Mastering DIY Shaker Cabinet Doors: Your Complete Guide to Building & Installing Affordable Kitchen Upgrades

Welcome, fellow DIY enthusiast! Are you dreaming of a kitchen refresh without the hefty price tag? You’re in the right place. I’ve personally guided countless friends through the process of updating their kitchens, and I can tell you from experience that crafting your own shaker cabinet doors is far simpler and more rewarding than you might imagine.

The biggest perk? Taking on this project yourself can result in significant cost savings, often hundreds or even thousands of dollars compared to purchasing custom or pre-made doors. Beyond the financial benefits, there’s an immense sense of pride that comes with stepping into a kitchen where every detail, especially the beautiful, clean-lined cabinetry, reflects your own handiwork.

This guide will meticulously walk you through every single step, from selecting the right materials to the final installation. Having started as a complete beginner myself, I understand the common pitfalls and the most effective tips and tricks to ensure your success. You don’t need years of woodworking experience or a professional workshop to achieve stunning, professional-looking results.

Ready to embark on a journey that will not only revitalize your kitchen but also equip you with valuable new skills? Let’s gather our tools, select our materials, and begin crafting the shaker cabinet doors that will transform your space.

Understanding the Timeless Appeal of Shaker Cabinet Doors

Before diving into construction, it’s helpful to understand what makes shaker cabinet doors so universally loved and incredibly suitable for DIY projects. My own journey through various cabinet styles always led me back to shaker, and for good reason.

At their core, shaker doors are defined by their elegant simplicity: a flat, recessed center panel surrounded by a clean, unadorned frame. There are no intricate carvings, raised panels, or complex details – just straightforward, functional design. This minimalist aesthetic is deeply rooted in the Shaker movement of the 18th century, emphasizing utility, honesty of materials, and impeccable craftsmanship, which still resonates in modern design today.

What truly sets these doors apart is their remarkable versatility. Whether your home boasts a sleek, contemporary aesthetic, a cozy farmhouse vibe, or a more traditional look, shaker doors integrate seamlessly. Their clean lines offer a sophisticated backdrop that complements various color palettes and hardware styles, ensuring they never go out of fashion. From a compact city apartment to a spacious suburban home, shaker cabinets provide a foundation of timeless style that effortlessly enhances any kitchen.

But here’s the real kicker for us DIYers: their simple design significantly reduces the complexity often associated with woodworking projects. Fewer intricate cuts and less elaborate joinery mean a much lower probability of mistakes and a higher chance of achieving a polished, professional outcome. You won’t need specialized, expensive tools or years of practice to make these doors look like they came straight from a high-end custom shop.

Selecting the Right Materials for Durability and Finish

The success of your DIY shaker cabinet doors hinges significantly on the quality and type of materials you choose. Opting for the right components will ensure not only a beautiful finish but also long-lasting durability. Here’s a detailed breakdown:

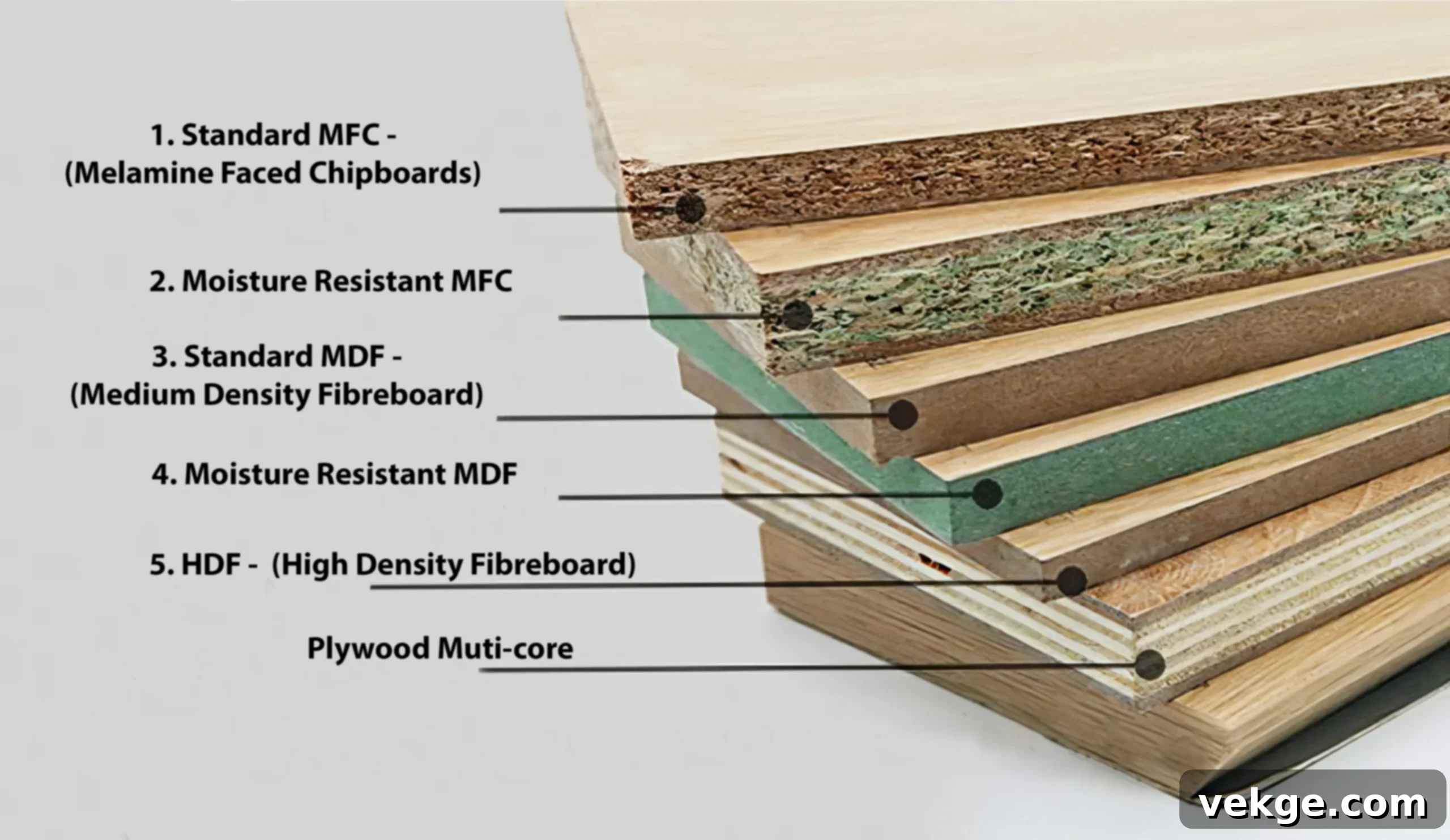

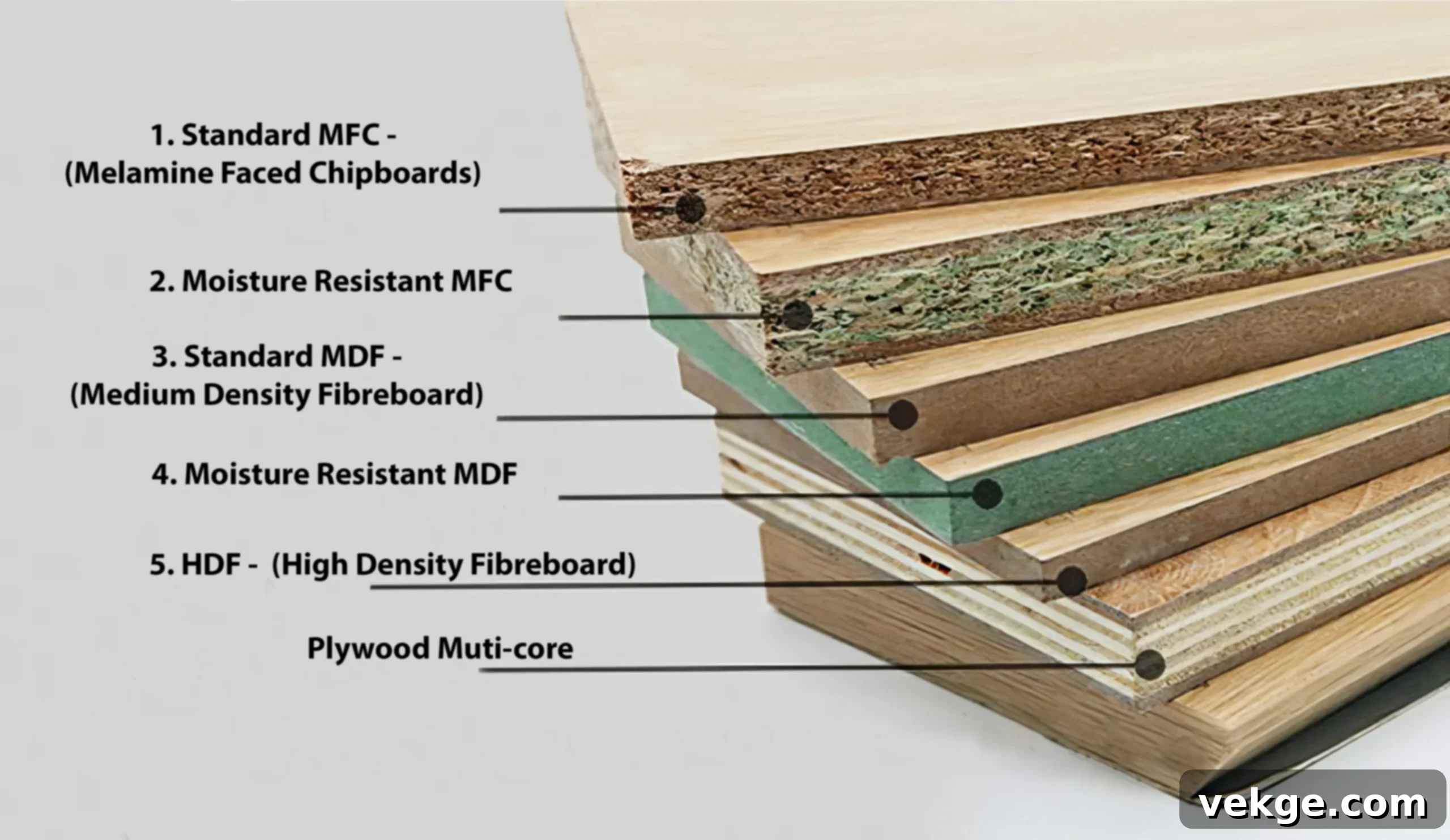

1. Main Panel Material: MDF vs. HDF

- MDF (Medium Density Fiberboard): This is my go-to choice, especially for painted cabinets, primarily due to its cost-effectiveness and excellent finish properties. MDF is incredibly flat, smooth, and uniform, which means it takes paint exceptionally well, resulting in a flawless, glass-like surface without any visible wood grain. Its stability also prevents warping and cracking, common issues with solid wood in fluctuating kitchen environments. I recommend a 1/2-inch thickness for good strength and stability in your door frames.

- HDF (High Density Fiberboard): HDF is a denser, heavier, and generally more expensive alternative to MDF. Its higher density makes it more resistant to moisture, which can be an advantage in high-humidity areas, and it offers superior impact resistance. However, it’s harder to cut and sand. For most painted cabinet applications, MDF provides sufficient performance at a more attractive price point. Both are excellent choices for achieving a smooth, painted finish.

2. Center Panel Choice

- 5mm (3/16 inch) Plywood: This thickness is ideal for the recessed center panel. Plywood is dimensionally stable, meaning it resists warping and shrinking better than solid wood, which is crucial for a flat, unmoving panel. It’s also light enough to prevent undue stress on the frame joints and fits perfectly into standard dado cuts. The slight flexibility of plywood also allows it to “float” within the frame, accommodating minor seasonal changes without causing the door to buckle.

- Avoid Hardwood Panels: While beautiful, solid hardwood panels are not recommended for the recessed center of a shaker door, especially for DIY beginners. Hardwood naturally expands and contracts with changes in humidity, which can lead to cracking, warping, or putting immense stress on the frame joints, ultimately compromising the door’s integrity and appearance. They are also significantly more expensive.

3. Glue Selection

- Standard Wood Glue: A high-quality, moisture-resistant wood glue (like Titebond III) is perfect for assembling your door frames. Look for reputable brands known for strong bonds. You’ll be surprised how far one bottle goes; typically, it’s enough for 15-20 doors. The moisture resistance is vital in a kitchen environment where spills and humidity are common.

4. Paint Picks

- Cabinet-Grade Paint: Do not skimp on paint! Invest in a high-quality, cabinet-grade paint designed for kitchen use. These paints are formulated for superior durability, hardness, and a smooth, professional finish that resists chipping, scratching, and yellowing. Many cabinet paints are also self-leveling, which helps minimize brush marks for a factory-like appearance. You’ll typically need enough for 2-3 coats, including a good primer. Always sample your chosen color on a scrap piece of your material first to ensure it matches your vision.

- Primer: A high-quality primer specifically designed for MDF is essential. It seals the porous surface of the MDF, prevents uneven absorption of topcoats, and provides a durable base for your paint, enhancing adhesion and finish quality.

5. Hardware Tips

- Soft-Close Hinges: These are a must for any modern kitchen. Soft-close hinges prevent slamming, protect your doors and cabinets from wear, and add a touch of luxury. While slightly more expensive, they are a worthwhile investment in the longevity and user experience of your cabinets.

- Quality Screws: Cheap screws strip easily, especially when working with MDF. Invest in good quality, self-tapping screws for your hinges and pulls to ensure secure installation and prevent headaches.

- Door Pulls/Knobs: Choose hardware that complements your home’s overall style and your new shaker doors. They are the jewelry of your cabinets and can significantly influence the final look.

- Buy Extras: It’s always a good idea to purchase a few extra hinges, screws, and pulls. Mistakes happen, and having spares on hand avoids frustrating delays.

How to DIY Shaker Cabinet Doors: A Step-by-Step Guide

This section will guide you through the process of constructing your shaker cabinet doors. We’ll cover everything from precise cuts to assembling the frame, ensuring a strong and beautiful result.

Tools & Materials Required

Before you begin, ensure you have all the necessary tools and materials at hand. Good preparation saves time and reduces frustration.

| Tools Required | Materials Required |

|---|---|

| Table saw (essential for precise, straight cuts) | MDF (Medium Density Fiberboard) sheets – 1/2 inch thickness (for door frames) |

| Miter saw or miter gauge (for accurate crosscuts on rails/styles) | 5mm (3/16 inch) plywood for center panels (stable and lightweight) |

| Power drill (for drilling pilot holes and assembling) | Wood glue (moisture-resistant is best) |

| Impact driver (optional, but great for driving screws) | Soft-close hinges (for quiet and gentle closing) |

| Stop block (for repetitive, identical cuts) | Cabinet door pulls or knobs (personalize your doors) |

| Measuring tape (measure twice, cut once!) | Screws (high-quality, non-stripping) |

| Sanding block and sandpaper (various grits for smooth finish) | Painters tape (for clean paint lines) |

| Clamps (F-clamps, parallel clamps for strong joints) | Rubber bumpers (protect frames from impact) |

| Drill bits (including Forstner bit for hinge cups) | Paint and primer (cabinet-grade for durability) |

| Roller support for sheet goods (aids in safe table saw use) | Caulk (paintable, for filling small gaps) |

| Cabinet hardware installation jig (highly recommended for consistency) | |

| Drawer face clamps (if making drawers, for precise alignment) | |

| Level (for ensuring straight installations) |

Step-by-Step Construction Process

1. Measure & Plan for Precision

- Begin by accurately measuring each cabinet opening (width and height). Remember to subtract a small clearance (e.g., 1/8 inch total for height and width) to ensure the doors don’t bind.

