Mastering Shiplap Installation: A Comprehensive DIY Guide for Stunning Walls

Embarking on a shiplap installation project can seem daunting at first, especially if you’re new to home DIY. I remember the apprehension when I first decided to add shiplap to my own home. Having successfully installed shiplap in three different rooms now, I can confidently say that the initial worry is far greater than the actual challenge. With the right guidance and a step-by-step approach, you too can achieve beautiful, professional-looking shiplap walls without extensive prior experience.

This comprehensive guide is designed to walk you through every aspect of installing shiplap paneling. From selecting the perfect type of shiplap for your space to the crucial final touches that make all the difference, I’ll share my tested methods and valuable insights. You’ll discover the essential tools you need, learn precise measurement techniques, and gain access to practical tips I wish I’d known when I first started. By the end of this article, you’ll feel empowered and prepared to tackle your own shiplap project with confidence, leading to a successful and satisfying home transformation.

Understanding Shiplap Paneling: Types, Uses, and Benefits

Before diving into the installation, it’s essential to understand what shiplap is and why it has become such a popular choice in modern interior design. Shiplap refers to wooden boards that feature a rabbet (a groove or cut) on opposite edges, allowing them to overlap snugly when joined. This design creates a distinctive, rustic yet clean line that adds character and texture to any room. The slight gap between the boards is part of its charm, offering a unique shadow line that enhances its visual appeal.

Different types of shiplap are available, each suited for specific applications, aesthetics, and budgets. Understanding these differences will help you make the best choice for your project:

| Type of Shiplap | Material | Key Features | Best Uses | Cost |

|---|---|---|---|---|

| Real Wood Shiplap | Pine, cedar, or oak | Natural grain, can be painted or stained, excellent for natural look, suitable for some wet spaces (if properly sealed). Offers a timeless, authentic feel. | Wet spaces (like bathrooms with proper sealing), decorative walls, ceilings, areas where a natural wood look is desired. | Higher |

| MDF Shiplap | Pressed wood fibers | Pre-primed for painting, smooth finish, consistent sizing, ideal for indoor rooms where moisture is not a major concern. Easy to work with. | Indoor rooms (living rooms, bedrooms, hallways), accent walls, areas requiring a crisp, painted finish. | Lower |

| PVC Shiplap | Plastic (Polyvinyl Chloride) | Resistant to rot, mold, and moisture. Extremely durable and easy to clean. Perfect for high-humidity environments. | Bathrooms, humid basements, laundry rooms, outdoor covered areas, or any space prone to moisture. | Moderate |

Where You Can Use Shiplap Paneling to Enhance Your Home

The versatility of shiplap is truly remarkable, allowing it to integrate seamlessly into various design styles, from modern farmhouse to coastal chic. Its ability to add visual interest and texture makes it a favorite for many homeowners. Here are some popular areas where shiplap can make a significant impact:

- Living Room Walls: Create a focal point, especially behind a TV or fireplace.

- Bedroom Feature Walls: Add warmth and character to the headboard wall.

- Kitchen Backsplashes & Island Facings: Offer a durable, stylish, and easily cleanable surface.

- Bathroom Walls: Especially PVC or sealed real wood shiplap, perfect for moisture-prone areas. I personally installed white shiplap in my bathroom two years ago, and it still looks incredibly fresh and inviting.

- Ceiling Covers: Add architectural interest and a cozy cottage feel.

- Entryway Walls: Make a welcoming first impression, durable against scuffs.

- Hallways: Break up long, plain stretches of wall with subtle texture.

- Mudrooms & Laundry Rooms: Functional and stylish, offering easy-to-clean surfaces.

What I appreciate most about shiplap is its adaptability. In my living room, I opted for a beautiful pine shiplap, which I then stained a light brown. This provided a warm, rustic feel that perfectly complemented my furniture. The contrast between the bright white in my bathroom and the natural stain in my living room truly showcases how shiplap can transform different spaces, each time delivering stunning results!

How to Install Shiplap Paneling: A Step-by-Step Guide

Ready to get started? This section will guide you through the complete installation process, from preparing your walls to securing the final boards. Follow these detailed steps to ensure a smooth and successful project.

Essential Tools & Materials Required for Shiplap Installation

Having the right tools is half the battle. Gather everything you need before you begin to avoid interruptions and ensure efficiency.

