The Ultimate Guide to Stair Stringers: Building Safe, Stable, and Stylish Deck Stairs

Embarking on a deck construction project can be an exciting endeavor, transforming your outdoor living space. However, many homeowners often find themselves navigating the complexities of stair design and construction, particularly when it comes to understanding and implementing stair stringers. These fundamental components are not just parts of a staircase; they are the very foundation upon which the safety and stability of your entire stair structure rest.

At first glance, stair stringers might seem like just another piece of lumber, but their role is far more critical. Misunderstandings or miscalculations regarding these key elements can lead to wobbly, unsafe stairs that not only fail to meet building codes but also pose a significant risk to anyone using them. We understand these challenges, and our goal is to demystify the process, equipping you with the knowledge needed to build stairs that are both secure and aesthetically pleasing.

This comprehensive guide will delve deep into the world of stair stringers. We’ll clarify what they are, explain why they are absolutely indispensable for your deck or any staircase, and walk you through the essential steps to get them right. From selecting the most suitable materials that can withstand the elements to mastering the precise calculations required for a perfect rise and run, we’ve got you covered. You’ll also learn about different types of stringers, their unique benefits, and practical tips for installation and maintenance.

By the time you finish reading, you’ll not only have a clear, confident understanding of what stair stringers are but also possess the practical knowledge to confidently incorporate them into your next deck or home improvement project. Let’s step into the world of structural stair supports together and build something truly remarkable!

What Are Stair Stringers and Why Are They Crucial for Your Deck?

