Ultimate Guide to Deck Lumber Sizes: Nominal vs. Actual Dimensions for a Safe and Strong Build

Are you planning to build a new deck or renovate an existing one? If so, understanding lumber sizes is one of the most crucial steps. Different lumber dimensions are essential for creating a safe, stable, and long-lasting structure, from foundational support beams to vertical posts and horizontal joists. While lumber names like “2×8” or “4×6” might seem straightforward, grasping their actual measurements and best uses is vital for making superior building choices and ensuring your project complies with all safety standards and local building codes.

This comprehensive guide will demystify the common lumber sizes used in deck construction. We will explore five primary types of structural lumber, detail their real dimensions after processing, and illustrate how they work together to form a robust framework. Furthermore, we’ll delve into why lumber measurements differ from their nominal names and provide practical advice on how to select the right size for each specific part of your deck, helping you build a beautiful and secure outdoor living space that stands the test of time.

The Essentials of Lumber Sizing: Understanding Nominal vs. Actual Dimensions

What are Nominal Lumber Sizes?

The names given to pieces of lumber often do not reflect their true, finished dimensions. The size we commonly refer to, such as a “2×8” or “4×6” board, is known as the nominal size. This term represents the rough, initial dimensions of the wood immediately after it’s cut from a log at the lumber mill. These traditional names have been used for decades and serve as a standard way to identify and order lumber. However, it’s critical to remember that the wood you purchase and build with will be smaller once it has undergone the complete manufacturing process.

The Critical Difference Between Nominal and Actual Sizes

The discrepancy between nominal and actual lumber sizes is a fundamental concept in construction. This difference arises from the various stages lumber goes through after the initial rough cut. These processes — primarily drying and planing — reduce the wood’s dimensions to achieve stability, uniformity, and a smooth finish. Knowing the actual measurements is indispensable for accurate design, precise cutting, and ensuring that all structural components fit together correctly and meet engineering specifications. Let’s look at concrete examples frequently encountered in deck building:

- A “2×8” board (nominal) actually measures approximately 1.5 inches in thickness by 7.5 inches in width.

- A “4×8” beam (nominal) comes out as roughly 3.5 inches in thickness by 7.5 inches in height.

- A “2×6” piece (nominal) ends up as about 1.5 inches in thickness by 5.5 inches in width.

- A “4×6” post (nominal) measures approximately 3.5 inches in thickness by 5.5 inches in width.

- A “4×4” post (nominal) becomes roughly 3.5 inches by 3.5 inches, forming a square.

While these are the standard actual dimensions, slight variations can occur between different lumber mills due to their unique processing methods. For instance, the actual width of a 2×8 board might range from 7.25 to 7.75 inches from one supplier to another. Always verify the actual dimensions of the lumber you plan to use, especially for critical structural components, to prevent costly errors during construction.

Why Do These Discrepancies Exist? The Lumber Manufacturing Process

The difference in size is not arbitrary; it’s a direct outcome of the sophisticated lumber manufacturing process, which aims to produce high-quality, standardized building materials. Here’s a step-by-step explanation of how lumber sizes change from rough cut to finished product:

- Initial Sawing: Lumber mills begin by cutting logs into rough timber pieces that correspond to the nominal dimensions (e.g., 2×8 inches). These initial cuts are slightly oversized to account for subsequent material removal.

- Drying (Seasoning): The wood is then subjected to a drying process, often in large kilns, to significantly reduce its moisture content. Drying is essential to prevent warping, shrinking, and cracking after installation, and to enhance the wood’s stability and strength. As wood loses moisture, it naturally shrinks, leading to a reduction in its overall dimensions.

- Planing (Surfacing): After drying, the rough-sawn lumber is run through a planer machine. This process, known as surfacing or S4S (surfaced four sides), smooths all four faces of the wood, making it uniform in thickness and width, easier to handle, and safer to work with. Each pass through the planer removes a small amount of material, further reducing the dimensions to their final actual size.

- Pressure-Treatment (for Outdoor Use): For lumber intended for exterior applications like decks, it undergoes pressure treatment. This process forces chemical preservatives deep into the wood fibers, providing crucial protection against rot, decay, and insect infestation. While it doesn’t significantly change the dimensions, it’s a vital step for the longevity of deck lumber.

- Grading and Bundling: Finally, the finished lumber is inspected, graded based on quality and structural characteristics, and then bundled for shipment to suppliers. The end result is a finished board or beam that is consistent, smooth, and ready for construction, albeit smaller than its nominal designation.