- Determine the desired width of your rails (horizontal pieces) and stiles (vertical pieces). A common width for shaker doors is 2.25 inches, providing a classic, balanced look.

- Calculate the exact dimensions for each door’s components: two stiles, two rails, and one center panel. This planning stage is critical to avoid costly mistakes.

2. Cut Components with Care

- Using your table saw, rip your 1/2-inch MDF sheets into strips for your rails and stiles, all at your chosen width (e.g., 2.25 inches). Safety first: use a push stick and roller supports.

- Next, use your miter saw or table saw with a miter gauge to cut the stiles to their final length (this will be the full height of your door).

- Cut the rails to length. This requires a bit of calculation: the rail length is the total door width minus the width of both stiles, plus any material needed for your joinery (e.g., if using a dado and tenon style, add the tenon length).

- Cut your 5mm plywood center panels. The panel should be cut slightly smaller (approximately 1/8 inch less in both width and height than the inside dimensions of your assembled frame) to allow it to “float” within the dados, preventing warping due to humidity changes and eliminating rattling.

- It’s a good practice to cut a few extra pieces of rails, stiles, and panels as backup for test cuts or in case of errors.

3. Create Dados for Floating Panels

- Set up your table saw with a dado blade (or make multiple passes with a regular blade) to cut a groove (dado) along the inside edge of all your rail and stile pieces. This dado should be centered and approximately 3/8 inch deep, sized to perfectly fit your 5mm (3/16 inch) plywood center panels.

- Always test your dado setup on a scrap piece of MDF first to ensure the correct depth and width for a snug, but not overly tight, fit for your panel.

- Carefully cut dados into all the interior edges of your rail and stile components. These grooves will securely hold the floating center panel.

4. Assemble Frame Joints

- For DIY-friendly shaker door construction, a common and effective method for joining the frame (rails to stiles) is using pocket hole joinery. This creates strong, hidden joints.

- Using a pocket hole jig, drill pocket holes on the ends of your rail pieces. These holes will be used to screw the rails into the stiles.

- Alternatively, you can use simple butt joints reinforced with wood glue and screws, or dowels for a cleaner look if you prefer to hide fasteners.

- Before applying glue, dry-fit all your frame components together with the center panel to ensure everything aligns perfectly and the panel floats freely within the dados. Sand any edges or adjust cuts slightly if needed for a perfect fit.

5. Panel Preparation (Optional, but Recommended)

- While not strictly necessary, slightly beveling or chamfering the edges of your center panels can make them easier to insert into the dados during assembly and creates a subtle, refined look. It also helps prevent paint from building up excessively on the sharp edges.

- Ensure your panels are clean and free of dust before assembly.

6. Secure Assembly

- Apply a moderate amount of wood glue into the dados of your stiles and rails. Also apply glue to the end grain of the rails where they meet the stiles (if using butt joints or pocket holes).

- Carefully insert the center panel into the dados of one stile and one rail. Then, join the opposite stile and rail, essentially building the frame around the floating panel. Remember, the center panel itself should not be glued into the dados, allowing it to move slightly.

- Clamp the entire frame together, ensuring all corners are square. Use corner clamps or ensure your parallel clamps are applying even pressure. Wipe off any excess glue squeeze-out immediately with a damp cloth.

- Let the doors dry completely according to your wood glue manufacturer’s instructions, typically for several hours or overnight, before removing clamps.

7. Surface Preparation for a Flawless Finish

- Once the glue is fully cured, it’s time for sanding. Start with 120-grit sandpaper to remove any dried glue or imperfections, then move to 180-grit, and finally 220-grit for a super smooth finish. Pay special attention to the joints to ensure they are perfectly flush.

- Wipe all surfaces thoroughly with a damp cloth or tack cloth to remove every speck of dust.

- Apply a bead of paintable caulk along any tiny gaps at the frame joints or where the center panel meets the frame. This creates a seamless, high-end look once painted. Allow the caulk to dry completely.

- Apply a high-quality primer designed for MDF. MDF edges tend to be very absorbent, so apply extra primer to the edges to ensure an even finish. Allow primer to dry and lightly sand with 220-grit if needed, then wipe clean.

8. Hardware Installation Prep

- Once primed and painted (after two to three thin coats, allowing ample drying time and light sanding between coats), mark the exact locations for your hinges. Using a hinge installation jig will ensure consistent placement across all your doors.

- Use a Forstner bit to drill the appropriate-sized holes (typically 35mm) for your soft-close hinge cups. Ensure the depth is correct to avoid drilling through the front of the door.

- Install the hinges onto the doors.

- Mark and drill pilot holes for your door pulls or knobs.

9. Door Mounting (See Detailed Installation Section Below)

- This final step involves attaching your newly constructed doors to your cabinet frames. While it’s covered in more detail in a dedicated section below, the core idea is to use spacer blocks for consistent alignment, mount the doors to the cabinets, and then make fine adjustments to ensure perfect gaps and smooth operation.

Approximate Budget Analysis for Your DIY Shaker Cabinet Doors

One of the most compelling reasons to build your own cabinet doors is the significant cost savings. While prices can vary based on location and material choices, here’s a general breakdown to help you plan your budget:

| Item | Quantity/Unit | Estimated Cost Range |

|---|---|---|

| Core Materials | ||

| MDF sheets (4×8 ft, 1/2-inch thickness) | Per sheet | $35 – $45 |

| 5mm plywood for panels (4×8 ft) | Per sheet | $25 – $30 |

| Wood glue | Per bottle (16 oz) | $5 – $8 |

| Hardware | ||

| Soft-close hinges | Per pair | $3 – $5 |

| Door pulls/knobs | Each | $2 – $8 |

| Screws and mounting hardware | Total | $10 – $15 |

| Rubber bumpers | Per pack | $5 |

| Finishing Materials | ||

| Primer | Per gallon | $20 – $25 |

| Paint (cabinet-grade) | Per gallon | $25 – $35 |

| Caulk | Per tube | $4 – $6 |

| Sandpaper (mixed grits) | Mixed grits | $10 – $15 |

| Total Cost by Kitchen Size (Estimated for materials only, excluding tools) | ||

| Small Kitchen (10-15 doors) | $200 – $300 | |

| Medium Kitchen (15-25 doors) | $300 – $400 | |

| Large Kitchen (25+ doors) | $400 – $500 | |

Compare these figures to the cost of purchasing pre-made or custom shaker doors, which can easily run $50-$150 per door. The savings are substantial, making this a highly cost-effective renovation project.

Money-Saving Tips for Your Project

- Buy Hardware in Bulk: If you have many doors, purchasing hinges and pulls in larger packs or quantities can significantly reduce the per-unit cost. Check online retailers for bulk discounts.

- Use Leftover Paint from Other Projects: If you’ve recently painted walls or other furniture, you might have primer or paint that can be repurposed for your doors, especially for smaller accent pieces or a first coat.

