DIY Cabinet Doors: A Comprehensive Step-by-Step Guide to Building Your Own

After seven rewarding years dedicated to crafting custom cabinet doors in my bustling workshop, I can confidently share that building your own doors offers unparalleled satisfaction and substantial financial savings. What began as a simple hobby quickly blossomed into a profound passion for creating perfectly fitted, personalized cabinet doors that not only transform the aesthetics of kitchens and storage areas but also significantly enhance their functionality.

Every single project has been a valuable learning experience, deepening my understanding of wood behavior, refining my tool techniques, and reinforcing the critical importance of patience in woodworking. Through countless doors – some achieving immediate success, others serving as crucial learning opportunities – I’ve meticulously developed foolproof methods for consistently achieving professional-quality results. This guide distills years of hands-on experience into clear, actionable steps, empowering you to embark on your own cabinet door-making journey.

Understanding Popular Cabinet Door Styles for DIY Projects

Through years of experimenting with various designs, I’ve discovered that each cabinet door style offers unique aesthetic and structural benefits. Understanding these differences is crucial for choosing the right style for your home and skill level.

Shaker Style: Timeless Elegance for Beginners

The Shaker style has become my go-to recommendation for beginners, thanks to its clean lines and enduring, timeless appeal. Its simple frame-and-panel construction is not only aesthetically pleasing but also an excellent way to learn essential woodworking skills. Shaker doors seamlessly fit into both modern minimalist and traditional rustic kitchen designs, offering incredible versatility. The straightforward design allows you to focus on developing proper joinery and finishing techniques without being overwhelmed by intricate details.

Slab Doors: The Ultimate in Simplicity and Modernity

For those seeking the absolute simplest entry into cabinet door building, slab doors are the answer. These doors are essentially flat panels, often made from a single piece of plywood or MDF, with edge banding applied for a finished look. Their minimalist design makes them perfect for contemporary and modern interiors. They require minimal cuts and joinery, allowing you to focus on precise measurements, smooth edges, and a flawless finish.

Flat Panel Doors: A Step Up from Shaker with More Options

Similar to Shaker, flat panel doors feature a frame (stiles and rails) surrounding a flat center panel. The key difference often lies in the profile of the frame’s inner edge, which can be square, beveled, or slightly coved, offering more design flexibility than the strictly square edges of a Shaker door. This style provides a modern appearance while still being straightforward to construct, making it an excellent choice for DIYers looking to expand their skills slightly beyond basic Shaker.

Step-by-Step Guide to Making Professional-Quality Cabinet Doors

Step 1: Essential Preparation – The Foundation of Success

Before any wood is cut, I always begin with meticulous measurement and detailed planning. This stage is paramount; even a slight error here can ripple through the entire project, leading to ill-fitting or misaligned doors. Each door demands precise dimensions to ensure a perfect fit within its opening and seamless functionality with its hinges. Investing time in careful preparation with the right tools truly makes all the difference in the final quality and greatly reduces the chance of costly mistakes later on. My preparation process is designed to minimize errors and maximize the chances of achieving impeccable results.

Detailed Measuring Steps for Accuracy:

- Measure Cabinet Openings Twice: Always measure the width and height of each cabinet opening at least twice, and in multiple spots (top, middle, bottom for width; left, middle, right for height) to account for any slight inconsistencies in the cabinet frame.

- Determine Overlay/Inset: Decide on your desired door overlay (how much the door overlaps the cabinet opening) or if you’re building inset doors (which sit flush within the opening). For standard full-overlay cabinets, I typically add a 1-inch overlay (meaning the door will be 1 inch wider and 1 inch taller than the opening, providing a 1/2-inch overlap on all sides).

- Create a Comprehensive Cutting List: Based on your door dimensions and chosen style (e.g., Shaker rail-and-stile width), calculate the exact length and width of every single piece of wood you’ll need: stiles, rails, and the center panel.

- Account for Saw Blade Kerf: Remember to factor in the thickness of your saw blade (kerf) when making multiple cuts from a single board to ensure your measurements remain accurate for subsequent pieces.

- Mark Wood Grain Direction: For aesthetic consistency and structural integrity, always mark the desired grain direction on your cutting list and on the wood itself, especially for rails and stiles.

- Double-Check All Measurements: Before making any cuts, review your entire cutting list and door dimensions one final time. It’s better to catch an error now than after the wood is cut.

Critical Tools Needed for Precision Measurement and Planning:

- Quality Measuring Tape: A reliable, clearly marked tape measure is non-negotiable. Look for one with a stiff blade that extends far without bending.

- Carpenter’s Square or Combination Square: Essential for marking perfectly square lines and verifying the squareness of your cabinet openings and initial cuts.

- Sharp Pencil: A fine-tipped, sharp pencil allows for precise, easily visible markings on your wood.

- Calculator: For quickly and accurately performing all necessary additions, subtractions, and dimension calculations for your cutting list.

- Note Paper and Clipboard: To meticulously record all your measurements, cutting lists, and any specific notes for each door.

- Story Stick (Optional but Recommended): A piece of scrap wood marked with exact dimensions and offsets can be invaluable for repetitive measurements, eliminating errors.