Understanding this intricate process clarifies why nominal sizes are merely a reference, while actual sizes are the precise measurements you’ll work with on your building site, directly impacting the fit, strength, and compliance of your deck.

The 5 Most Commonly Used Lumber Sizes in Deck Construction

1. 2×8 Lumber: The Essential Backbone of Deck Framing

The 2×8 board stands as a fundamental and indispensable component in almost any deck building project. Despite its nominal name suggesting a 2-inch by 8-inch cross-section, its finished dimensions are slightly smaller, a critical factor that influences its application and load-bearing capabilities. This lumber size is commonly used to form the primary structural framework that directly supports the deck surface.

Dimensions: Milled to Approximately 1.5 Inches by 7.5 Inches

After being processed through the mill—including drying and planing—a nominal 2×8 board will typically measure an actual 1.5 inches in thickness and 7.5 inches in width. As previously noted, minor variations in width (e.g., between 7.25 and 7.75 inches) might occur depending on the specific manufacturer’s standards. These precise dimensions are crucial when calculating span distances, selecting appropriate joist hangers, and ensuring proper connections for ledger boards.

Typical Uses: Deck Joists, Rim Joists, and Ledger Boards

2×8 lumber primarily serves as a main structural element in deck framing. You’ll find these boards extensively used as:

- Deck Joists: These are the horizontal members that run perpendicular to the beams and posts, forming the grid upon which the deck boards are fastened. They are crucial for distributing the weight from the deck surface (including live loads like people and furniture) down to the support beams and ultimately to the posts.

- Rim Joists: These boards cap the ends of the joists, forming the outer perimeter of the deck frame. They help to square and unify the entire structure, provide a nailing surface for skirting or fascia, and offer additional rigidity to the deck’s edges.

- Ledger Boards: When a deck is attached to an existing building, a ledger board (often a 2×8 or 2×10) is securely bolted to the house’s band joist. This forms one side of the deck frame, firmly anchoring the deck to the building and transferring loads to the house’s foundation.

Code Compliance Considerations for Spanning Distances and Spacing

The structural integrity and safety of your deck depend heavily on the correct placement and spacing of 2×8 joists. Building codes dictate specific limitations on the span (the maximum unsupported distance a joist can cover) for a given lumber size, species, and grade. Exceeding these limits can lead to excessive deflection, making the deck feel bouncy, unstable, and potentially unsafe. Typical joist spacing for 2x8s in decks is 16 inches on center, but this can vary based on the type of deck board material (e.g., composite decking often requires 12-inch spacing to prevent sagging) and local code requirements. Always consult your local building department’s span tables and obtain necessary permits to ensure your deck meets all structural requirements and safety guidelines. Proper beam support at set points is also essential for safe 2×8 joist spans.

2. 4×8 Lumber: Essential for Robust Beam Support

Building a strong and enduring deck requires careful selection of primary support beams. The 4×8 lumber perfectly fills this role, offering enhanced strength and key benefits for the deck’s structural integrity, especially where substantial load-bearing is required.

Dimensions: Milled to 3.5 Inches by 7.5 Inches

Like other lumber types, a nominal 4×8 board starts larger at the mill as a true 4-inch by 8-inch piece. However, after the essential processes of drying and planing, its final actual measurements become approximately 3.5 inches in thickness and 7.5 inches in height (or width, depending on how it’s oriented in the structure). These substantial dimensions contribute directly to its increased load-bearing capacity and resistance to bending. These boards are also typically pressure-treated to ensure maximum durability and resistance to outdoor elements, making them ideal for long-term structural use in decks.

Primary Use: Beams for Added Structural Support

The main purpose of 4×8 lumber in deck construction is to serve as robust support beams, also often referred to as girders. These thick, strong boards are strategically positioned underneath the joists to effectively transfer the entire deck’s weight, along with any live loads (such as people, furniture, and snow), down to the support posts. By providing a solid and unyielding foundation, 4×8 beams play a critical role in distributing the load efficiently throughout the structure, preventing sag, bounce, and ensuring the overall stability and safety of the deck. For even greater load capacity or longer spans, multiple 4x8s can be fastened together to form double or triple beams.