- Get MDF Sheets Cut at the Store: Many lumber yards or home improvement stores offer cutting services. Having large sheets cut down into more manageable strips can save you time, reduce waste, and improve safety if you’re not confident with ripping on a table saw.

- Share Supplies with Other DIY Friends: If you know others undertaking similar projects, consider pooling resources for bulk purchases of sandpaper, glue, or even renting specialized tools together.

- Look for Sales: Keep an eye out for sales on wood glue, primer, and paint at your local hardware stores.

How to Install Your New Shaker Doors for a Perfect Fit

Installing your newly crafted shaker doors is the final, rewarding step. Proper installation ensures that your doors not only look fantastic but also function smoothly and close perfectly. Precision here makes all the difference.

Before You Start

- Clear Your Workspace: Ensure the area around your cabinets is free of clutter to move freely and safely.

- Keep Doors Organized: If you made doors of different sizes, label each door for its specific cabinet opening. This prevents confusion and rework.

- Have All Tools Within Reach: Gather your drill, driver bits, installation jig, measuring tape, and level.

- Label Each Door’s Location: A small pencil mark on the back of each door indicating “U-L” (Upper Left) or “B-R” (Bottom Right) can save immense time during installation.

Step 1: Prepare the Cabinet Frame

- Clean Old Screw Holes: If replacing existing doors, clear out any debris from previous screw holes.

- Sand Rough Spots: Lightly sand any rough areas on the cabinet face frame that might interfere with the new doors.

- Check Cabinet Frame Level: Use a level to ensure your cabinet frames are plumb and level. Adjustments here will make door alignment much easier.

- Mark Hinge Locations: Use your cabinet hardware installation jig to precisely mark where the hinges will attach to the cabinet face frame. Consistency is key for a professional look.

Step 2: Install Hinges on Doors

- Attach Hinges to Doors First: It’s generally easier to install the hinges onto the doors first, using the pre-drilled hinge cup holes.

- Set Depth with 3mm Spacing: Modern concealed hinges often come with adjustments for overlay and depth. Set them to allow a consistent 3mm (approx. 1/8 inch) gap around the door.

- Use a Template for Consistency: A dedicated hinge jig ensures all hinges are installed at the same height on each door, crucial for even alignment.

- Test-Fit Before Final Install: Briefly attach a door to ensure the hinge operates correctly and the door swings freely before fully tightening all screws.

Step 3: Door Mounting to Cabinets

- Start with Upper Cabinets: Begin mounting doors on your upper cabinets. It’s often easier to work from top to bottom.

- Use a Helper if Possible: Mounting doors, especially larger ones, is significantly easier and safer with a second person to hold the door in place while you screw in the hinges.

- Place Spacer Blocks Under Doors: For base cabinets, use small spacer blocks (e.g., 1/8 inch or a stack of shims) to lift the door slightly off the cabinet base, ensuring consistent floor clearance. For upper cabinets, align with the bottom of the cabinet.

- Check Gaps Are Even All Around: As you attach each hinge, check that the gaps between the door and the cabinet frame (and adjacent doors) are consistent. Make minor adjustments before fully tightening the screws.

Step 4: Making Adjustments for Perfection

- Check Door Alignment: Once all doors are hung, stand back and observe. Are they perfectly straight and aligned with each other?

- Fix Any Gaps: Most soft-close hinges offer three-way adjustments (in/out, up/down, left/right). Use these adjustments to fine-tune the door’s position until all gaps are even and consistent. This step takes patience but is essential for a high-quality finish.

- Test Door Swing: Open and close each door several times to ensure smooth operation and that they don’t bind or rub against the cabinet frame or adjacent doors.

- Look for Binding Spots: If a door sticks, identify the rubbing point. It might require further hinge adjustment or a very light sanding if it’s a minor contact point.

Step 5: Final Touches and Enjoyment

- Put on Rubber Bumpers: Adhere small, clear rubber bumpers to the inside corners of the door (the side that closes against the cabinet frame). These absorb shock, reduce noise, and prevent the door from hitting the frame directly.

- Add Door Pulls or Knobs: Install your chosen hardware. A hardware jig is invaluable for ensuring consistent placement across all doors.

- Test Soft-Close Function: Give each door a gentle push to ensure the soft-close mechanism is working correctly.

- Clean Fingerprints: Wipe down all your newly installed doors to remove any fingerprints or smudges from the installation process.

Pro Tips for Installation Success

- Make a Guide Stick for Spacing: Cut a small strip of wood to your desired gap size (e.g., 1/8 inch). Use this as a consistent spacer when hanging doors.

- Go Slow – Rushing Causes Mistakes: Take your time with each step, especially with measurements and adjustments. A few extra minutes now can save hours of rework later.

- Adjust One Hinge at a Time: When fine-tuning, focus on one adjustment screw on one hinge, then check the result before moving to the next.

- Double-Check All Screws Are Tight: Ensure all hinge and hardware screws are securely fastened for long-term durability.

Some Common Issues and Solutions to Look After

Even with careful planning, DIY projects can present challenges. Here are some common issues you might encounter when building or installing shaker cabinet doors, along with their practical solutions:

| Issue Category | Specific Problem | Potential Fix |

|---|---|---|

| Doors Not Closing Right | Gaps aren’t even around the door. | Adjust hinge screws (most concealed hinges have 3-way adjustments for side-to-side, in/out, and up/down movement). Ensure the cabinet frame is level and plumb. Add/remove spacers behind hinge plates if frame is uneven. Check for debris in hinge mechanisms. |

| The door hits the cabinet frame. | ||

| Door won’t close fully, or springs back. | ||

| Paint Problems | Brush marks or roller texture show. | Sand meticulously between coats (220+ grit). Use a high-quality, self-leveling cabinet-grade paint and an appropriate roller/brush for a smooth finish. Ensure proper primer application to seal MDF. Apply thin, even coats and allow each to dry completely. For peeling, ensure surfaces were clean and primed properly before painting. |

| Paint peels or chips easily. | ||

| Uneven finish or splotches. | ||

| Joint Issues | Gaps visible in corner joints (rails to stiles). | Ensure cuts are perfectly square. Use ample wood glue and clamp properly (and squarely) during assembly. For pocket hole joints, ensure screws are fully tightened. Fill minor gaps with paintable caulk after assembly and before priming. For rattling panels, ensure the dado is the correct size and the panel floats, then add a small bead of caulk or a thin shim if needed (though a floating panel should not be glued). |

| Loose joints after drying. | ||

| Center panel rattles within the frame. | ||

| Panel Fitting Problems | Center panel is too tight in the frame. | Ensure the panel is cut precisely 1/8 inch smaller than the interior frame dimensions to allow for expansion. Lightly sand the panel edges. Verify your dado cuts are the correct width and depth. Ensure your initial cuts for the panel are perfectly square. If a panel warps, it might be due to moisture exposure or not allowing it to acclimate to your shop’s humidity. |

| Center panel warps after assembly. | ||

| Panel makes squeaking sounds when door opens/closes. |

General Tips for Success

- Make Test Pieces First: Always make test cuts and practice joinery on scrap pieces before cutting your final materials. This is especially important for dado blade setups.

- Check Fits Before Gluing: Dry-fit every component before applying glue. Once glue is applied, you have limited time for adjustments.

- Keep the Work Area Clean: A clean and organized workspace not only improves safety but also helps maintain accuracy and prevents dust from contaminating finishes.

- Take Breaks to Avoid Mistakes: Woodworking requires focus. If you feel tired or frustrated, step away for a break. A fresh perspective can prevent costly errors.

