Stokbord®: The Sustainable Recycled Plastic Sheet Revolutionizing Modern Building Materials

For generations, traditional building materials such as timber and plywood have been the undisputed champions in construction, agriculture, and various industrial applications. While these materials have served us well, the modern world demands more. With ever-evolving industry standards, environmental concerns, and a need for greater efficiency, there’s a growing demand for sustainable, versatile, cost-effective, and user-friendly alternatives. This is precisely where Stokbord® steps in, offering an innovative solution that outperforms conventional options on multiple fronts.

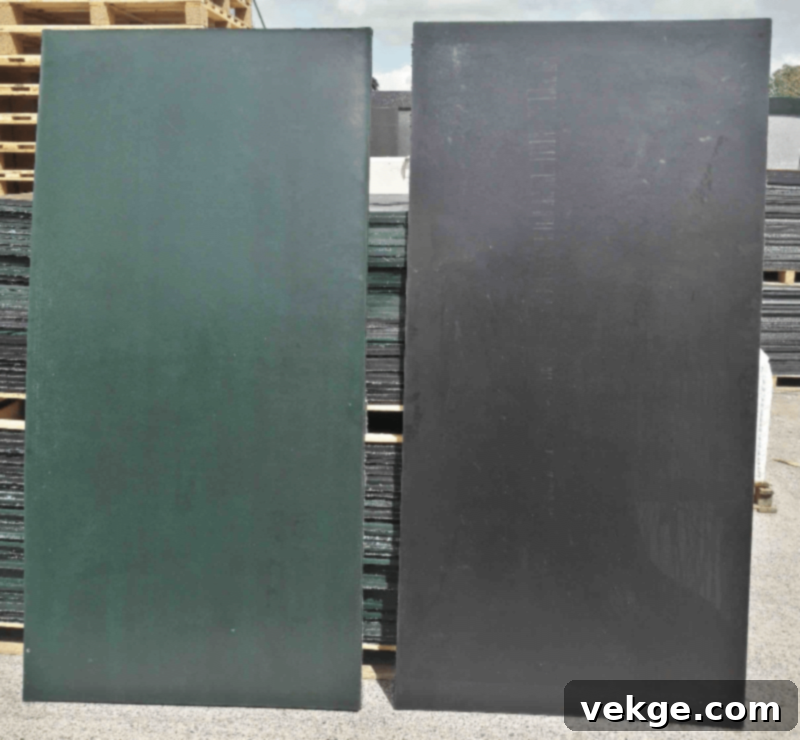

Stokbord®, widely known as stockboard recycled plastic, is a revolutionary rigid yet lightweight sheet material. Engineered from 100% recycled polyethylene, it offers a unique combination of properties that surpass the limitations of timber, plywood, and even some steel applications. By giving new life to waste plastic, Stokbord® embodies an eco-friendly approach to construction and design. But what exactly makes these general-purpose boards so special, and where are stockboard sheets typically used? From robust construction projects and durable agricultural fencing to hygienic poultry housing and resilient industrial applications, Stokbord® provides unparalleled performance and adaptability.

Unmatched Versatility for Diverse Applications

The inherent versatility of Stokbord® is arguably one of its most compelling advantages, making it suitable for an extensive array of projects. Beyond simply purchasing stockboard recycled plastic in standard full sheets or convenient cut-to-size boards, the material’s adaptability extends to bespoke fabricated sheets tailored for highly specific applications. Stokbord® sheets can be easily manipulated through various fabrication methods, including precise routing, clean cutting, and intricate shaping. This ease of customization ensures that Stokbord® can be perfectly adapted to virtually any design requirement, providing a seamless fit and finish for every project, big or small.

Standard Stokbord® sheets are typically available in a practical size of 2440mm x 1220mm, with common thicknesses ranging from 6mm, 9mm, and 12mm. However, the scope for customization is vast. Depending on your supplier and their minimum order quantities, Stokbord® can be custom-produced in a broad spectrum of thicknesses, from a slender 2mm up to a robust 25mm. Furthermore, sheet sizes can be precisely tailored to maximum dimensions of 3660mm in length and 1525mm in width, offering incredible flexibility for large-scale or unique architectural designs.