Step 2: Material Selection and Cutting – Choosing the Right Wood

I learned early on that choosing the right lumber is perhaps the most critical factor determining the success or failure of a cabinet door project. My extensive experience consistently shows that selecting straight, properly dried, and defect-free lumber significantly reduces problems like warping, twisting, and cracking down the line. Each board requires careful, thorough inspection for hidden defects such as knots, checks, splits, or areas of irregular grain that could compromise the final door’s structural integrity or appearance. I always make it a point to buy extra material, understanding that some pieces might reveal subtle flaws or unexpected grain patterns during the cutting process. Furthermore, the wood’s moisture content is paramount; I meticulously check this with a reliable moisture meter before starting any work, aiming for levels below 12% to prevent future movement and instability.

Detailed Material Assessment for Optimal Quality:

- Examine Boards for Knots and Splits: Avoid large or loose knots, and any visible splits or cracks that indicate structural weakness.

- Look for Straight-Grain Patterns: Opt for boards with long, straight grain lines as these are less prone to warping and twisting. Avoid wild, swirling grain patterns for door frames.

- Check Both Faces for Cupping and Bowing: Lay boards flat and eye down their length and width to detect any cupping (cross-grain curve) or bowing (longitudinal curve).

- Test Wood Density with Thumbnail: A simple test: press your thumbnail into the end grain. Harder woods will resist indentation more, indicating good density.

- Verify Moisture Levels Below 12%: Use a digital moisture meter to ensure the wood is adequately dried. High moisture content will lead to significant movement after assembly.

- Sort Boards by Grain Pattern and Color: Group similar-looking boards together for consistent appearance across all doors, especially for stain-grade projects.

Initial Cutting Process: From Rough Lumber to Precise Pieces

My cutting process always begins by rough-cutting pieces slightly oversized, typically by an inch or two in length and a quarter-inch in width. This extra dimension allows for final, precise trimming to exact dimensions in subsequent steps, ensuring perfectly square and clean edges. Each cut follows a specific, methodical order to maintain efficiency and minimize waste, starting with the longest pieces and working down. I mark all pieces clearly with their intended location (e.g., “Left Stiles,” “Top Rail – Door 1”) to avoid any confusion during assembly. Maintaining a clean and organized workspace during cutting is crucial; it not only enhances safety but also prevents costly mistakes and speeds up the workflow.

Strategic Cutting Steps for Efficiency and Accuracy:

- Cut All Stiles (Vertical Pieces) First: Rip and cross-cut your stiles to their rough dimensions first. This establishes your main frame components.

- Match Grain Patterns for Rails (Horizontal Pieces): Carefully select boards for rails that complement the grain of your stiles for a harmonious look, then rough-cut them to length.

- Size Center Panels Slightly Smaller: Cut your center panels to their rough width and length. Remember they need to “float” within the frame, so they will be slightly smaller than the overall frame opening.

- Label Each Piece with Location: Use a pencil to clearly label each rough-cut piece with its corresponding door number and component type (e.g., “D1-LS” for Door 1 Left Stile).

- Stack Similar Pieces Together: Keep your workspace tidy by stacking stiles, rails, and panels separately and neatly.

- Keep Offcuts for Future Projects: Don’t discard all small offcuts immediately; they can be useful for test pieces, shims, or smaller projects later.

Things I’ve Learned Through Years of Cutting:

- Sharp Blades Make Cleaner, Safer Cuts: Dull blades cause tearout, require more force, and increase the risk of kickback. Always use a sharp, appropriate blade for the job.

- Take Breaks to Maintain Accuracy: Fatigue leads to mistakes. Step away from the saw periodically to rest and refocus, especially during long cutting sessions.

- Check Measurements Between Cuts: Don’t assume. Re-measure your stock before each critical cut to ensure you’re working with the correct dimensions.

- Keep the Work Area Clean and Clear: Sawdust accumulation and cluttered surfaces are safety hazards and can obstruct accurate measurements and cuts.

- Use Push Sticks and Safety Gear: Always prioritize safety. Use push sticks for narrow cuts and wear eye and ear protection.

- Understand Grain Direction: Plan your cuts to minimize tearout, especially on cross-grain cuts, by using a sacrificial fence or scoring the cut line.

Step 3: Frame Construction and Panel Preparation – Building Strength

I’ve learned that the integrity of the frame assembly is the single most important factor determining a cabinet door’s strength, stability, and longevity. This stage demands the utmost attention to detail and absolute precision in every measurement and cut. Before any glue is introduced to the wood, I invest significant time meticulously checking each joint. The way these individual pieces fit together at this stage will directly impact how the door performs, resists warping, and maintains its squareness for many years to come. Every joint is carefully tested dry, often multiple times, to ensure a perfect, gap-free fit before permanent assembly ever begins.

Creating Rail and Stile Joints: Precision Joinery

For most DIY cabinet doors, I prefer using a matched rail and stile router bit set (often called “cope and stick” bits) for creating robust and attractive joints. I meticulously set up my router table, ensuring the bit height and fence settings are dialed in precisely. Each piece—first the stiles, then the rails—is run through in a specific, consistent order to maintain grain alignment and ensure matching profiles. Crucially, I always use scrap test pieces to verify the router bit height and fence settings before cutting any actual door components. Safety is paramount during this often noisy and dusty process; I always wear proper eye and ear protection. I’ve found that multiple light passes through the router, rather than a single heavy cut, produce much cleaner, tear-out-free joints.