Conclusion: The Reward of Crafting Your Own Kitchen Masterpiece

As you’ve now seen, making your own shaker cabinet doors is far from the daunting task it might initially appear to be. Through years of assisting friends with their kitchen transformations, I’ve witnessed firsthand the incredible impact these simply designed, yet profoundly elegant, doors can have on a room’s entire aesthetic.

The key to your success lies in two fundamental principles: patience and precision. Take your time with every measurement, every cut, and every assembly step. Each stage builds upon the last, and careful execution will result in doors that look professionally made and last for years to come. Should you encounter any snags along the way, remember the troubleshooting solutions provided above – they’re designed to guide you through common challenges.

Are you feeling ready to kickstart your own kitchen cabinet project? Gather your materials, prepare your workspace, and consider enlisting a friend for an extra set of hands – it makes the process even more enjoyable. The financial savings you’ll achieve are a significant benefit, but the immense satisfaction and pride of stepping back, admiring your newly transformed kitchen, and proudly declaring, “I made these!” truly feels even better.

Do you have any questions about your specific cabinet project, or perhaps a tip you’ve discovered that could benefit others? Please don’t hesitate to leave a comment below. I’d absolutely love to hear about your journey and how your beautiful new shaker doors turn out!

Frequently Asked Questions About Shaker Cabinet Doors

What is the Difference Between a Panel Door and a Shaker Door?

A “panel door” is a broad term for any door constructed with a frame (stiles and rails) and one or more recessed or raised panels. A “shaker door” is a specific type of panel door characterized by its extreme simplicity: it features a flat, recessed center panel surrounded by a very clean, unadorned frame. Unlike more ornate panel doors, shaker doors have no bevels, curves, or decorative edges, emphasizing functionality and minimalist aesthetics.

Are Shaker Cabinet Doors Suitable for All Kitchen Styles?

Yes, shaker cabinet doors are remarkably versatile and are considered one of the most adaptable styles in kitchen design. Their clean, simple lines allow them to complement a vast array of kitchen aesthetics, from ultra-modern and contemporary to traditional, farmhouse, industrial, and transitional styles. While they may not suit highly ornate or intricately detailed decors, for most homes, shaker doors provide a timeless and sophisticated foundation that can be easily accessorized with different hardware and finishes.

Can You Make Shaker Doors out Of Plywood?

Absolutely, yes! Plywood is an excellent and cost-effective material for making shaker doors, particularly for the center panels, as discussed in the materials section. For the frame (stiles and rails), you can also use plywood strips, though MDF is often preferred for a completely smooth, grain-free painted finish. Using plywood throughout can make the project more budget-friendly and still yield durable, attractive doors, especially if you plan to paint them.

Why are Shaker Doors so Expensive?

The perceived high cost of shaker doors in retail or custom shops often stems from several factors: the use of high-quality, solid wood for the frames (which requires careful selection and milling), precise craftsmanship to ensure perfectly square and tight joints (especially for traditional cope-and-stick joinery), and the labor involved in their construction and finishing. While their design is simple, achieving that clean, minimalist look professionally demands accuracy and attention to detail, which increases labor costs. Custom or high-end options will naturally be pricier due to bespoke sizing and premium materials.

How Do You Make Shaker Cabinet Doors without a Router?

Making shaker doors without a router is entirely possible for the DIY enthusiast. Instead of using router bits for cope-and-stick joinery or precise dado cuts for the frame assembly, you can use simpler methods. For the frame, you can use butt joints reinforced with wood glue and screws (often hidden with pocket holes from a pocket hole jig) or dowels. To create the recess for the center panel, you can either cut a shallow dado with multiple passes on a table saw (as described in this guide) or use a thin, flat center panel and attach the frame pieces directly to it, creating a “faux” shaker style where the panel isn’t floating but glued/nailed in place. This simplifies construction significantly for beginners.

Mastering DIY Shaker Cabinet Doors: Your Complete Guide to Building & Installing Affordable Kitchen Upgrades

Welcome, fellow DIY enthusiast! Are you dreaming of a kitchen refresh without the hefty price tag? You’re in the right place. I’ve personally guided countless friends through the process of updating their kitchens, and I can tell you from experience that crafting your own shaker cabinet doors is far simpler and more rewarding than you might imagine.

The biggest perk? Taking on this project yourself can result in significant cost savings, often hundreds or even thousands of dollars compared to purchasing custom or pre-made doors. Beyond the financial benefits, there’s an immense sense of pride that comes with stepping into a kitchen where every detail, especially the beautiful, clean-lined cabinetry, reflects your own handiwork.

This guide will meticulously walk you through every single step, from selecting the right materials to the final installation. Having started as a complete beginner myself, I understand the common pitfalls and the most effective tips and tricks to ensure your success. You don’t need years of woodworking experience or a professional workshop to achieve stunning, professional-looking results.

Ready to embark on a journey that will not only revitalize your kitchen but also equip you with valuable new skills? Let’s gather our tools, select our materials, and begin crafting the shaker cabinet doors that will transform your space.

Understanding the Timeless Appeal of Shaker Cabinet Doors

Before diving into construction, it’s helpful to understand what makes shaker cabinet doors so universally loved and incredibly suitable for DIY projects. My own journey through various cabinet styles always led me back to shaker, and for good reason.

At their core, shaker doors are defined by their elegant simplicity: a flat, recessed center panel surrounded by a clean, unadorned frame. There are no intricate carvings, raised panels, or complex details – just straightforward, functional design. This minimalist aesthetic is deeply rooted in the Shaker movement of the 18th century, emphasizing utility, honesty of materials, and impeccable craftsmanship, which still resonates in modern design today.

What truly sets these doors apart is their remarkable versatility. Whether your home boasts a sleek, contemporary aesthetic, a cozy farmhouse vibe, or a more traditional look, shaker doors integrate seamlessly. Their clean lines offer a sophisticated backdrop that complements various color palettes and hardware styles, ensuring they never go out of fashion. From a compact city apartment to a spacious suburban home, shaker cabinets provide a foundation of timeless style that effortlessly enhances any kitchen.

But here’s the real kicker for us DIYers: their simple design significantly reduces the complexity often associated with woodworking projects. Fewer intricate cuts and less elaborate joinery mean a much lower probability of mistakes and a higher chance of achieving a polished, professional outcome. You won’t need specialized, expensive tools or years of practice to make these doors look like they came straight from a high-end custom shop.

Selecting the Right Materials for Durability and Finish

The success of your DIY shaker cabinet doors hinges significantly on the quality and type of materials you choose. Opting for the right components will ensure not only a beautiful finish but also long-lasting durability. Here’s a detailed breakdown:

1. Main Panel Material: MDF vs. HDF

- MDF (Medium Density Fiberboard): This is my go-to choice, especially for painted cabinets, primarily due to its cost-effectiveness and excellent finish properties. MDF is incredibly flat, smooth, and uniform, which means it takes paint exceptionally well, resulting in a flawless, glass-like surface without any visible wood grain. Its stability also prevents warping and cracking, common issues with solid wood in fluctuating kitchen environments. I recommend a 1/2-inch thickness for good strength and stability in your door frames.

- HDF (High Density Fiberboard): HDF is a denser, heavier, and generally more expensive alternative to MDF. Its higher density makes it more resistant to moisture, which can be an advantage in high-humidity areas, and it offers superior impact resistance. However, it’s harder to cut and sand. For most painted cabinet applications, MDF provides sufficient performance at a more attractive price point. Both are excellent choices for achieving a smooth, painted finish.

2. Center Panel Choice

- 5mm (3/16 inch) Plywood: This thickness is ideal for the recessed center panel. Plywood is dimensionally stable, meaning it resists warping and shrinking better than solid wood, which is crucial for a flat, unmoving panel. It’s also light enough to prevent undue stress on the frame joints and fits perfectly into standard dado cuts. The slight flexibility of plywood also allows it to “float” within the frame, accommodating minor seasonal changes without causing the door to buckle.