In the construction sector, Stokbord® finds extensive use as durable wall cladding, resilient soffits, robust partitions, and hard-wearing flooring. Its exceptional resistance to moisture, chemicals, and impact makes it a superior choice for environments where exposure to dampness or harsh conditions is a concern. This leads us seamlessly to its outstanding performance in agriculture, an industry where its unique properties truly shine.

Within agricultural settings, Stokbord® excels in a myriad of projects. Its impressive resistance to high-pressure washing, heavy impact, and aggressive cleaning chemicals makes it ideal for livestock housing and feeding areas. Crucially, Stokbord® is non-toxic, ensuring absolute safety for animals. This makes it the preferred material for stable partitions, durable pig pens, hygienic chicken coops, and various animal enclosures. Farmers can have complete peace of mind knowing that curious animals, prone to gnawing, will not ingest harmful toxins or compromise the structural integrity of their enclosures. Its smooth, non-porous surface also deters bacterial growth, contributing to a healthier environment for livestock.

Unrivaled Durability and Longevity

One of the most significant advantages of stockboard plastic sheets over traditional timber is their inherent durability. Unlike wood, which is susceptible to warping, cracking, rotting, and insect infestations over time, Stokbord® sheets are dimensionally stable. They boast exceptional resistance to moisture absorption, ensuring they retain their shape and structural integrity even in damp or wet conditions. This makes them perfectly suited for outdoor applications and areas prone to high humidity.

Furthermore, Stokbord® demonstrates impressive impact resistance, capable of withstanding significant forces without denting or shattering, a critical feature for high-traffic areas or environments where accidental impacts are common. They also offer a commendable weight-bearing capacity, making them a robust and reliable choice for certain load-bearing applications where structural stability is paramount.

Beyond physical resilience, Stokbord® is engineered to be highly UV-resistant. This vital property means that the material retains its structural integrity and aesthetic appeal even when exposed to prolonged and harsh sunlight. This resistance prevents fading, degradation, and embrittlement, ensuring a long-lasting visual and functional performance in outdoor environments. For applications requiring extra surface protection, Stokbord® sheets featuring embossed surface patterns on both sides provide enhanced scratch resistance. This makes them an excellent choice for demanding uses such as durable van flooring, where everyday wear and tear is a constant concern.

These collective hard-wearing properties of Stokbord® sheets directly translate into a significantly longer lifespan for your projects. This extended durability dramatically reduces the need for frequent maintenance, costly repairs, and premature replacement that are often associated with less resilient materials. Opting for Stokbord® means investing in a solution that offers superior longevity and reliability, saving both time and money in the long run.

A Pillar of Sustainability in Modern Construction

As the adage goes, modern problems require modern solutions. In an era where sustainability is not just a buzzword but a critical imperative for all industries, Stokbord® offers a readily accessible and impactful part of the solution. The environmental benefits of choosing Stokbord® are substantial and far-reaching.

It is widely acknowledged that extensive timber harvesting contributes significantly to deforestation, leading to devastating effects on biodiversity, climate regulation, and ecological balance. Similarly, the production of plywood often involves the use of harsh, potentially harmful chemicals as bonding agents, posing risks to both environmental health and human safety. Stokbord®, however, stands in stark contrast to these practices.

Crafted entirely from 100% recycled polyethylene, Stokbord® represents a non-toxic, safe, and environmentally responsible option. It actively diverts vast quantities of waste plastic – materials that would otherwise languish in landfills for centuries – and transforms them into valuable, high-performance building materials. This not only dramatically reduces our reliance on finite virgin resources but also plays a crucial role in mitigating plastic pollution and fostering a cleaner, healthier planet. Furthermore, the manufacturing process of Stokbord® is designed to be energy-efficient, meticulously minimizing its overall environmental footprint from production to application.

Embracing the Circular Economy: Recyclability

The environmental credentials of Stokbord® extend beyond its origins. Not only is this innovative material manufactured from 100% recycled plastic, but it is also fully recyclable at the absolute end of its incredibly long lifespan. This commitment to a circular approach to material usage is a cornerstone of sustainable industry practices. By ensuring that Stokbord® can be reprocessed and reused, it significantly minimizes waste accumulation and reduces the perpetual demand for new raw resources. This closed-loop system is vital for building a truly sustainable future, where materials are kept in use for as long as possible, minimizing environmental impact at every stage of their lifecycle.