Detailed Assembly Steps for Flawless Joints:

- Set Up Router with Test Pieces First: Never run your actual door parts without making test cuts on scrap wood to fine-tune your router bit height and fence position for a perfect fit.

- Cut All Matching Grooves in Stiles: Using the slot-cutting bit (or the first part of your cope and stick set), run the inside edge of all your vertical stiles to create the groove for the panel and the first half of the joint profile.

- Route Rail Ends for Proper Joint Fit: Switch to the cope bit (or the second part of your cope and stick set) and route the ends of your horizontal rails. Ensure these pieces are held securely and passed consistently for uniform profiles.

- Test Fit Each Joint Carefully: Dry-fit every rail-to-stile joint. They should fit snugly without being forced, and there should be no gaps visible at the shoulders of the joint.

- Mark Mating Pieces to Maintain Alignment: Use a small, subtle pencil mark or a piece of painter’s tape to indicate which rail goes with which stile, and their orientation, to ensure perfect alignment during glue-up.

- Clean All Joints Thoroughly: Use a brush or compressed air to remove any dust or small wood fibers from the joint profiles. Even tiny debris can prevent a tight, strong glue joint.

Critical Joint Tips for Strength and Aesthetics:

- Check Depth Consistency: Ensure your router bits are consistently cutting to the same depth across all pieces for uniform joints.

- Verify Square Cuts on Rail Ends: Any angle deviation on the rail ends will result in a gapped joint when assembled.

- Test Fit Everything Dry: This cannot be stressed enough. A dry fit allows you to catch and correct issues before glue makes them permanent.

- Keep Pieces Organized: Lay out all your stiles, rails, and panels for each door in order to avoid confusion during assembly.

- Clean Dust Between Tests: Dust can give a false impression of a tight fit.

- Listen for Proper Cutting Sounds: A smooth, consistent hum from your router indicates a good cut; straining or chattering sounds suggest issues with feed rate, bit sharpness, or setup.

- Use Featherboards: These hold workpieces firmly against the fence and table, ensuring consistent cuts and enhancing safety.

Things I’ve Learned Through Experience with Joinery:

- Rushing Joints Leads to Gaps: Patience is rewarded with tight, invisible joints. Haste nearly always results in visible imperfections.

- Temperature and Humidity Affect Wood Movement: Be aware that wood can expand or contract slightly between cuts and assembly, especially in fluctuating environments.

- Grain Direction Matters for Strength: Always ensure the strongest grain direction is oriented correctly for load-bearing components like stiles.

- Even Pressure Prevents Tearout: Apply consistent, steady pressure when feeding wood through the router to prevent wood fibers from tearing out, especially at the end of a cut.

- Invest in Quality Bits: Cheap router bits quickly dull and produce inferior cuts. High-quality carbide bits stay sharp longer and yield better results.

Step 4: Panel Fitting and Final Assembly – Bringing It All Together

After years of building countless doors, this stage remains my absolute favorite – it’s the moment when all the meticulously crafted pieces finally come together, transforming into a complete, functional unit. Before any glue is applied, I carefully lay out all components for each door in their final intended position. The center panel, in particular, requires special attention to ensure there’s adequate allowance for seasonal wood movement. The ambient temperature and humidity levels in my workshop significantly influence how snugly the panel should fit, requiring a delicate balance to prevent future cracking or bowing. This step above all others demands patience; rushing through it invariably leads to misaligned doors, compromised squareness, and ultimately, dissatisfaction with the final product. A perfect, gap-free assembly is within reach with careful attention.

Panel Installation Process: The Floating Panel Principle

The cardinal rule for traditional frame-and-panel doors is that the center panel must “float” freely within the grooves of the frame. This allows the panel to expand and contract with changes in humidity without putting stress on the surrounding frame, which could otherwise lead to cracks. To maintain even gaps around the panel and prevent rattling, I often use small rubber spacers (like “space balls”) or tiny dabs of silicone at the center points of the panel edges. Each panel is checked for squareness before the frame assembly begins, and its grain direction is oriented to minimize visible movement during seasonal changes. I always perform a complete dry fit of the entire door at least twice, carefully checking for squareness and panel movement, before committing to the final glue-up.

Detailed Assembly Steps for a Strong, Stable Door:

- Clean All Grooves Thoroughly: Use a small brush or compressed air to ensure the grooves in the stiles and rails are free of sawdust, glue squeeze-out from test fits, or other debris.

- Test Panel Fit in All Directions: Insert the panel into the grooves of your dry-fitted frame. It should slide in easily with a small amount of play, indicating proper allowance for expansion.

- Apply Glue Only to Rail and Stile Joints: Crucially, only apply a thin, even bead of wood glue to the cope-and-stick profiles (or mortise and tenon shoulders) where the rails meet the stiles.

- Keep Glue Away from the Floating Panel: Do NOT apply glue into the panel grooves or directly to the edges of the center panel. This would “lock” the panel in place and prevent it from moving, leading to cracks.