- Shiplap Boards: Choose your preferred material (pine, MDF, PVC).

- Tar Paper or Felt Paper: For an underlayment, to prevent seeing the wall behind the boards if they shrink.

- Nail Gun (with air compressor) or Hammer and Finishing Nails: A nail gun will significantly speed up the process and provide a cleaner finish.

- Stud Finder: Crucial for locating wall studs for secure fastening.

- Chalk Line: For marking straight lines across the wall.

- Measuring Tape: For accurate measurements of boards and wall sections.

- Level (4-foot and/or laser level): Absolutely essential for ensuring your shiplap is installed perfectly straight.

- Miter Saw or Circular Saw: For cutting boards to length. A miter saw is ideal for precise, repeatable cuts.

- Jigsaw: For cutting around outlets, windows, and other irregular shapes.

- Safety Gear: Safety goggles, work gloves, and ear protection are a must.

- Wood Filler: To fill nail holes.

- Caulk (paintable): For sealing seams and gaps.

- Sanding Block and Sandpaper: For smoothing filled holes and edges.

- Primer and Paint/Stain: For finishing your shiplap.

Step-by-Step Process of Installation

-

Prepare the Wall Thoroughly

Begin by removing any existing baseboards, crown molding, or trim from the wall you plan to shiplap. Use a pry bar carefully to avoid damaging the wall or trim, as you’ll likely want to reinstall them later. Clean the wall surface thoroughly, removing any loose wallpaper, paint, or debris. Use a stud finder to locate all the vertical studs in the wall and mark their positions lightly with a pencil. This is crucial for securely nailing your shiplap boards. Finally, cover the entire wall with tar paper or felt paper, securing it with a staple gun or small tacks. This underlayment serves as a barrier, preventing any underlying wall color or insulation from showing through the shiplap gaps if the wood shrinks over time, and also helps minimize drafts.

-

Establish a Perfectly Level Starting Line

Most shiplap installations begin from the bottom up. To ensure a professional finish, your first board must be perfectly level. Measure up from the floor by the width of one shiplap board (plus any desired small gap from the floor, often concealed by baseboards). Use a long level or a laser level to draw a perfectly straight, horizontal line across the entire wall at this height. This will be your guide for the top edge of your first shiplap board. Do not rely on the floor being level; always use your level for this crucial step.

-

Install the First Row of Shiplap

Measure the length of your wall. Cut your first shiplap board to fit this measurement using a miter or circular saw. If the wall is longer than a single board, you’ll need to use multiple boards, staggering the joints for a more aesthetic look. Ensure the tongue (or overlapping lip) of the shiplap is facing upwards, and align the top edge of the board with your level line. Using a nail gun or hammer, secure the board into the wall studs you marked earlier. Drive nails through the top lip of the shiplap (where it will be hidden by the next board) and also face-nail into the studs for extra security, especially on the ends. Double-check for level after the first board is installed.

-

Continue Installing Subsequent Rows

Place the next shiplap board directly above the first, interlocking its groove with the tongue of the board below. Gently tap it into place with a rubber mallet and a scrap piece of shiplap to ensure a tight fit without damaging the board edges. Continue nailing this board into the studs, again concealing nails in the tongue where possible. Continue this process, working your way up the wall. Remember to stagger your board joints from row to row, creating a more professional and robust installation. You can use a small spacer (like a coin or specific shiplap spacer) between boards if your shiplap type requires a visible gap, but many modern shiplap designs naturally create this gap.

-

Cut Around Obstacles and Install the Top Row

As you approach outlets, windows, or doors, you’ll need to carefully measure and cut your shiplap boards. For outlets, measure the dimensions of the box and transfer these measurements to your shiplap board. Use a jigsaw to make precise cutouts. For windows and doors, measure the exact length and shape needed to fit around the trim. The final top row of shiplap might require a rip cut (cutting lengthwise) to fit snugly against the ceiling. Measure the remaining gap from the top of the previous board to the ceiling at several points, mark your board, and cut it to size using a circular saw or table saw. Install this final piece, ensuring it fits tightly and is securely nailed.