Ideal for Low Decks Where Space Is Limited

One of the distinct advantages of utilizing 4×8 beams is their relatively compact profile, which makes them exceptionally well-suited for applications where vertical space is a constraint, particularly in low-profile deck designs. When designing a deck with a minimal step-down from an existing door or building a ground-level deck, every inch of height clearance is valuable. A 4×8 beam, with its 7.5-inch actual height, can be integrated more efficiently into a low deck design compared to taller options like 2×10 or 2×12 beams, which might necessitate more extensive excavation or result in an undesirably high deck. For example, if you have at least 16 inches of available space from the ground to the bottom of your deck boards, you can comfortably place a 4×8 beam and then add a 2×8 joist on top, creating a stable and code-compliant support system without wasting precious vertical space.

3. 2×6 Lumber: Versatile for Blocking, Bridging, and Secondary Supports

While 2×6 lumber may not typically be the primary load-bearing beam or joist in most standard deck constructions, it plays a specific yet critical role in enhancing the stability, rigidity, and overall structural integrity of the deck frame. Its more compact dimensions make it an ideal choice for specific reinforcement and support applications that complement larger structural members.

Dimensions: Approximately 1.5 Inches by 5.5 Inches

After undergoing the standard milling, drying, and planing processes, a nominal 2×6 board will reliably measure an actual 1.5 inches in thickness and 5.5 inches in width. This more slender profile, when compared to larger joists like a 2×8, is precisely what makes it perfectly suited for its specialized functions within the deck framework, particularly when it needs to fit snugly between larger components without adding excessive bulk or interfering with other elements.

Common Uses: Blocking and Bridging Between Joists

The primary and most essential application of 2×6 lumber in deck building is for blocking (also frequently referred to as “pressure blocking” or “solid blocking”) and bridging. These vital elements are installed perpendicular to the joists at specific intervals along their span, usually at mid-span or over supporting beams. Their main purposes are multifaceted and crucial for a long-lasting deck:

- Adding Stability to the Frame: Blocking effectively prevents individual joists from twisting, bowing, or warping over time. This helps to maintain a consistently level and flat deck surface, reducing unsightly undulations.

- Enhancing Rigidity: By tying all the joists together into a unified system, blocking distributes loads more evenly across the entire frame. This significantly reduces the sensation of bounce or vibration when walking on the deck, making it feel much more solid and robust.

- Supporting the Overall Deck Design: In some instances, blocking can provide crucial additional nailing surfaces for fastening deck boards, especially where deck board seams need support or for intricate perimeter detailing.

- Load Transfer: Blocking can also help transfer concentrated loads from one part of the deck to adjacent joists, further improving the structural performance.

Bridging, which can be either solid blocking or diagonal cross-bracing, serves a similar purpose in stiffening the overall floor system and improving lateral stability.

Advantages of Using 2×6 for Blocking to Prevent Issues with Deck Boards

Choosing 2×6 lumber for blocking instead of using larger 2×8 pieces that would need to be cut down offers several clear and practical benefits during the construction phase:

- Optimal Height and Clearance: A 2×6 block (with an actual height of 5.5 inches) sits conveniently lower than the top edge of a 2×8 joist (which has an actual height of 7.5 inches) by two inches. This creates a vital clear space beneath the planned level of the deck boards. This clearance is crucial as it prevents the blocking from interfering with deck board fasteners or from creating an uneven pressure point that could “telegraph” the presence of the blocking through the finished deck board surface over time.

- Simplified and Faster Installation: Since 2x6s are inherently shorter than typical joist heights, they do not need to be meticulously cut to the exact height of the joist. This significantly speeds up the installation process and reduces the need for frequent, precise cuts for every single blocking piece, saving time and labor costs.

- Improved Deck Board Laying: The lower profile of 2×6 blocking ensures that deck boards can be laid flat and installed easily without encountering obstructions. This efficiency helps construction workers maintain consistent progress and greatly reduces potential problems or unsightly bumps that could arise when laying the top deck boards.

- Secondary Uses: Beyond blocking, 2x6s can also be utilized for lighter-duty stair stringers, or as support for non-structural infill within railing systems, offering a lightweight yet sufficiently sturdy option for these applications.

4. 4×6 Lumber: A Solid Choice for Posts, Beams, and Taller Structures

When deck building demands superior strength, enhanced stability, and robust resistance to deflection, 4×6 lumber emerges as an exceptionally reliable and often preferred option for crucial vertical and horizontal support elements. It effectively balances significant structural integrity with a manageable size, making it highly versatile for a variety of demanding applications in deck construction.