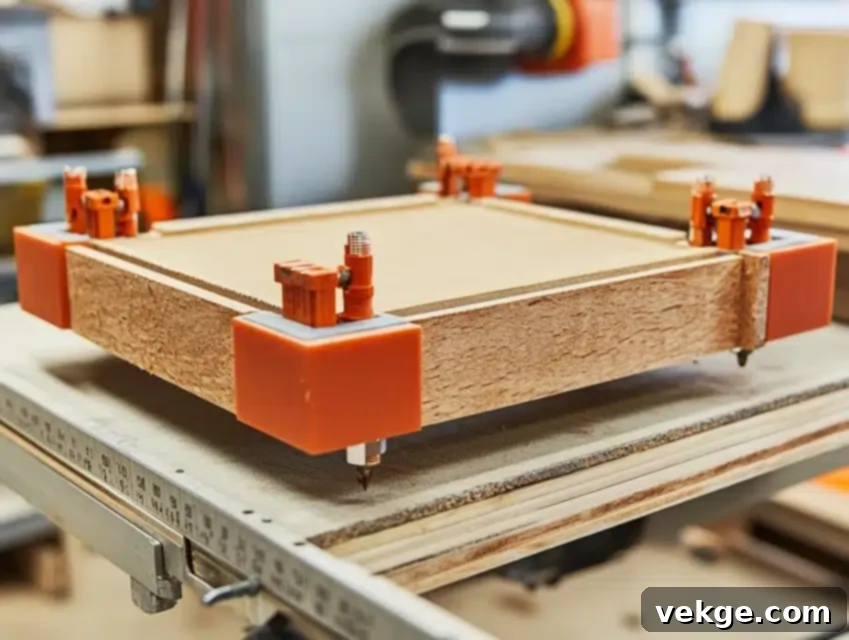

- Assemble and Use Corner Clamps for Square Alignment: Immediately after applying glue, assemble the frame around the panel. Use specialized corner clamps or conventional bar clamps with corner blocks to pull the joints tight and ensure the frame is perfectly square.

- Check Diagonal Measurements Repeatedly: Once clamped, measure the door diagonally from corner to corner in both directions. These measurements must be identical for the door to be truly square. Adjust clamps as needed.

Critical Clamping Process for a Durable Door:

- Start with Corner Clamps or Pinch Dogs: These are excellent for pulling joints tight and ensuring initial squareness.

- Add Parallel Clamps Gradually: Apply additional bar or parallel clamps across the width and length of the door, distributing pressure evenly. Avoid over-tightening.

- Check for Squareness Frequently: Continually monitor the diagonal measurements as you apply and adjust clamps.

- Wipe Excess Glue Immediately: Use a damp rag to clean up any glue squeeze-out from the joints and surfaces. Dried glue is incredibly difficult to sand away and can prevent stain from absorbing evenly.

- Allow Proper Drying Time: Follow the glue manufacturer’s recommendations for clamping and full cure times. Rushing this step compromises joint strength.

- Maintain Even Pressure: Ensure clamps are applying consistent, firm pressure across all joints. Uneven pressure can lead to subtle warps or gaps.

Things I’ve Learned About Glue-Up and Clamping:

- Panel Movement is Natural and Essential: Embrace the floating panel. It’s a design feature, not a flaw, that ensures your door’s longevity.

- Over-Clamping Causes Problems: Too much pressure can squeeze out too much glue, starve the joint, or even dent the wood. Aim for firm, but not excessive, pressure.

- Glue Squeeze-Out Stains Wood: Especially with stain-grade wood, invisible dried glue residue will prevent stain absorption, leaving light patches. Clean thoroughly.

- Room Temperature Affects Drying: Cooler temperatures extend glue drying times. Ensure your workshop is within the recommended temperature range for your adhesive.

- Take Breaks Between Doors: Gluing multiple doors can be exhausting and lead to errors. Pace yourself.

- Prepare for Glue-Up: Have all your clamps, glue, square, and cleaning supplies ready and within reach before you start applying glue.

Crucial Assembly Tips for Success:

- Work on a Flat Surface: A flat, level workbench is essential for assembling square, un-twisted doors.

- Keep Cleaning Supplies Ready: Rags, a bucket of water, and a scraper should be at hand for immediate glue cleanup.

- Have All Clamps Prepared: Set out the right number and type of clamps you’ll need for each door before applying glue.

- Check Measurements Constantly: From dry-fitting to final clamping, continuously verify squareness and dimensions.

Step 5: Surface Preparation and Finishing – The Art of Perfection

This stage is where raw, assembled wood truly transforms into beautiful, durable cabinet doors. I’ve learned, through countless projects, that proper surface preparation is the absolute determinant of the final finish quality. It’s not just about sanding; it’s about creating a perfectly smooth, blemish-free canvas. Each door receives multiple sanding passes, systematically working through progressively finer grits. The time and effort invested here are unequivocally evident in every reflection, every tactile sensation of the finished surface, and the longevity of the protective coating. Furthermore, meticulous dust control becomes critically important at this stage to achieve truly professional-level results, preventing tiny particles from embedding in your finish.