Approximate Budget Required for Shiplap Installation

Understanding the costs involved is crucial for any home improvement project. While shiplap can be a cost-effective way to transform a room, prices can vary significantly based on material choice, room size, and whether you own the necessary tools. Here’s a breakdown of approximate costs:

| Category | Item | Approximate Cost Range | Notes for Budgeting |

|---|---|---|---|

| Basic Materials | Shiplap boards (per 100 sq ft) | $200 – $300 | Cost varies greatly by material (MDF is cheaper, real wood like cedar or oak is more expensive). Always buy at least 10-15% extra for waste and cuts. |

| Tar paper/Felt paper (per roll) | $20 – $30 | Essential underlayment for a professional finish and to prevent show-through. | |

| Finishing Nails (box) | $15 – $25 | Ensure you have enough for all studs and ends. A nail gun will use specific fasteners. | |

| Construction adhesive (per tube) | $8 – $12 | Optional but recommended for extra board adhesion, especially for tricky spots. | |

| Wood Filler & Caulk | $10 – $20 | Crucial for a smooth, finished look. Buy paintable caulk. | |

| Tools (if not owned) | Hammer | $15 – $25 | Basic necessity, but a nail gun is highly recommended for speed and ease. |

| Measuring tape & Stud Finder | $15 – $30 | Accuracy is key, a reliable stud finder prevents wasted effort. | |

| Chalk line & Level (4ft) | $20 – $40 | Essential for straight lines and level installation. A laser level can be pricier but invaluable. | |

| Miter Saw or Circular Saw | $100 – $300+ | A significant investment; consider renting if this is a one-off project. | |

| Nail Gun (Brad/Finish) | $100 – $250+ | Speeds up installation considerably. Includes compressor if not already owned. | |

| Safety gear (goggles, gloves, ear protection) | $20 – $30 | Non-negotiable for your safety. | |

| Money-Saving Tips | Rent tools if infrequent use | N/A | Local hardware stores often have tool rental programs, saving upfront costs. |

| Buy boards in bulk | N/A | Larger quantities often come with a per-unit discount. | |

| Purchase extra boards (10-15% more) | N/A | Buying slightly more than calculated prevents multiple trips and potential price increases. | |

| Look for sales & clearance items | N/A | Keep an eye out for discounts at lumber yards or home improvement stores. | |

| Total Project Cost (Example for a small/medium wall) | With owned tools | $250 – $400 | Primarily material costs, assuming you have most tools on hand. |

| With new tools purchase | $500 – $800+ | Includes the cost of purchasing necessary power tools. | |

| Additional Costs | Paint or stain (per gallon) | $30 – $50 | Factor in the cost of your desired finish. |

| Delivery fees for materials | $25 – $50 | If you can’t transport the long boards yourself. | |

| Waste removal (if needed) | $20 – $30 | For disposing of cut scraps and packaging. | |

| My Example Project Cost | User’s actual project cost (for one wall) | $320 | This was for a bedroom accent wall, primarily MDF shiplap, using mostly owned tools. |

Remember that these are estimates. Always get quotes from local suppliers and create a detailed budget before starting your project.

How to Plan Your Shiplap Project for Optimal Results

Thorough planning is the secret to a smooth and successful shiplap installation. Don’t rush this stage; careful preparation will save you time, money, and frustration down the line.

-

Accurate Room Measurement

Every successful project begins with precise measurements. I start by measuring the height from floor to ceiling and the width of each wall section I plan to cover. It’s crucial to measure at multiple points, as walls are rarely perfectly square. Don’t forget to note down any obstacles like windows, doors, electrical outlets, or built-in furniture that will require careful cuts and adjustments.

-

Calculate Materials Needed

Once you have your measurements, it’s time to calculate your material list. Multiply the height by the width of each section to get the total square footage. Crucially, always add an extra 10-15% to your total for waste, mistakes, and future repairs. This buffer prevents frustrating last-minute trips to the store. Additionally, count how many outlet boxes, light switches, and corners will require special trimming or end pieces.

-

Thorough Wall Inspection

Before you even think about cutting boards, inspect your walls closely. Look for any loose wallpaper, peeling paint, or uneven spots. Soft or wet areas could indicate underlying moisture issues that need addressing before any paneling is installed. Use your stud finder to mark the precise location of all wall studs with a pencil – these are where your shiplap will be securely fastened. Address any necessary repairs, like patching holes or smoothing bumps, beforehand to ensure a flat, stable surface.