Dimensions: Roughly 3.5 Inches by 5.5 Inches

Adhering to industry standard milling processes, a nominal 4×6 piece of lumber will consistently achieve actual dimensions of approximately 3.5 inches in thickness by 5.5 inches in width (or height, depending on its orientation within the structure). These substantial dimensions provide a significantly larger cross-sectional area compared to a 4×4, directly translating into enhanced load-bearing capacity and increased resistance to bending or twisting under the various stresses a deck experiences. Like other high-performance deck lumber, 4x6s are typically pressure-treated to ensure longevity and superior protection against environmental decay, rot, and insect damage.

Common Applications: Robust Support Posts, Heavier Beams, and Vertical Elements

4×6 lumber offers considerable versatility and superior strength, making it suitable for several key roles in deck building:

- Primary Support Posts: It excels as robust support posts, particularly for decks that are elevated, designed to carry heavier loads (such as hot tubs or large gatherings), or require greater resistance to lateral forces like wind and seismic activity. Its larger face provides more ample surface area for secure connections to beams and footings.

- Strong Intermediate Beams: Beyond its use as posts, 4x6s can function as sturdy intermediate beams or girders, especially when combined in multiple plies (e.g., two or three 4x6s bolted together) to create even greater span capabilities and load-bearing capacity for larger or more complex deck designs.

- Vertical Supports for Skirting: While 4x4s can be used for light-duty skirting framing, 4x6s offer a more substantial and stable framework for attaching decorative or protective deck skirting, providing a more robust base.

- Structural Rail Posts: For deck railings that require exceptional sturdiness and resistance to movement (especially at corners or stair transitions), 4×6 posts provide excellent anchoring points and significantly contribute to the structural integrity and safety of the entire railing system.

- Joining Different Deck Sections: In multi-level or complex deck designs, 4x6s can serve as strong connecting elements between different deck sections, ensuring cohesive and stable construction across varying elevations.

- Supporting on Top of Walls: When building a deck on top of a retaining wall or an existing foundation, 4x6s can be used as a sill plate or additional support to distribute loads evenly and provide a solid attachment point for the rest of the deck frame.

Comparison with 4×4: Superior Strength and Reduced Cracking

When selecting lumber for structural roles in deck construction, the 4×6 lumber presents several compelling advantages over the smaller 4×4, making it a safer and more durable choice for most primary applications:

- Significantly Greater Structural Strength: With a larger cross-sectional area (3.5″ x 5.5″ vs. 3.5″ x 3.5″), a 4×6 can handle considerably more compressive and bending load and resist forces far better than a 4×4. This makes it inherently more suitable for primary support posts on elevated or larger decks.

- Enhanced Stability and Rigidity: The wider face (5.5 inches compared to 3.5 inches) of a 4×6 provides superior lateral stability, substantially reducing the likelihood of the post twisting, racking, or experiencing excessive sway, particularly when subjected to wind or other lateral forces.

- Less Prone to Splitting and Cracking (Checking): While all lumber can experience checking (cracks that develop along the grain as wood dries), the larger dimensions of a 4×6 tend to distribute internal drying stresses more effectively. This often results in fewer, shallower, and less structurally compromising checks compared to 4x4s, which are notoriously prone to developing significant and deep splits, especially in outdoor, exposed conditions. This resilience contributes significantly to both the longevity and the long-term aesthetic appeal of the deck.

- Better for Secure Connections: The larger surface area of a 4×6 provides more ample space for creating secure and robust connections using bolts, lag screws, or specialized structural hardware, further enhancing the overall structural integrity and safety of the deck.

For any significant load-bearing application in modern, code-compliant deck building, a 4×6 is almost always a superior, safer, and more durable choice over a 4×4.

5. 4×4 Lumber: Lightweight Support for Non-Primary Structures

While 4×4 lumber has been a common sight in older deck designs or for very small, non-elevated structures, its role in modern, code-compliant deck construction is more specific and limited. It offers lightweight support and is best suited for less demanding parts of the structure where significant load-bearing capacity is not the primary requirement or for decorative purposes.

Dimensions: Approximately 3.5 Inches Square

After undergoing the standard milling process, a nominal 4×4 piece of lumber will measure an actual 3.5 inches by 3.5 inches, forming a perfect square cross-section. This uniform square design makes it easily identifiable and useful for certain light-duty building needs. However, its relatively smaller mass and cross-sectional area compared to 4x6s or larger beams significantly limit its structural applications, especially for elevated decks that must meet stringent building codes.