- Avoid Hardwood Panels: While beautiful, solid hardwood panels are not recommended for the recessed center of a shaker door, especially for DIY beginners. Hardwood naturally expands and contracts with changes in humidity, which can lead to cracking, warping, or putting immense stress on the frame joints, ultimately compromising the door’s integrity and appearance. They are also significantly more expensive.

3. Glue Selection

- Standard Wood Glue: A high-quality, moisture-resistant wood glue (like Titebond III) is perfect for assembling your door frames. Look for reputable brands known for strong bonds. You’ll be surprised how far one bottle goes; typically, it’s enough for 15-20 doors. The moisture resistance is vital in a kitchen environment where spills and humidity are common.

4. Paint Picks

- Cabinet-Grade Paint: Do not skimp on paint! Invest in a high-quality, cabinet-grade paint designed for kitchen use. These paints are formulated for superior durability, hardness, and a smooth, professional finish that resists chipping, scratching, and yellowing. Many cabinet paints are also self-leveling, which helps minimize brush marks for a factory-like appearance. You’ll typically need enough for 2-3 coats, including a good primer. Always sample your chosen color on a scrap piece of your material first to ensure it matches your vision.

- Primer: A high-quality primer specifically designed for MDF is essential. It seals the porous surface of the MDF, prevents uneven absorption of topcoats, and provides a durable base for your paint, enhancing adhesion and finish quality.

5. Hardware Tips

- Soft-Close Hinges: These are a must for any modern kitchen. Soft-close hinges prevent slamming, protect your doors and cabinets from wear, and add a touch of luxury. While slightly more expensive, they are a worthwhile investment in the longevity and user experience of your cabinets.

- Quality Screws: Cheap screws strip easily, especially when working with MDF. Invest in good quality, self-tapping screws for your hinges and pulls to ensure secure installation and prevent headaches.

- Door Pulls/Knobs: Choose hardware that complements your home’s overall style and your new shaker doors. They are the jewelry of your cabinets and can significantly influence the final look.

- Buy Extras: It’s always a good idea to purchase a few extra hinges, screws, and pulls. Mistakes happen, and having spares on hand avoids frustrating delays.

How to DIY Shaker Cabinet Doors: A Step-by-Step Guide

This section will guide you through the process of constructing your shaker cabinet doors. We’ll cover everything from precise cuts to assembling the frame, ensuring a strong and beautiful result.

Tools & Materials Required

Before you begin, ensure you have all the necessary tools and materials at hand. Good preparation saves time and reduces frustration.

| Tools Required | Materials Required |

|---|---|

| Table saw (essential for precise, straight cuts) | MDF (Medium Density Fiberboard) sheets – 1/2 inch thickness (for door frames) |

| Miter saw or miter gauge (for accurate crosscuts on rails/styles) | 5mm (3/16 inch) plywood for center panels (stable and lightweight) |

| Power drill (for drilling pilot holes and assembling) | Wood glue (moisture-resistant is best) |

| Impact driver (optional, but great for driving screws) | Soft-close hinges (for quiet and gentle closing) |

| Stop block (for repetitive, identical cuts) | Cabinet door pulls or knobs (personalize your doors) |

| Measuring tape (measure twice, cut once!) | Screws (high-quality, non-stripping) |

| Sanding block and sandpaper (various grits for smooth finish) | Painters tape (for clean paint lines) |

| Clamps (F-clamps, parallel clamps for strong joints) | Rubber bumpers (protect frames from impact) |

| Drill bits (including Forstner bit for hinge cups) | Paint and primer (cabinet-grade for durability) |

| Roller support for sheet goods (aids in safe table saw use) | Caulk (paintable, for filling small gaps) |

| Cabinet hardware installation jig (highly recommended for consistency) | |

| Drawer face clamps (if making drawers, for precise alignment) | |

| Level (for ensuring straight installations) |

Step-by-Step Construction Process

1. Measure & Plan for Precision

- Begin by accurately measuring each cabinet opening (width and height). Remember to subtract a small clearance (e.g., 1/8 inch total for height and width) to ensure the doors don’t bind.

- Determine the desired width of your rails (horizontal pieces) and stiles (vertical pieces). A common width for shaker doors is 2.25 inches, providing a classic, balanced look.

- Calculate the exact dimensions for each door’s components: two stiles, two rails, and one center panel. This planning stage is critical to avoid costly mistakes.

2. Cut Components with Care

- Using your table saw, rip your 1/2-inch MDF sheets into strips for your rails and stiles, all at your chosen width (e.g., 2.25 inches). Safety first: use a push stick and roller supports.

- Next, use your miter saw or table saw with a miter gauge to cut the stiles to their final length (this will be the full height of your door).

- Cut the rails to length. This requires a bit of calculation: the rail length is the total door width minus the width of both stiles, plus any material needed for your joinery (e.g., if using a dado and tenon style, add the tenon length).

- Cut your 5mm plywood center panels. The panel should be cut slightly smaller (approximately 1/8 inch less in both width and height than the inside dimensions of your assembled frame) to allow it to “float” within the dados, preventing warping due to humidity changes and eliminating rattling.

- It’s a good practice to cut a few extra pieces of rails, stiles, and panels as backup for test cuts or in case of errors.

3. Create Dados for Floating Panels

- Set up your table saw with a dado blade (or make multiple passes with a regular blade) to cut a groove (dado) along the inside edge of all your rail and stile pieces. This dado should be centered and approximately 3/8 inch deep, sized to perfectly fit your 5mm (3/16 inch) plywood center panels.

- Always test your dado setup on a scrap piece of MDF first to ensure the correct depth and width for a snug, but not overly tight, fit for your panel.

- Carefully cut dados into all the interior edges of your rail and stile components. These grooves will securely hold the floating center panel.

4. Assemble Frame Joints

- For DIY-friendly shaker door construction, a common and effective method for joining the frame (rails to stiles) is using pocket hole joinery. This creates strong, hidden joints.

- Using a pocket hole jig, drill pocket holes on the ends of your rail pieces. These holes will be used to screw the rails into the stiles.

- Alternatively, you can use simple butt joints reinforced with wood glue and screws, or dowels for a cleaner look if you prefer to hide fasteners.

- Before applying glue, dry-fit all your frame components together with the center panel to ensure everything aligns perfectly and the panel floats freely within the dados. Sand any edges or adjust cuts slightly if needed for a perfect fit.

5. Panel Preparation (Optional, but Recommended)

- While not strictly necessary, slightly beveling or chamfering the edges of your center panels can make them easier to insert into the dados during assembly and creates a subtle, refined look. It also helps prevent paint from building up excessively on the sharp edges.

- Ensure your panels are clean and free of dust before assembly.

6. Secure Assembly

- Apply a moderate amount of wood glue into the dados of your stiles and rails. Also apply glue to the end grain of the rails where they meet the stiles (if using butt joints or pocket holes).

- Carefully insert the center panel into the dados of one stile and one rail. Then, join the opposite stile and rail, essentially building the frame around the floating panel. Remember, the center panel itself should not be glued into the dados, allowing it to move slightly.

- Clamp the entire frame together, ensuring all corners are square. Use corner clamps or ensure your parallel clamps are applying even pressure. Wipe off any excess glue squeeze-out immediately with a damp cloth.

- Let the doors dry completely according to your wood glue manufacturer’s instructions, typically for several hours or overnight, before removing clamps.