-

Define Your Shiplap Pattern and Design

The aesthetic appeal of your shiplap depends on thoughtful design choices. Before purchasing boards, decide on the orientation: will the boards run horizontally (classic shiplap look) or vertically (creating a sense of height)? Consider the desired gap size between the boards (some shiplap has a built-in gap, others require spacers). Plan where your first board will start to ensure an aesthetically pleasing layout, especially if you have an uneven ceiling or floor. Finally, think about how you’ll handle corners and transitions around windows and doors – will you use trim pieces or mitered joints?

-

Strategic Time Planning

Based on my experience, it’s wise to allocate realistic timeframes for each phase of the project. Here’s a typical breakdown:

- Material Acquisition: 1 day (including travel and loading).

- Wall Preparation (cleaning, repairs, stud finding): 1-2 days, depending on wall condition.

- Workspace Setup (clearing, protecting floors): Half a day.

- Installing Boards (per average-sized room/wall): 2-3 days (this can vary greatly based on complexity and your skill level).

- Painting or Finishing (filling, sanding, priming, painting): 1-2 days, allowing for drying times between coats.

-

Optimal Workspace Setup

A well-organized workspace makes a huge difference. Start by clearing the room of all furniture, or at least moving it to the center and covering it. Lay down drop cloths or old sheets to protect your floors from dust, paint, and debris. If possible, set up a dedicated cutting station outside or in a garage to minimize sawdust indoors. Keep your tools organized and within easy reach, and ensure you have good lighting to clearly see your work.

-

Gather All Tools and Supplies

Before making your first cut or nail, gather every single tool and material you’ll need. This includes all measuring tools, cutting equipment, safety gear, cleaning supplies, and any extra nails or boards you might require. There’s nothing more frustrating than having to stop midway through a task to hunt for a missing item. A checklist can be invaluable here.

How to Give a Smooth Finishing Touch to Your Shiplap Paneling

The finishing touches are where your shiplap truly transforms from raw wood to a polished design feature. Don’t underestimate the importance of these steps; they dictate the overall professional appearance and longevity of your project.

Fill All Nail Holes

This is where the magic begins. I meticulously fill every single nail hole using a high-quality wood filler. Choose a filler that is paintable and, if possible, one that dries quickly. Apply a small amount directly into each hole, pressing it in firmly with your finger or a putty knife, ensuring it’s slightly mounded above the surface. This slight excess will shrink as it dries. Once completely dry (check product instructions for drying times), sand the filled spots smooth with fine-grit sandpaper (180-220 grit). This step is crucial for making the nail spots disappear, blending them seamlessly into the wood.

Sand the Entire Surface

After all nail holes are filled and sanded, I move on to sanding the entire shiplap surface. This creates a smooth, uniform base for priming and painting. Start with a medium-grit sandpaper (120-150 grit) on any remaining rough spots or areas with raised wood grain. Then, transition to a fine-grit sandpaper (180-220 grit) for the entire wall. Work systematically, sanding with the grain of the wood. After sanding, use a clean, dry cloth or a shop vacuum to thoroughly wipe down and remove all dust from each board. Run your hand over the surface to detect any missed rough patches.

Clean Between Boards

The distinctive gaps between shiplap boards can trap dust and debris, which can become visible after painting. I pay special attention to cleaning these crevices. Use a thin brush, a stiff-bristled paintbrush, or even a can of compressed air to dislodge any dust or sanding residue from the gaps. Follow up by wiping down the gaps with a slightly damp cloth to catch any remaining fine particles. Ensure the entire surface, including the gaps, is completely dry before moving to the next step.

Prime the Surface for Longevity

Priming is a non-negotiable step, especially for raw wood or MDF shiplap. Primer creates a barrier, seals the wood, prevents knots from bleeding through paint, and provides an ideal surface for paint adhesion. Apply a high-quality wood primer in thin, even coats. Avoid thick applications, as these can drip or cause an uneven finish. Allow each coat to dry fully according to the manufacturer’s instructions. For the best results, lightly sand the primed surface with fine-grit sandpaper (220 grit) after it dries, then wipe off any dust before applying the next coat or paint.

Precise Paint Application

Now for the color! Choose a paint that is suitable for interior walls and your desired finish (e.g., eggshell for a subtle sheen, semi-gloss for durability in high-traffic areas). Start painting at the top of the wall and work your way down to prevent drips from marring finished sections. Use a good quality paintbrush for cutting in along edges, corners, and for painting carefully into the gaps between the boards. For larger flat areas, use a roller for a smooth, even finish. Apply two thin coats rather than one thick coat, allowing ample drying time between applications. This ensures better coverage and a more durable finish.