Initial Surface Preparation: Seeking Perfection

I always begin with a thorough, detailed inspection of the entire door surface under strong, directional lighting. This helps reveal any imperfections that might be missed in ambient light. Any lingering glue residue, even seemingly tiny specks, must be completely scraped away or carefully chiseled before sanding begins, as dried glue will prevent stain or paint from adhering evenly. Each surface needs to receive consistent, even sanding patterns to avoid swirl marks, unevenness, or “dish-outs.” I pay particular attention to ensuring smooth transitions between the rails and stiles, as any slight offset will become glaringly obvious once a finish is applied. Small flaws that seem negligible in raw wood will be magnified exponentially by the finish.

Detailed Sanding Steps for a Flawless Foundation:

- Begin with 80-Grit for Heavy Cleanup (if needed): If there are significant surface imperfections, deep scratches, or stubborn glue spots, start with a coarser 80-grit sandpaper on an orbital sander. Use sparingly and move quickly.

- Progress Through 120-Grit Evenly: Move to 120-grit sandpaper. This grit removes the scratches from the coarser paper and starts to smooth the surface. Apply even pressure and cover all surfaces uniformly.

- Use 180-Grit for Final Smoothing Before Finishing: For most finishes (especially paint), 180-grit is sufficient. For stain-grade wood, you might go up to 220-grit. Ensure all previous grit scratches are eliminated.

- Sand Edges are Slightly Softer: Use a sanding block or by hand to gently break (round over) the sharp edges of the door. This makes them more comfortable to touch and helps the finish adhere better.

- Remove All Dust Between Grits: After each grit, thoroughly clean the door with a vacuum, then a tack cloth or compressed air. Any remaining dust will scratch the surface with the next finer grit.

- Check the Surface with Bright, Raking Light: Hold a bright light at a low angle across the surface. This “raking light” will highlight any remaining scratches, swirl marks, or imperfections you might have missed.

The Finishing Process: Protection and Beauty:

- Apply Wood Conditioner First (for stain): If you’re staining, a pre-stain wood conditioner helps ensure more even stain absorption, especially on woods like pine or maple that can be blotchy.

- Apply Finish in Thin, Even Coats: Whether paint, stain, or clear coat, apply multiple thin coats rather than one thick one. This provides better adhesion and a smoother finish.

- Let Each Coat Dry Completely: Adhere strictly to the manufacturer’s recommended drying times between coats. Rushing this leads to sticky finishes and poor adhesion.

- Sand Lightly Between Coats (if recommended): For clear coats and paint, a very light sanding with 220-320 grit sandpaper between coats (called “scuff sanding”) improves adhesion and smoothness. Clean dust thoroughly.

- Keep Room Dust-Free and Well-Ventilated: Work in a clean, dust-free environment with good airflow to prevent dust nibs from settling in the wet finish and to safely dissipate fumes.

- Check for Runs or Sags Immediately: As you apply the finish, continuously inspect for drips, runs, or sags. Address them quickly with your brush or roller before they dry.

Things I’ve Learned About Finishing:

- Rushing Causes Visible Flaws: Patience is your greatest ally in achieving a flawless finish. Every skipped step or rushed application will show.

- Temperature Affects Drying and Flow: Ideal finishing temperatures are typically between 65-75°F (18-24°C). Too cold, and the finish dries slowly; too hot, and it dries too fast, leading to brush marks.

- Humidity Changes Finish Time and Behavior: High humidity can extend drying times and cause some water-based finishes to “blush” or become cloudy.

- Light Affects Color Choices and Visibility of Flaws: Always evaluate your finish color in the actual lighting conditions of your home. Use good lighting while applying finish to spot imperfections.

- Patience Produces the Best Results: There are no shortcuts to a truly professional, durable finish. Take your time, follow instructions, and enjoy the process.

- Cleanliness is Next to Godliness: A clean shop, clean tools, and clean hands are essential for a perfect finish.

Final Inspection Points After Finishing:

- Check All Surfaces for Smoothness: Run your hand across every part of the door. It should feel silky smooth, free of any roughness or bumps.

- Verify Consistent Color and Sheen: Ensure the finish is uniform in color (if stained) and sheen across the entire door, with no dull spots or streaking.

- Look for Dust Nibs: Under strong light, examine the surface for any tiny bumps caused by dust settling in the wet finish. These can sometimes be polished out carefully.

- Test Finish Hardness: Gently press a fingernail into an inconspicuous area (like the back edge). The finish should be hard and resistant to indentation, indicating it’s fully cured.

Step 6: Hardware Installation and Mounting – The Final Touch

Installing hardware correctly is the critical final step that ensures your beautifully crafted doors function smoothly, silently, and reliably for many years. This stage demands absolute precision in measurements and extreme care in drilling. To achieve consistent placement across all doors, I always create robust templates for hinge cups and handle/pull locations. Each hinge location gets marked and meticulously checked twice before any drilling commences. Taking ample time here to ensure everything is perfectly aligned and drilled correctly prevents costly mistakes, the need for wood filler, and frustrating readjustments down the line. A well-installed door operates effortlessly and looks professionally done.

Hinge Installation Process: Ensuring Smooth Operation

I start by setting up a dedicated hinge installation station, typically a clear, padded area on my workbench, to protect the newly finished doors. Every measurement for hinge placement is verified against my master template for consistency. The depth of the drill bit, especially for concealed European-style hinges, is crucial; it determines how flush the hinge cup sits against the wood and prevents drilling through the front of the door. Furthermore, each screw hole requires a properly sized pilot drill to prevent the wood from splitting, particularly in hardwoods. Before mounting the doors to the cabinet, I test the hinge movement on the door itself to ensure smooth, unhindered articulation.