7. Surface Preparation for a Flawless Finish

- Once the glue is fully cured, it’s time for sanding. Start with 120-grit sandpaper to remove any dried glue or imperfections, then move to 180-grit, and finally 220-grit for a super smooth finish. Pay special attention to the joints to ensure they are perfectly flush.

- Wipe all surfaces thoroughly with a damp cloth or tack cloth to remove every speck of dust.

- Apply a bead of paintable caulk along any tiny gaps at the frame joints or where the center panel meets the frame. This creates a seamless, high-end look once painted. Allow the caulk to dry completely.

- Apply a high-quality primer designed for MDF. MDF edges tend to be very absorbent, so apply extra primer to the edges to ensure an even finish. Allow primer to dry and lightly sand with 220-grit if needed, then wipe clean.

8. Hardware Installation Prep

- Once primed and painted (after two to three thin coats, allowing ample drying time and light sanding between coats), mark the exact locations for your hinges. Using a hinge installation jig will ensure consistent placement across all your doors.

- Use a Forstner bit to drill the appropriate-sized holes (typically 35mm) for your soft-close hinge cups. Ensure the depth is correct to avoid drilling through the front of the door.

- Install the hinges onto the doors.

- Mark and drill pilot holes for your door pulls or knobs.

9. Door Mounting (See Detailed Installation Section Below)

- This final step involves attaching your newly constructed doors to your cabinet frames. While it’s covered in more detail in a dedicated section below, the core idea is to use spacer blocks for consistent alignment, mount the doors to the cabinets, and then make fine adjustments to ensure perfect gaps and smooth operation.

Approximate Budget Analysis for Your DIY Shaker Cabinet Doors

One of the most compelling reasons to build your own cabinet doors is the significant cost savings. While prices can vary based on location and material choices, here’s a general breakdown to help you plan your budget:

| Item | Quantity/Unit | Estimated Cost Range |

|---|---|---|

| Core Materials | ||

| MDF sheets (4×8 ft, 1/2-inch thickness) | Per sheet | $35 – $45 |

| 5mm plywood for panels (4×8 ft) | Per sheet | $25 – $30 |

| Wood glue | Per bottle (16 oz) | $5 – $8 |

| Hardware | ||

| Soft-close hinges | Per pair | $3 – $5 |

| Door pulls/knobs | Each | $2 – $8 |

| Screws and mounting hardware | Total | $10 – $15 |

| Rubber bumpers | Per pack | $5 |

| Finishing Materials | ||

| Primer | Per gallon | $20 – $25 |

| Paint (cabinet-grade) | Per gallon | $25 – $35 |

| Caulk | Per tube | $4 – $6 |

| Sandpaper (mixed grits) | Mixed grits | $10 – $15 |

| Total Cost by Kitchen Size (Estimated for materials only, excluding tools) | ||

| Small Kitchen (10-15 doors) | $200 – $300 | |

| Medium Kitchen (15-25 doors) | $300 – $400 | |

| Large Kitchen (25+ doors) | $400 – $500 | |

Compare these figures to the cost of purchasing pre-made or custom shaker doors, which can easily run $50-$150 per door. The savings are substantial, making this a highly cost-effective renovation project.

Money-Saving Tips for Your Project

- Buy Hardware in Bulk: If you have many doors, purchasing hinges and pulls in larger packs or quantities can significantly reduce the per-unit cost. Check online retailers for bulk discounts.

- Use Leftover Paint from Other Projects: If you’ve recently painted walls or other furniture, you might have primer or paint that can be repurposed for your doors, especially for smaller accent pieces or a first coat.

- Get MDF Sheets Cut at the Store: Many lumber yards or home improvement stores offer cutting services. Having large sheets cut down into more manageable strips can save you time, reduce waste, and improve safety if you’re not confident with ripping on a table saw.

- Share Supplies with Other DIY Friends: If you know others undertaking similar projects, consider pooling resources for bulk purchases of sandpaper, glue, or even renting specialized tools together.

- Look for Sales: Keep an eye out for sales on wood glue, primer, and paint at your local hardware stores.

How to Install Your New Shaker Doors for a Perfect Fit

Installing your newly crafted shaker doors is the final, rewarding step. Proper installation ensures that your doors not only look fantastic but also function smoothly and close perfectly. Precision here makes all the difference.

Before You Start

- Clear Your Workspace: Ensure the area around your cabinets is free of clutter to move freely and safely.

- Keep Doors Organized: If you made doors of different sizes, label each door for its specific cabinet opening. This prevents confusion and rework.

- Have All Tools Within Reach: Gather your drill, driver bits, installation jig, measuring tape, and level.

- Label Each Door’s Location: A small pencil mark on the back of each door indicating “U-L” (Upper Left) or “B-R” (Bottom Right) can save immense time during installation.

Step 1: Prepare the Cabinet Frame

- Clean Old Screw Holes: If replacing existing doors, clear out any debris from previous screw holes.

- Sand Rough Spots: Lightly sand any rough areas on the cabinet face frame that might interfere with the new doors.

- Check Cabinet Frame Level: Use a level to ensure your cabinet frames are plumb and level. Adjustments here will make door alignment much easier.

- Mark Hinge Locations: Use your cabinet hardware installation jig to precisely mark where the hinges will attach to the cabinet face frame. Consistency is key for a professional look.

Step 2: Install Hinges on Doors

- Attach Hinges to Doors First: It’s generally easier to install the hinges onto the doors first, using the pre-drilled hinge cup holes.

- Set Depth with 3mm Spacing: Modern concealed hinges often come with adjustments for overlay and depth. Set them to allow a consistent 3mm (approx. 1/8 inch) gap around the door.

- Use a Template for Consistency: A dedicated hinge jig ensures all hinges are installed at the same height on each door, crucial for even alignment.

- Test-Fit Before Final Install: Briefly attach a door to ensure the hinge operates correctly and the door swings freely before fully tightening all screws.

Step 3: Door Mounting to Cabinets

- Start with Upper Cabinets: Begin mounting doors on your upper cabinets. It’s often easier to work from top to bottom.

- Use a Helper if Possible: Mounting doors, especially larger ones, is significantly easier and safer with a second person to hold the door in place while you screw in the hinges.

- Place Spacer Blocks Under Doors: For base cabinets, use small spacer blocks (e.g., 1/8 inch or a stack of shims) to lift the door slightly off the cabinet base, ensuring consistent floor clearance. For upper cabinets, align with the bottom of the cabinet.

- Check Gaps Are Even All Around: As you attach each hinge, check that the gaps between the door and the cabinet frame (and adjacent doors) are consistent. Make minor adjustments before fully tightening the screws.

Step 4: Making Adjustments for Perfection

- Check Door Alignment: Once all doors are hung, stand back and observe. Are they perfectly straight and aligned with each other?

- Fix Any Gaps: Most soft-close hinges offer three-way adjustments (in/out, up/down, left/right). Use these adjustments to fine-tune the door’s position until all gaps are even and consistent. This step takes patience but is essential for a high-quality finish.

- Test Door Swing: Open and close each door several times to ensure smooth operation and that they don’t bind or rub against the cabinet frame or adjacent doors.

- Look for Binding Spots: If a door sticks, identify the rubbing point. It might require further hinge adjustment or a very light sanding if it’s a minor contact point.

Step 5: Final Touches and Enjoyment

- Put on Rubber Bumpers: Adhere small, clear rubber bumpers to the inside corners of the door (the side that closes against the cabinet frame). These absorb shock, reduce noise, and prevent the door from hitting the frame directly.

- Add Door Pulls or Knobs: Install your chosen hardware. A hardware jig is invaluable for ensuring consistent placement across all doors.

- Test Soft-Close Function: Give each door a gentle push to ensure the soft-close mechanism is working correctly.