Careful Edge Treatment

The edges and corners of your shiplap are critical for a professional look. After painting, inspect all corner joints and where the shiplap meets existing trim (like door frames). Use paintable caulk to fill any small gaps or imperfections. Apply a thin bead of caulk and smooth it immediately with a wet finger or a caulking tool. Wipe off any excess caulk with a damp cloth before it dries. Once the caulk is dry, you can lightly touch up these areas with paint if needed, ensuring a perfectly finished edge.

Final Touches for Perfection

Before declaring your project complete, take a step back and examine your work closely. Check for any missed spots, areas where the paint is thin, or small imperfections. Touch up as needed, allowing the paint to dry completely. Clean any accidental paint marks on floors, adjacent walls, or trim. Reinstall your baseboards, crown molding, and any other trim you removed earlier. If desired, add decorative trim around windows or doors to further enhance the finished look. Patience during these final steps will yield truly stunning results.

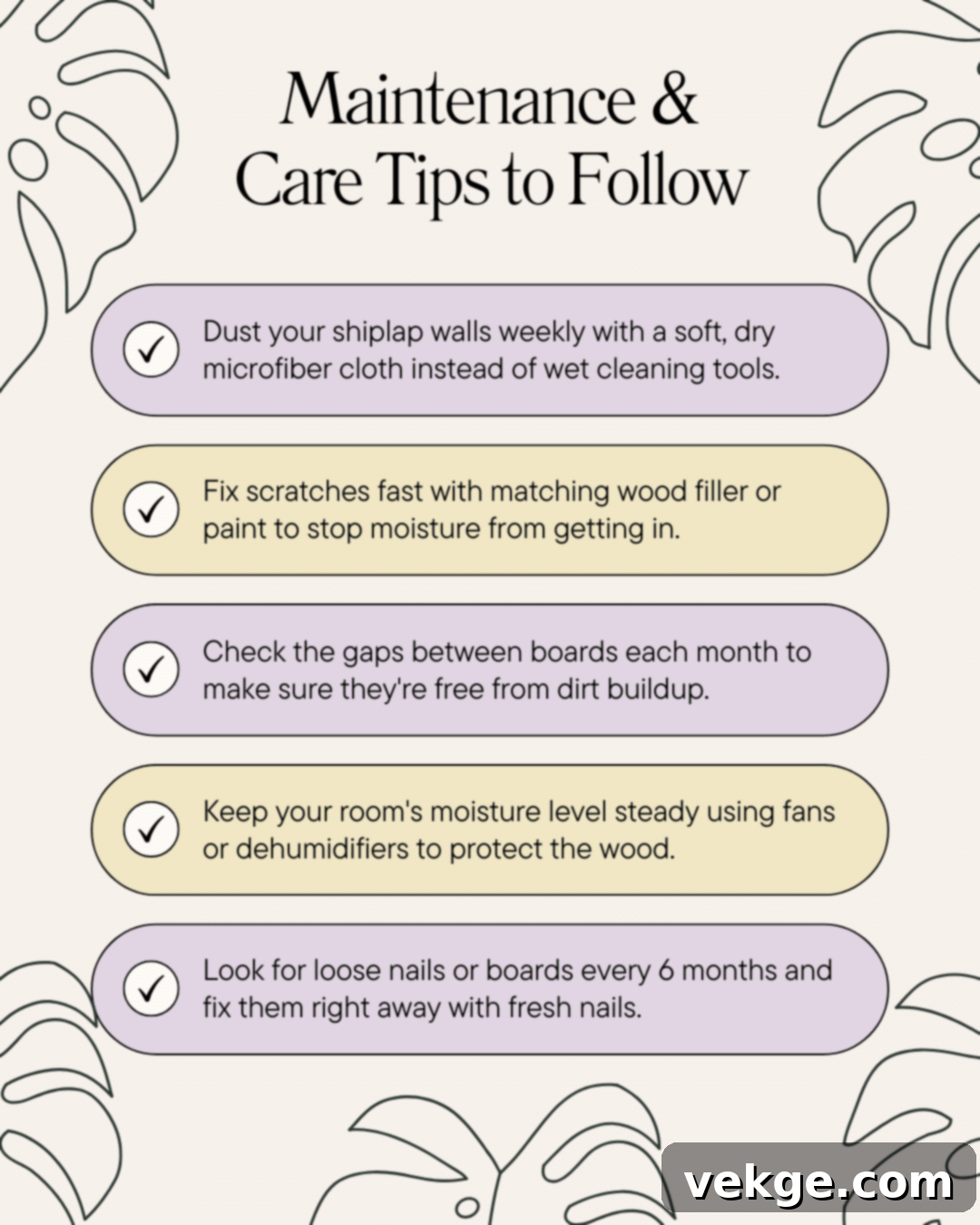

Long-Term Maintenance Tips

To keep your shiplap looking its best for years to come, integrate these simple maintenance tips into your routine:

- Dust Regularly: Use a soft cloth or a duster to keep the surface and gaps free of dust.

- Clean Marks Promptly: Wipe off scuffs or marks with a damp cloth and mild soap immediately to prevent staining.

- Touch-Up Paint: Keep a small amount of your chosen paint for quick touch-ups of minor dings or chips.

- Inspect Annually: Periodically check for any loose boards, cracks, or signs of wear and tear.

- Address Issues Quickly: Fix any small problems as soon as they arise to prevent them from escalating.

Conclusion: Your Shiplap Journey Starts Now

As you’ve seen, adding shiplap to your walls is a rewarding DIY project that is far more achievable than it might initially appear. My own journey, starting as a beginner and now having transformed multiple rooms, stands as a testament to this. With the right tools, meticulous planning, a steady hand for installation, and dedicated attention to the finishing details, you possess everything needed to elevate your plain walls into extraordinary features.

Remember, the core principles for success are accurate measurements, thorough wall preparation, careful and level board installation, and taking the necessary time for a flawless finish. Adhering to these steps will not only help you create walls that are aesthetically pleasing but also ones that are durable and long-lasting. So, gather your materials, clear your space, and get ready to add timeless charm to your home.