Detailed Hardware Installation Steps:

- Mark All Hinge Locations Precisely: Use a template or a combination square to accurately mark the exact centers for your hinge cups and screw holes on the back of each door. Consistency is key across all doors.

- Create Pilot Holes with Proper Depth: Using a drill bit slightly smaller than your screws, drill pilot holes. For concealed hinges, use a Forstner bit with a depth stop to drill the hinge cup recesses to the correct depth.

- Check Hinge Fit Before Final Mounting: Place the hinges into their recesses or against the door surface. Ensure they sit flush and are oriented correctly before inserting any screws.

- Install Soft-Close Mechanisms (if needed): If your chosen hinges require separate soft-close mechanisms, install them according to the manufacturer’s instructions.

- Test Swing Motion Before Handles: Attach the doors to the cabinet frames. Open and close each door several times to check for any binding or rubbing before installing handles or pulls.

- Verify All Screws Are Tight but Not Overtightened: Secure all hinge screws firmly. Overtightening can strip screw holes or crack the wood.

Handle and Pull Installation: The User Interface:

- Measure Placement Carefully: Decide on the consistent height and horizontal placement for all handles or pulls. Measure from the top/bottom and side edges of the door.

- Use Templates for Consistency: A simple jig or template made from scrap wood ensures all handles are installed at the exact same position, which is critical for a professional look.

- Drill Straight Through: Use a drill press or a very steady hand with a handheld drill, ensuring the bit goes straight through the door to avoid angled holes.

- Support Back While Drilling: Place a scrap block of wood behind the door where you are drilling to prevent tearout as the drill bit exits the wood.

- Test Handle Security: After installation, give each handle or pull a gentle tug to ensure it is firmly attached and doesn’t wiggle.

- Check Alignment Visually: Step back and visually inspect all handles/pulls to ensure they are perfectly aligned with each other and the door’s lines.

Things I’ve Learned About Hardware Installation:

- Different Hinges Need Different Depths: Always read the instructions for your specific hinge type to determine the correct cup depth and bore diameter.

- Wood Density Affects Screw Grip: In softer woods, screws can strip more easily; in harder woods, pilot holes are even more crucial to prevent splitting.

- A Template Saves Enormous Time and Ensures Consistency: This is a game-changer for projects with multiple doors. Make one, and use it diligently.

- Keep Spare Hinges and Screws Handy: Mistakes happen. Having a few extra pieces of hardware can prevent delays.

- Test Motion Frequently: Periodically check door swing and alignment during the installation process, not just at the very end.

- Don’t Force Screws: If a screw is difficult to drive, the pilot hole might be too small. Remove it, enlarge the pilot hole slightly, and try again.

Final Adjustments for Perfect Operation:

- Check Door Gaps: Ensure consistent, even gaps (typically 1/8 inch or 3mm) between all doors and surrounding cabinet frames.

- Adjust Hinge Screws: Most modern hinges have adjustment screws to fine-tune door position (in/out, up/down, left/right). Make small, incremental adjustments.

- Test Closing Action: Confirm doors close completely and softly. If using soft-close, ensure it functions as intended.

- Verify Handle Alignment: Double-check that all handles and pulls are perfectly straight and level, both individually and in relation to neighboring doors.

Why Choose to Build Your Own Cabinet Doors?

My clients often ask why they should invest their time and effort in building cabinet doors themselves rather than simply purchasing them. The compelling answers become undeniably clear once they see the final product and experience the benefits firsthand:

- Complete Control Over Wood Choice and Quality: When you build, you select every piece of lumber. This means you can hand-pick the finest grades of wood, choose specific grain patterns, and avoid defects that might be present in mass-produced options, ensuring a superior base material for your project.

- Perfect Size Matching for Odd-Sized Cabinets: Renovations or older homes often have unique cabinet openings that don’t conform to standard door sizes. Building your own allows you to create doors that fit perfectly, eliminating unsightly gaps or the need for expensive custom orders from manufacturers.

- Substantial Cost Savings on Large Projects: The material cost for a DIY cabinet door is significantly less than the retail price of a pre-made door, especially for a whole kitchen. These savings can be considerable, often ranging from 40% to 60%, freeing up budget for other aspects of your renovation.

- Ability to Match Existing Woodwork Exactly: If you’re only replacing a few doors or adding new cabinets to an existing setup, building your own ensures you can precisely match the wood species, finish, and style of your current cabinetry, creating a cohesive look that store-bought options rarely achieve.

- Pride in Creating Something Lasting and Beautiful: There’s an immense sense of accomplishment and satisfaction that comes from seeing a perfectly crafted, functional piece of your home that you built with your own hands. This personal connection and pride in your work are truly invaluable.

- Custom Design and Personalization: Beyond standard styles, building allows for unique design elements, custom profiles, or specific details that truly reflect your personal taste and complement your home’s unique character, making your kitchen one-of-a-kind.

Common Cabinet Door Issues and Effective Solutions

Even with the best planning, woodworking can present challenges. My experience has taught me to anticipate common issues and develop practical solutions.