Enhanced Safety Features for Peace of Mind

Stokbord® sheets are generally regarded as exceptionally safe and easy to work with, offering considerable advantages over traditional wood-based products. Unlike timber, which frequently splinters during cutting, handling, or installation, stockboard sheets are inherently splinter-free. This crucial safety feature virtually eliminates the risk of painful injuries, cuts, and accidents for workers, ensuring a smoother, more secure, and hassle-free construction or installation process.

Additionally, working with Stokbord® boards eliminates the health risks associated with wood dust exposure. Fine wood dust particles, especially from certain species, can be irritating to the throat, eyes, and nose. For individuals suffering from allergies or respiratory conditions, prolonged exposure can lead to chronic respiratory illnesses. Stokbord® sheets produce minimal dust when cut or worked on, thereby significantly contributing to a cleaner and safer working environment, protecting the health and well-being of those on site.

It is important to note, however, that Stokbord® typically carries a Class-3 fire rating. This classification indicates a moderate flame spread rate, meaning it will burn slowly when exposed to a flame but is not inherently fire-resistant. While suitable for many general applications, this rating may not meet the stringent fire safety requirements for all domestic or commercial applications, particularly those demanding higher fire resistance.

If fire safety is a paramount factor for your specific project, it is strongly recommended that you consult with a qualified building professional or fire safety expert. They can provide essential guidance on alternative materials, evaluate specific regulations, or explore potential fireproofing solutions that can be effectively combined with Stokbord® recycled plastic to meet local building codes, insurance requirements, and critical safety standards.

Effortless Installation and Workability

In terms of workability and ease of use, Stokbord® sheets are remarkably cooperative. They can be precisely cut with standard woodworking tools, requiring no specialized equipment, which streamlines the fabrication process. Furthermore, compared to many other materials, Stokbord® demands minimal finishing. Its smooth, non-porous surface often requires no painting, sealing, or sanding, directly contributing to quicker project completion times and significantly reduced labor costs. This efficiency translates into tangible savings for any project.

For specific applications, Stokbord® is also weldable, allowing for seamless and strong joints. However, it’s important to note that this process typically requires specialized equipment and a certain level of expertise to achieve optimal results.

While some sources might suggest gluing these boards, it is generally not recommended as a primary fixing method. Over time, adhesive bonds can weaken and fail, potentially compromising the long-term integrity and safety of your project. For robust and reliable connections, Stokbord® sheets are best fixed together using tried-and-tested mechanical methods, such as round-headed screws or, for enhanced stability, a combination of a washer and bolt. These methods ensure a secure and lasting hold, maintaining the structural integrity of your construction.

Long-Term Cost-Effectiveness and Value

When discussing project expenses, Stokbord® consistently offers exceptional long-term value for your investment. While the initial cost per square metre might appear slightly higher than some conventional, cheaper materials like raw timber, it is crucial to consider the comprehensive whole-life cost of the material. This perspective reveals the true economic benefits.

Thanks to its unparalleled durability and resistance to environmental factors, Stokbord® requires remarkably minimal upkeep and maintenance once installed. It doesn’t rot, warp, splinter, or need regular painting or weatherproofing like wood. This drastic reduction in ongoing maintenance, repair, and replacement expenses translates into significant long-term savings. Consequently, Stokbord® emerges as an incredibly intelligent and budget-conscious choice for builders, designers, farmers, and DIY enthusiasts who prioritize both performance and fiscal prudence.

Stokbord®: The Smart Choice for a Sustainable Future

By choosing Stokbord® recycled plastic sheets, you are not merely selecting a high-performance building material that promises years of reliable service; you are actively making a profound and positive impact on the environment. Its journey from waste plastic to a versatile, durable, and safe construction solution embodies the principles of sustainability and innovation.

With all the remarkable benefits and diverse applications detailed above – from its incredible versatility and unmatched durability to its significant contributions to sustainability, recyclability, enhanced safety, and ease of use, coupled with its long-term cost-effectiveness – it is abundantly clear why Stokbord® is rapidly becoming the trusted choice for discerning builders, forward-thinking designers, efficient farmers, and resourceful DIYers. It offers a truly superior, sustainable, and practical alternative to traditional materials like wood, plywood, steel, and beyond, paving the way for a more responsible and resilient future in construction and industry.