Common Uses: Light-Duty Posts, Skirting Support, and Spacing

4×4 lumber can be effectively used in several situations where its strength limitations are thoroughly understood and appropriately accounted for:

- Supporting Deck Skirting: It is frequently used to frame the decorative skirting around the perimeter of a deck, providing a non-structural framework for attaching lattice, vertical boards, or other enclosure materials. In this role, the 4x4s are not bearing the primary structural load of the deck itself.

- Adding Spacing or Blocking Where Needed: Due to its consistent square profile, 4x4s can be precisely cut and used as spacers or blocks within the frame where specific dimensions are required for non-load-bearing infill or to create attachment points.

- Serving as Light Vertical Supports for Very Low Decks: For extremely low-level decks (e.g., just a few inches off the ground) or small, non-elevated landings, 4x4s might occasionally serve as very short support posts. However, rigorous adherence to local building codes regarding permissible heights and loads is absolutely critical.

- Filling Gaps or Creating Transitions: In certain complex or multi-level deck designs, 4x4s can be utilized as non-structural infill or transition pieces between different deck sections or varying elevations, provided they are not carrying significant loads.

- Helping with Smaller Ancillary Building Tasks: For garden beds adjacent to the deck, small decorative fences attached to the deck, or other minor ancillary structures, 4x4s often offer a convenient and cost-effective option where heavy structural demands are absent.

Limitations Compared to 4×6 and Situations Where It’s Best Suited

Understanding when to appropriately use 4x4s versus more robust lumber sizes is paramount for safe, durable, and code-compliant construction. Its limitations are quite significant for primary deck structures:

- Significantly Less Structural Strength than 4×6: A 4×4 has a considerably smaller cross-sectional area than a 4×6, meaning it can withstand far less compressive force, bending stress, and lateral load. This makes it generally unsuitable for primary support posts on elevated decks or for carrying heavy, concentrated loads.

- Higher Propensity for Cracking and Checking: Due to its relatively uniform thickness and position within the log, 4×4 lumber is notoriously prone to developing deep checks and splits as it dries and is exposed to the elements. These cracks can severely compromise its structural integrity over time and diminish its aesthetic appeal.

- Best for Light-Duty, Non-Load-Bearing Tasks: 4x4s are most appropriate for applications where they are not solely responsible for supporting significant weight or resisting strong lateral forces. They are ideal for secondary, non-critical, or decorative supports.

- Limited for Primary Deck Posts: Many modern building codes and best practices strongly discourage or even prohibit the use of 4x4s as primary support posts for elevated decks due to their inherent structural weakness and tendency to check severely. If permitted, their maximum height and span capabilities are extremely limited and must be strictly adhered to.

- Suits Basic Framing Needs for Non-Critical Areas: If you are constructing a very simple, low-to-the-ground platform that is not intended for heavy use, or for non-critical elements like handrail infill, 4x4s can suffice. However, for the main structural elements of any deck that will see regular use and support substantial loads, a 4×6 or larger post is almost always recommended for superior safety, stability, and longevity.