1. Understanding Wood Movement and Door Issues

What might appear to be a perfectly straight door today can, unfortunately, warp or bow tomorrow. I’ve learned that wood is a living material; its movement follows predictable patterns based on grain direction, density, and environmental changes. Significant fluctuations in temperature and humidity affect every door differently, causing expansion and contraction. Early detection of these movements – observing slight changes in gaps or flatness – is crucial, as it allows for minor adjustments before issues become serious and permanent. Regular inspection helps catch small problems before they escalate into major repairs.

2. Measurement Mishaps: The Most Common DIY Pitfall

The most frequent and frustrating error I encounter, particularly with beginners, involves overlooking critical overlay measurements. A single wrong dimension can multiply its error across an entire kitchen project, leading to uneven gaps, doors that clash, or hardware that won’t align. Many beginners also forget to account for hinge spacing and the necessary small clearances around doors in their calculations. The consistent use of well-made templates for repetitive measurements virtually eliminates most measurement errors before a single piece of wood is cut. For ultimate precision, digital calipers provide a level of accuracy that standard tape measures simply cannot match, especially for joinery measurements.

3. Sanding Secrets and Avoiding Mistakes

Over-sanding edges, especially on frame-and-panel doors, is one of the hardest mistakes to correct, as it subtly rounds over crisp lines, changing the door’s profile. I learned early on to clearly mark the original dimensions and profiles before starting any significant sanding. Using dedicated sanding blocks, rather than free-hand sanding, is essential for maintaining crisp, square edges and flat surfaces. Progressing through a sequence of increasingly finer grits, rather than aggressively sanding with a single grit, produces much smoother and more professional results. Regularly checking the sanded surface with a straight edge and strong raking light helps catch subtle imperfections and unevenness early.

4. Gap Problems: Troubleshooting Uneven Spaces

Uneven gaps around cabinet doors often signal deeper underlying installation or construction issues. My first step is always to check the diagonal measurements of the door frame itself to identify if it’s twisted or out of square. For minor gap discrepancies, hinge adjustment usually provides a quick and effective solution, as most modern hinges offer multiple directions of adjustment. It’s important to remember that some small, seasonal gaps may appear and disappear with wood movement due to changes in humidity; these are often natural and unavoidable. Keeping detailed notes and photos of gap patterns over time can help differentiate between a construction error and natural wood behavior.

5. Hardware Solutions and Maintenance

Loose hinges are a primary cause of persistent door alignment issues and sagging. When screws become loose, I typically remove them and replace them with slightly larger gauge or longer screws to ensure a better grip in the wood. For particularly heavy or oversized doors, adding a third hinge in the middle can significantly improve support and help the door maintain its alignment over time. Magnetic catches are an excellent solution for doors that tend to swing open slightly on their own. Finally, ensuring proper hinge spacing during installation is crucial for preventing long-term stress problems on both the door and the cabinet frame, promoting smooth and lasting operation.

Maintenance Schedule for Your DIY Cabinet Doors

To ensure your custom-built cabinet doors remain beautiful and functional for years, a simple, consistent maintenance routine is key. This schedule helps address minor issues before they become major problems and preserves the integrity of your hard work.

| Frequency | Tasks | Details |

|---|---|---|

| Monthly | Wipe down surfaces | Use a soft, damp (not wet) cloth to gently remove dust, grime, and fingerprints. Avoid harsh chemicals that can damage the finish. |

| Check hinge movement | Open and close each door. Ensure smooth operation and listen for any squeaks or stiffness. A drop of lubricant designed for hinges can resolve minor issues. | |

| Note any new issues | Perform a quick visual inspection. Look for new scratches, dents, small chips in the finish, or any loose hardware components. Early detection is vital. | |

| Quarterly | Deep clean all surfaces | Use a gentle, pH-neutral cleaner specifically designed for finished wood or cabinetry. Apply with a soft cloth and wipe dry immediately to prevent water damage. |

| Tighten loose hardware | Using a screwdriver, gently tighten any screws on hinges, handles, or pulls that feel loose. Be careful not to overtighten and strip the screw holes. | |

| Adjust for seasonal changes | Check door alignment, especially during periods of significant humidity shifts (e.g., summer to winter). Make small adjustments to hinge screws as needed to maintain even gaps. | |

| Annually | Refinish worn areas | Inspect high-traffic areas (around handles, bottom edges) for finish wear. Lightly sand affected spots and apply a fresh, thin coat of the original finish to protect the wood. |

| Replace damaged hardware | Swap out any hinges, handles, or catches that are broken, corroded, or no longer functioning correctly. This prevents further damage to the door or cabinet. | |

| Complete alignment check | Perform a comprehensive check of all doors, ensuring they close evenly, are perfectly flush when closed, and have consistent gaps all around. Adjust all hinges as necessary for optimal performance. |

Conclusion: Embrace the Journey of Woodworking

After guiding you through my comprehensive door-building process, remember that perfection in woodworking is less about innate talent and more about consistent practice and continuous learning. Every master craftsperson, myself included, started with their very first door, learning invaluable lessons from each subsequent project. The skills you develop building cabinet doors – precision measuring, careful cutting, meticulous assembly, and thoughtful finishing – are highly transferable and will serve you well in countless other woodworking endeavors.

