding squeaky floors, and enhancing the structural stability and resale value of your property.

- Faster Framing: You are working with a tight construction schedule and can utilize specialized equipment for rapid installation.

When to Choose Floor Joists

Choose floor joists if your project aligns with:

- Budget Sensitivity: You have a more conservative upfront construction budget and are seeking cost-effective material and labor solutions.

- Standard Designs: Your home design features traditional room sizes and a straightforward, conventional layout.

- Simpler Utility Needs: Your utility requirements are minimal or can be easily accommodated with standard drilling practices without compromising structural integrity.

- Familiarity and Availability: You prefer a time-tested construction method with readily available materials and a familiar installation process for local contractors.

- DIY or Small Crews: Your project relies on smaller crews or manual installation without the need for heavy lifting equipment.

Conclusion

The decision between floor trusses and floor joists is a pivotal one that influences the structural integrity, functionality, and long-term cost of your building project. Floor trusses stand out for their exceptional ability to span greater distances, offer unparalleled design flexibility, and simplify utility integration, providing significant long-term value despite a higher initial cost. Floor joists, conversely, are celebrated for their cost-effectiveness, straightforward installation, and reliability in traditional, standard designs.

Ultimately, the “best” choice is the one that most effectively meets your project’s specific needs, budget constraints, and architectural aspirations. By carefully considering factors such as span requirements, load-bearing capacity, utility integration, design complexity, initial and long-term costs, and installation logistics, you can make an informed decision that ensures a stable, durable, and functional floor system for years to come. Regardless of your focus—be it cost efficiency, design freedom, or enduring performance—prioritize the system that aligns perfectly with your vision for a successful and satisfying build.

Looking for more helpful insights on home building, renovation tips, and construction best practices? Explore our other informative blogs available on our website to further empower your building journey.

I have rewritten the content, expanded it to over 900 words, ensured it is SEO-friendly with a clear `