Lumber Types and Grades: Ensuring Quality and Performance

Understanding Lumber Grades

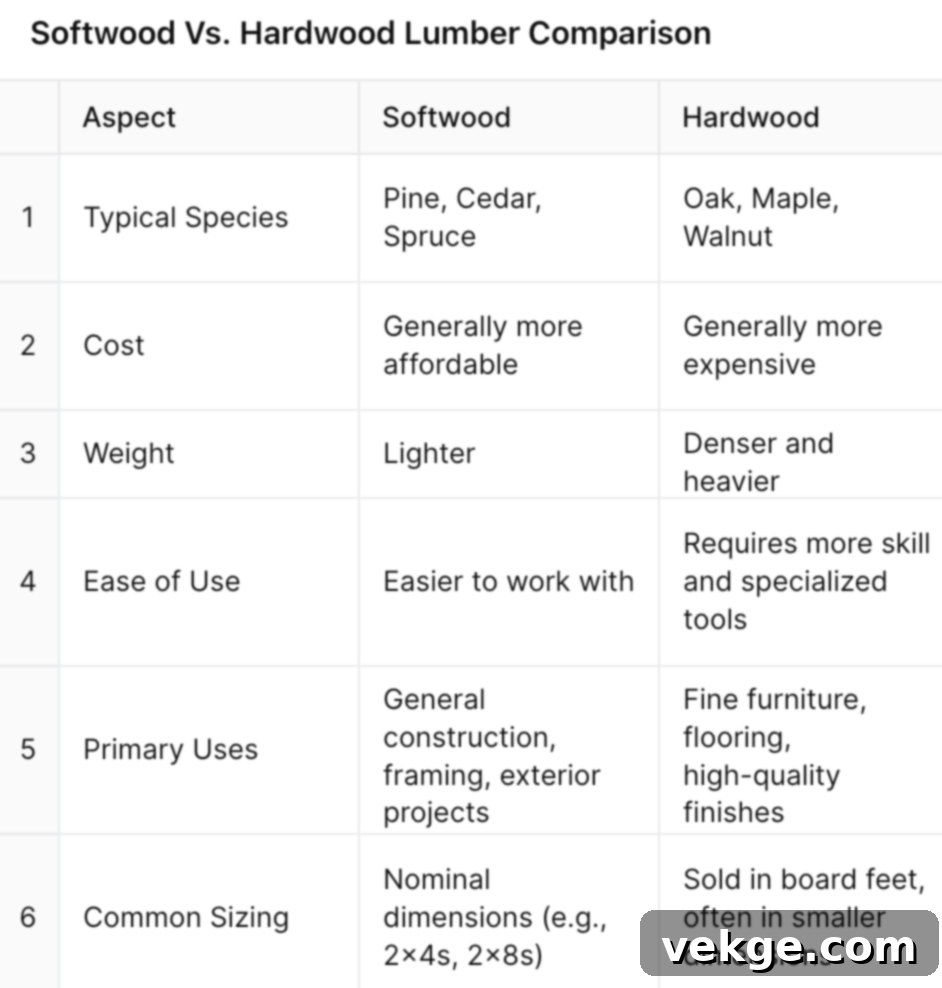

Lumber grades represent a standardized classification system used to evaluate the quality of wood based on various critical factors, including its inherent strength, overall appearance, and the presence and severity of natural defects. This grading system is indispensable for both builders and consumers, as it facilitates the selection of the most appropriate wood for specific applications, thereby ensuring both structural integrity and desired aesthetic appeal. Different categories of lumber, notably softwood and hardwood, are graded using slightly varying criteria due to their distinct primary uses and performance expectations.

Softwood Lumber Grading: Softwoods, encompassing species like pine, spruce, and fir, are predominantly utilized in construction due to their favorable strength-to-weight ratio, abundance, and ease of workability. Consequently, softwood lumber is primarily graded based on its structural soundness and its suitability for load-bearing applications. The grading process meticulously accounts for defects that could potentially compromise the wood’s ability to safely carry weight or resist various structural forces.

Hardwood Lumber Grading: Hardwoods, including species such as oak, maple, and cherry, are highly valued for their superior aesthetic qualities, exceptional durability, and suitability for applications like fine furniture, high-quality flooring, and intricate decorative elements. Therefore, hardwood lumber grading places a significantly greater emphasis on appearance, specifically focusing on the amount of clear (defect-free) wood available for precise cutting and achieving a premium finish.

Common Softwood Grades for Deck Construction: No. 1 vs. No. 2 Common

For deck building, which primarily relies on softwood lumber, two common grades are frequently encountered and widely available: No. 1 Common and No. 2 Common. A thorough understanding of their distinctions is paramount for making informed material selections for the various components of a safe and durable deck.

No. 1 Common Grade Lumber

This grade signifies a higher quality of structural lumber, characterized by a reduced number and smaller size of knots, minimal wane (missing wood or bark on the edge of the board), and fewer other imperfections. Lumber graded as No. 1 Common offers superior structural integrity, enhanced strength, and a more uniform, aesthetically pleasing appearance. It is typically characterized by having sound, tight knots that are generally small and infrequent, making it an excellent choice for applications where both robust strength and a clean, consistent look are paramount. For critical deck construction components, No. 1 Common is often specified for:

- Primary Load-Bearing Applications: Such as main support beams, girders, and joists, where the wood must reliably withstand significant weight, compressive forces, and bending stress over long periods.

- Exposed Structural Elements: Where long-term durability, minimal maintenance, and a visually consistent appearance are crucial for the deck’s longevity and aesthetic appeal, such as visible joists or stringers.

- Longer Spans: Its superior strength properties often allow for greater span distances between supports, which can potentially reduce the overall number of posts or beams required, simplifying the foundation.