The profound satisfaction that comes from closing a cabinet door you built yourself, knowing its quality and durability, makes every moment of effort worthwhile. It’s not just a door; it’s a testament to your skill and dedication. Keep these key points firmly in mind as you embark on your own projects:

- Take Time with Measurements: Precision at the outset prevents costly errors later. “Measure twice, cut once” is an unbreakable rule.

- Stay Organized Throughout the Process: A tidy workspace and labeled components streamline your workflow and reduce mistakes.

- Learn from Each Challenge: View every setback as an opportunity to refine your techniques and deepen your understanding of the craft.

- Document Successful Techniques: Keep a notebook of your methods, settings, and solutions. This personal reference will be invaluable for future projects.

- Maintain Tools Properly: Sharp, well-calibrated tools are safer and produce superior results.

- Share Knowledge with Others: The woodworking community thrives on shared experience. Help others and learn from their insights.

Most importantly, allow yourself to genuinely enjoy the creative process. Cabinet doors might appear to be simple functional components, but they offer endless opportunities for artistic expression, skill development, and a deep connection to the materials you work with. With the right tools, unwavering attention to detail, and a healthy dose of patience, you will undoubtedly create doors that not only enhance the beauty of your home but also serve you flawlessly for many years to come.

Frequently Asked Questions About Building Cabinet Doors

What Are the Easiest Methods to Make Cabinet Doors at Home?

From my extensive experience, slab-style doors offer the simplest and most accessible starting point for home DIYers. They involve taking a single, good-quality piece of plywood or MDF, cutting it to size with straight edges, and then applying iron-on or pre-glued edge banding for a clean, finished appearance. This minimizes complex joinery. Shaker-style doors provide another excellent beginner-friendly option, requiring only basic tools like a table saw or circular saw with a guide, and straightforward frame-and-panel construction techniques. I highly recommend starting with a single door, perhaps for a utility cabinet or a small bathroom vanity, to practice your techniques and build confidence before tackling larger, more visible projects like a full kitchen.

What Materials and Tools Do I Need to Build Cabinet Doors?

To begin building cabinet doors, essential tools typically include a reliable measuring tape, a combination square, a sharp pencil, a circular saw (with a guide for straight cuts) or a table saw for more precision, a drill/driver for pilot holes and hardware, a set of clamps for assembly, and various sanding supplies (sander and sandpaper). For materials, always start with quality lumber; pine is an economical choice if you plan to paint your doors, while hardwoods like maple, oak, or cherry are excellent for staining. You’ll also need strong wood glue, appropriate screws for hardware, and your chosen finish (paint, stain, clear coat). I strongly suggest buying a bit of extra material for practice cuts and to account for any mistakes. A basic set of tools for cabinet doors can be acquired for around $200-$300 if you’re starting from scratch, making it a very accessible hobby.

Can I Make Cabinet Doors without Advanced Woodworking Skills or Specialized Tools?

Absolutely! My own journey started with very basic tools and simple designs, proving that advanced skills and expensive specialized equipment are not prerequisites for getting started. For instance, slab doors require only precise straight cuts and careful measuring. While specialized tools like router tables with rail and stile bit sets certainly make the work faster and often yield more refined results, they are not essential for many basic styles. For occasional use, consider borrowing or renting tools like a router if you’re not ready to invest. Initially, your focus should be on developing accuracy, patience, and attention to detail rather than mastering complex advanced techniques. Many high-quality doors can be made with surprisingly simple setups.

How Much Does It Cost to Build Cabinet Doors versus Buying Them?

Building your own cabinet doors typically offers significant cost savings, often ranging from 40% to 60% compared to purchasing comparable pre-made doors from a retail supplier or custom shop. For example, a standard 24″x30″ Shaker-style door might cost me approximately $30-$40 in raw materials (lumber, glue, and sandpaper), whereas a similar pre-made door could easily retail for $100 or more, not including shipping or custom sizing fees. It’s crucial, however, to factor in the initial cost of tools if you are starting without any. The savings become even more substantial when you need multiple doors, or especially for custom sizes, which often incur premium prices when bought ready-made. The more doors you build, the greater the per-door savings.

What Are the Different Styles of Cabinet Doors I Can Make Myself?

Through my various projects, I’ve found that several cabinet door styles are quite achievable for the dedicated DIYer, each offering a distinct aesthetic:

- Slab Doors: These are the simplest, consisting of a single flat panel, ideal for modern, minimalist designs and perfect for beginners.

- Shaker Style: A classic, timeless design featuring a flat center panel surrounded by a square-edged frame (stiles and rails). This offers a moderate difficulty level and is incredibly versatile.

- Flat Panel (or Recessed Panel): Similar to Shaker, but often allows for slightly more decorative inner profiles on the frame, providing a modern yet slightly more refined appearance. Construction is straightforward.

- Glass Panel: These doors incorporate a glass insert (clear, frosted, or patterned) into a frame, adding elegance and allowing for display. They require careful measuring for the glass opening but are generally manageable.

- Beadboard: Featuring a center panel with vertical grooves, mimicking traditional beadboard paneling. This style offers a charming farmhouse or cottage aesthetic but requires more detailed work for the panel itself.

I always recommend starting with simpler styles like slab or Shaker and gradually progressing to more complex designs as your woodworking skills and confidence develop.