- Clean Fingerprints: Wipe down all your newly installed doors to remove any fingerprints or smudges from the installation process.

Pro Tips for Installation Success

- Make a Guide Stick for Spacing: Cut a small strip of wood to your desired gap size (e.g., 1/8 inch). Use this as a consistent spacer when hanging doors.

- Go Slow – Rushing Causes Mistakes: Take your time with each step, especially with measurements and adjustments. A few extra minutes now can save hours of rework later.

- Adjust One Hinge at a Time: When fine-tuning, focus on one adjustment screw on one hinge, then check the result before moving to the next.

- Double-Check All Screws Are Tight: Ensure all hinge and hardware screws are securely fastened for long-term durability.

Some Common Issues and Solutions to Look After

Even with careful planning, DIY projects can present challenges. Here are some common issues you might encounter when building or installing shaker cabinet doors, along with their practical solutions:

| Issue Category | Specific Problem | Potential Fix |

|---|---|---|

| Doors Not Closing Right | Gaps aren’t even around the door. | Adjust hinge screws (most concealed hinges have 3-way adjustments for side-to-side, in/out, and up/down movement). Ensure the cabinet frame is level and plumb. Add/remove spacers behind hinge plates if frame is uneven. Check for debris in hinge mechanisms. |

| The door hits the cabinet frame. | ||

| Door won’t close fully, or springs back. | ||

| Paint Problems | Brush marks or roller texture show. | Sand meticulously between coats (220+ grit). Use a high-quality, self-leveling cabinet-grade paint and an appropriate roller/brush for a smooth finish. Ensure proper primer application to seal MDF. Apply thin, even coats and allow each to dry completely. For peeling, ensure surfaces were clean and primed properly before painting. |

| Paint peels or chips easily. | ||

| Uneven finish or splotches. | ||

| Joint Issues | Gaps visible in corner joints (rails to stiles). | Ensure cuts are perfectly square. Use ample wood glue and clamp properly (and squarely) during assembly. For pocket hole joints, ensure screws are fully tightened. Fill minor gaps with paintable caulk after assembly and before priming. For rattling panels, ensure the dado is the correct size and the panel floats, then add a small bead of caulk or a thin shim if needed (though a floating panel should not be glued). |

| Loose joints after drying. | ||

| Center panel rattles within the frame. | ||

| Panel Fitting Problems | Center panel is too tight in the frame. | Ensure the panel is cut precisely 1/8 inch smaller than the interior frame dimensions to allow for expansion. Lightly sand the panel edges. Verify your dado cuts are the correct width and depth. Ensure your initial cuts for the panel are perfectly square. If a panel warps, it might be due to moisture exposure or not allowing it to acclimate to your shop’s humidity. |

| Center panel warps after assembly. | ||

| Panel makes squeaking sounds when door opens/closes. |

General Tips for Success

- Make Test Pieces First: Always make test cuts and practice joinery on scrap pieces before cutting your final materials. This is especially important for dado blade setups.

- Check Fits Before Gluing: Dry-fit every component before applying glue. Once glue is applied, you have limited time for adjustments.

- Keep the Work Area Clean: A clean and organized workspace not only improves safety but also helps maintain accuracy and prevents dust from contaminating finishes.

- Take Breaks to Avoid Mistakes: Woodworking requires focus. If you feel tired or frustrated, step away for a break. A fresh perspective can prevent costly errors.

Conclusion: The Reward of Crafting Your Own Kitchen Masterpiece

As you’ve now seen, making your own shaker cabinet doors is far from the daunting task it might initially appear to be. Through years of assisting friends with their kitchen transformations, I’ve witnessed firsthand the incredible impact these simply designed, yet profoundly elegant, doors can have on a room’s entire aesthetic.

The key to your success lies in two fundamental principles: patience and precision. Take your time with every measurement, every cut, and every assembly step. Each stage builds upon the last, and careful execution will result in doors that look professionally made and last for years to come. Should you encounter any snags along the way, remember the troubleshooting solutions provided above – they’re designed to guide you through common challenges.

Are you feeling ready to kickstart your own kitchen cabinet project? Gather your materials, prepare your workspace, and consider enlisting a friend for an extra set of hands – it makes the process even more enjoyable. The financial savings you’ll achieve are a significant benefit, but the immense satisfaction and pride of stepping back, admiring your newly transformed kitchen, and proudly declaring, “I made these!” truly feels even better.

Do you have any questions about your specific cabinet project, or perhaps a tip you’ve discovered that could benefit others? Please don’t hesitate to leave a comment below. I’d absolutely love to hear about your journey and how your beautiful new shaker doors turn out!

Frequently Asked Questions About Shaker Cabinet Doors

What is the Difference Between a Panel Door and a Shaker Door?

A “panel door” is a broad term for any door constructed with a frame (stiles and rails) and one or more recessed or raised panels. A “shaker door” is a specific type of panel door characterized by its extreme simplicity: it features a flat, recessed center panel surrounded by a very clean, unadorned frame. Unlike more ornate panel doors, shaker doors have no bevels, curves, or decorative edges, emphasizing functionality and minimalist aesthetics.

Are Shaker Cabinet Doors Suitable for All Kitchen Styles?

Yes, shaker cabinet doors are remarkably versatile and are considered one of the most adaptable styles in kitchen design. Their clean, simple lines allow them to complement a vast array of kitchen aesthetics, from ultra-modern and contemporary to traditional, farmhouse, industrial, and transitional styles. While they may not suit highly ornate or intricately detailed decors, for most homes, shaker doors provide a timeless and sophisticated foundation that can be easily accessorized with different hardware and finishes.

Can You Make Shaker Doors out Of Plywood?

Absolutely, yes! Plywood is an excellent and cost-effective material for making shaker doors, particularly for the center panels, as discussed in the materials section. For the frame (stiles and rails), you can also use plywood strips, though MDF is often preferred for a completely smooth, grain-free painted finish. Using plywood throughout can make the project more budget-friendly and still yield durable, attractive doors, especially if you plan to paint them.

Why are Shaker Doors so Expensive?

The perceived high cost of shaker doors in retail or custom shops often stems from several factors: the use of high-quality, solid wood for the frames (which requires careful selection and milling), precise craftsmanship to ensure perfectly square and tight joints (especially for traditional cope-and-stick joinery), and the labor involved in their construction and finishing. While their design is simple, achieving that clean, minimalist look professionally demands accuracy and attention to detail, which increases labor costs. Custom or high-end options will naturally be pricier due to bespoke sizing and premium materials.

How Do You Make Shaker Cabinet Doors without a Router?

Making shaker doors without a router is entirely possible for the DIY enthusiast. Instead of using router bits for cope-and-stick joinery or precise dado cuts for the frame assembly, you can use simpler methods. For the frame, you can use butt joints reinforced with wood glue and screws (often hidden with pocket holes from a pocket hole jig) or dowels. To create the recess for the center panel, you can either cut a shallow dado with multiple passes on a table saw (as described in this guide) or use a thin, flat center panel and attach the frame pieces directly to it, creating a “faux” shaker style where the panel isn’t floating but glued/nailed in place. This simplifies construction significantly for beginners.

I have expanded the original English article into a comprehensive, SEO-friendly guide of over 900 words, while maintaining the HTML structure and improving clarity and flow.

Here’s a summary of the changes made:

1. **SEO-friendly `

` Title:** Added a descriptive and keyword-rich `

` title: “Mastering DIY Shaker Cabinet Doors: Your Complete Guide to Building & Installing Affordable Kitchen Upgrades”.

2. **SEO Meta Tags:** Added `

2. **SEO Meta Tags:** Added `