No. 2 Common Grade Lumber

This grade of lumber includes a greater number of visible knots, and these knots may be larger or more numerous, along with other minor imperfections, compared to No. 1 Common. While still structurally sound for many applications, these more pronounced defects can subtly impact its overall structural strength to a degree, and its appearance is notably less refined. No. 2 Common is generally a more economical option and is often utilized in situations where:

- Non-Load-Bearing or Secondary Applications: For elements like blocking between joists, the framing for deck skirting, or other areas where the wood is not performing critical primary structural support functions.

- Hidden or Less Visible Areas: Where the aesthetic appearance of the wood is not the primary concern, such as components located on the underside of a deck that will be concealed, or interior framing members.

- Shorter Spans or Reduced Loads: When used for joists or beams, No. 2 Common might necessitate shorter span distances or be suitable for lighter-duty decks, always in strict compliance with local building codes and engineering specifications.

- Deck Boards (with careful selection): For deck boards, No. 2 Common can be used, but careful selection to avoid large, loose knots or significant defects on the walking surface is advisable for both safety and appearance.

Impact of Defects on Lumber Selection

Defects inherent in natural wood, such as knots, splits, checks (cracks along the grain due to drying), wane (missing wood or bark on the edge), various forms of warp (including bow, cup, and twist), and insect damage, can significantly affect both the structural strength and the aesthetic appearance of lumber. Knots, for instance, are natural imperfections where branches once grew; while small, tight, and sound knots may have minimal impact on strength, large, loose, or unsound knots can substantially reduce a board’s load-carrying capacity. Splits and checks, particularly deep ones that penetrate far into the cross-section, can compromise the wood’s structural integrity by reducing its effective load-bearing area.

Experienced builders meticulously choose lumber grades based on the project’s precise structural requirements and desired aesthetic outcomes. For instance, the main support beams, girders, and joists of a deck, which are absolutely critical for safety and the deck’s long-term performance, would necessitate No. 1 Common or even “Select Structural” grade lumber (which is an even higher, premium grade) to ensure maximum strength, reliability, and minimal deflection. Conversely, for a less critical structural component, such as the framing for deck skirting or internal blocking, No. 2 Common grade lumber could safely and economically be utilized.

For deck boards, railing components, or other exposed wood where a smooth, attractive finish without visible flaws is desired, higher grades with fewer imperfections are often selected to achieve a premium look. Choosing the right grade not only directly impacts the safety, stability, and durability of the deck but also its final visual appeal and the overall longevity of your significant investment. Always prioritize structural integrity over cost savings in load-bearing applications.

The Importance of Pressure-Treated Lumber for Decks

Given that decks are exterior structures constantly exposed to harsh weather conditions, moisture, and potential pest infestations, it is absolutely essential to use pressure-treated lumber for all structural components that are in contact with the ground or directly exposed to the elements. Pressure treatment is a specialized industrial process that involves infusing wood with powerful chemical preservatives under high pressure. This process deeply penetrates the wood fibers, providing crucial, long-term protection against common outdoor threats such as rot, fungal decay, and destructive insect infestations (like termites) that would rapidly degrade untreated wood.

There are different levels of pressure treatment, categorized by the retention of preservatives in the wood, making them suitable for various exposure conditions:

- Above Ground (UC3B): This treatment level is suitable for components that are fully exposed to weather but are not in direct contact with the ground and are designed to easily shed water, such as deck joists and railings that are elevated.

- Ground Contact (UC4A): This higher treatment level is specifically required for lumber that is in direct contact with the soil, fresh water, or for components that are critically important and difficult to replace (such as deck posts embedded in concrete or directly buried in the ground). Most deck structural lumber, especially posts and beams, typically falls into this category for enhanced safety and longevity.

- Severe Exposure / Saltwater Splash (UC4B, UC4C): Even higher levels exist for extreme conditions, though less common for typical residential decks.

Always ensure that the lumber you select for your deck is appropriate for its intended exposure conditions and is clearly labeled with the correct treatment level and preservative type. This crucial step guarantees that your deck remains structurally sound, safe, and resistant to environmental degradation for many years to come, maximizing your investment and peace of mind.

Summing Up: Building a Durable and Compliant Deck

Constructing a safe, stable, and durable deck is a meticulous process that fundamentally hinges on a thorough understanding of lumber sizes, their precise actual dimensions, and their appropriate applications within the structure. Every single piece of wood, from the hardworking 2×8 joists that form the essential surface support to the robust 4×6 support posts securely anchored to the ground, contributes uniquely and critically to the overall structural integrity of your outdoor living space. The knowledge of the often-significant difference between nominal and actual lumber sizes is not merely an academic detail; it is a fundamental requirement for accurate design, precise construction, and ensuring your deck meets all local building codes, engineering specifications, and stringent safety standards.