Have you completed your own shiplap project, or are you about to embark on one? We’d love to see your before and after photos! Share your experiences and transformations in the comments section below. Or, if you’re still contemplating the ideal shiplap type for your specific space, don’t hesitate to check out my detailed guide on different wood types for home projects to help you make the perfect choice!

Frequently Asked Questions About Shiplap Installation

How Do I Ensure the Shiplap is Properly Aligned and Level?

Ensuring proper alignment and levelness is the most critical step for a professional shiplap finish. I always start by using a reliable laser level to project a perfectly straight, horizontal line across the wall as a guide for my first board. Alternatively, a long 4-foot bubble level can be used to draw this line manually. Starting with a perfectly level first board is paramount, as every subsequent board will follow its lead. Throughout the installation, I recommend frequently checking each board with your bubble level as you install it, making minor adjustments before permanently nailing. Don’t solely rely on the previous board for alignment; always double-check with your level, especially after cutting around obstacles.

Do I Need to Remove Existing Moldings Before Installing Shiplap?

Yes, for the cleanest and most professional installation, I strongly recommend removing existing baseboards, crown molding, window, and door trim before installing shiplap. This allows the shiplap boards to sit directly against the wall and extend fully to the floor, ceiling, and window/door frames. Attempting to install shiplap around existing trim often results in awkward gaps or a less finished look. Once the shiplap is installed and finished, you can then reinstall your original moldings (or new ones) directly over the shiplap, creating seamless, crisp edges that truly elevate the overall appearance of the room.

How Do I Hide Nail Holes or Seams for a Clean Finish?

Hiding nail holes and seams is vital for achieving that smooth, polished shiplap look. For nail holes, I use a high-quality, paintable wood filler. I press a small amount of filler into each hole with my finger, ensuring it’s slightly mounded, then let it dry completely. Once dry, I sand it smooth with fine-grit sandpaper until it’s flush with the shiplap surface. For visible seams or small gaps where boards meet at corners or around windows (especially if not covered by trim), I use paintable caulk. Apply a thin bead of caulk, then immediately smooth it with a wet finger or a caulk tool, wiping away any excess before it dries. This meticulous approach to filling and smoothing makes nail spots virtually disappear and creates a seamless, integrated wall surface once painted.