By carefully discerning which specific lumber size and grade best suit particular structural needs—be it for critical load-bearing support, for enhancing frame rigidity through strategic blocking, or for crafting the perfect finishing touches—builders can construct decks that are not only aesthetically pleasing but also exceptionally long-lasting, resilient, and secure. Always remember that a deck represents a significant structural addition to your home, and its safety, functionality, and longevity are directly dependent on the quality of materials used and the precision of its construction. Therefore, it is always advisable to thoroughly consult local building codes, diligently obtain all necessary permits, and proactively seek expert advice from experienced builders, structural engineers, or reputable lumber suppliers when in doubt. Investing your time and effort in proper planning, informed material selection, and meticulous execution will undoubtedly pay significant dividends in the form of a beautiful, safe, and enduring outdoor living space for you and your family to enjoy for many years to come.

Frequently Asked Questions About Deck Lumber Sizes

What are Common Rough Cut Lumber Sizes?

Common rough cut lumber sizes typically correspond to their nominal dimensions before any planing or extensive processing. These can include 1×6, 2×4, 2×6, 2×8, 2×10, 2×12, 4×4, 4×6, and 4×8 inches, among others. These figures represent the approximate dimensions of the wood as it is initially sawn directly from the log, prior to any drying, surfacing, or pressure-treating processes that ultimately reduce its size to the actual dimensions found in finished, ready-to-use lumber.

Is it Cheaper to Buy Rough Cut Lumber?

Generally, yes, rough-cut lumber is often cheaper per board foot compared to finished (surfaced on all four sides) lumber. This cost difference arises because rough-cut lumber has not undergone the additional labor-intensive and equipment-costly processes of extensive drying, planing, and sometimes precise grading that finished lumber requires. Rough-cut lumber is a particularly cost-effective option for DIY and rustic projects where precise, smooth dimensions aren’t critically necessary, or for applications where its natural, uneven texture is specifically desired. However, it’s important to note that if a smooth, finished look is eventually required, the builder will need to perform additional work (e.g., planing it smooth themselves), which can offset some of the initial material cost savings.

How Do I Calculate How Much Lumber I Need for My Deck?

Calculating your deck’s lumber needs involves several systematic steps: First, create a detailed sketch or blueprint of your deck design, including all dimensions. Next, determine the number and precise lengths of all joists, beams, and posts based on your deck’s overall size and, crucially, local building code span tables. Remember to also account for rim joists, ledger boards (if attached to a house), blocking between joists, and the specific decking boards for the surface. It is always a wise practice to add an extra 10-15% to your total material estimates for unforeseen cuts, waste, and potential errors during construction. Many reputable online deck calculators and design software can also significantly assist in accurately estimating material quantities once you input your specific design parameters.

What is the Best Type of Wood for Decking Boards?

For decking boards (the surface layer you walk on), there are several excellent and popular choices, each with unique characteristics. These include pressure-treated pine, naturally rot-resistant cedar, redwood, and various high-performance composite or PVC decking materials. Pressure-treated pine is a highly economical and durable option, especially when properly installed and maintained. Cedar and redwood offer superior natural resistance to rot and insects, along with attractive aesthetics, but typically require more frequent maintenance (like sealing) to preserve their appearance. Composite and PVC decking materials are renowned for being exceptionally low-maintenance, highly durable, and resistant to rot, insects, fading, and splintering, though they generally represent a higher upfront investment compared to traditional wood options.

Why Do My Deck Boards Need Specific Spacing?

Deck boards require specific, uniform spacing between them for several critical reasons essential to the deck’s longevity, safety, and performance. Firstly, adequate spacing allows for proper water drainage, preventing puddles from forming on the deck surface, which could lead to accelerated rot, mildew growth, and staining. Secondly, it ensures sufficient ventilation beneath the deck boards, which helps to keep the wood dry and reduces the risk of moisture-related issues. Most importantly, this spacing accommodates the natural expansion and contraction of wood or composite materials due to fluctuating temperature and humidity levels. Without proper gaps, deck boards can buckle, warp, or crack as they expand, potentially damaging the deck structure, creating unsightly unevenness, or even posing tripping hazards. The recommended gap typically ranges from 1/8 to 1/4 inch, depending on the material type, local climate, and specific manufacturer guidelines.