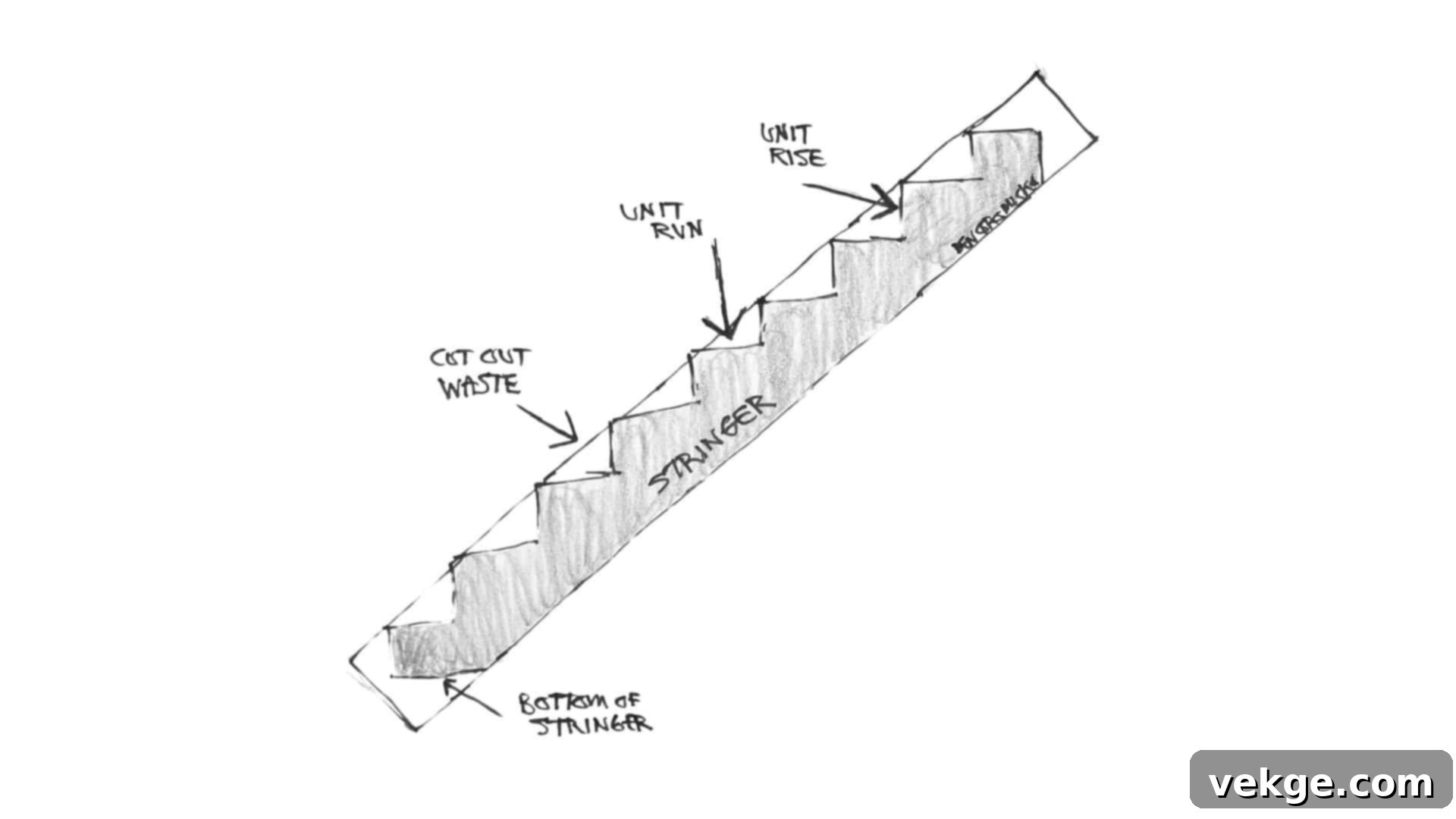

At their core, stair stringers are the angled, structural members that form the essential framework of a staircase. Picture them as the “bones” or the “backbone” of your stairs; they are what hold everything together. These robust components run diagonally from the top landing to the ground or lower landing, providing continuous support for the stair treads (where you step) and risers (the vertical part between steps).

Without properly designed and installed stair stringers, a staircase would simply not be able to function safely. They are engineered to bear the weight of people using the stairs, distributing this load evenly and preventing the treads from sagging, shifting, or collapsing. In essence, stringers ensure that your staircase remains stable, secure, and capable of withstanding the daily stresses of foot traffic. For deck stairs, which are exposed to the elements, the importance of durable and correctly installed stringers is even more pronounced, as they must endure weather fluctuations while maintaining structural integrity.

The Indispensable Role of Stair Stringers in Deck Construction

Understanding the purpose and critical importance of stair stringers goes beyond their basic definition. They are fundamental to three key aspects of any staircase: structural support, user safety, and compliance with local building regulations.

1. Structural Support: The Unseen Foundation of Your Steps

Stair stringers are the primary load-bearing elements of any staircase. Their design dictates the entire structural integrity. They are engineered to carry not only the static weight of the treads and risers themselves but also the dynamic load of people ascending and descending. When properly installed, these sturdy components effectively distribute weight from each step down to the foundation, preventing excessive flex, bending, or sagging that could compromise the stairs over time.

The strength and longevity of your deck stairs directly depend on the quality and correct installation of your stringers. Whether it’s a simple set of outdoor steps or a more elaborate multi-landing staircase, well-designed stringers ensure that your stairs can withstand years of use, extreme weather conditions, and heavy foot traffic without deteriorating prematurely. This robust support minimizes the need for frequent repairs and contributes significantly to the overall durability of your deck.

2. Safety Considerations: Preventing Accidents One Step at a Time

When it comes to stairs, safety is paramount, and this is where stair stringers play an absolutely critical role. A properly constructed stringer ensures that each step remains level, uniform in height (rise), and consistent in depth (run). This consistency is vital for preventing trips and falls, which are common hazards on poorly built or maintained stairs.

If stringers are improperly measured, cut, or made from inadequate materials, the results can be catastrophic. Uneven rises, wobbly treads, or steps that are not securely fastened can lead to serious accidents. For instance, a small variation in the height of a step can easily cause someone to misstep. Regular inspection of your stringers for signs of wear, rot, or looseness is also crucial, especially for outdoor deck stairs that are constantly exposed to moisture and temperature changes. Promptly addressing any issues, such as tightening loose fasteners or repairing damaged sections, is essential for maintaining a safe and reliable staircase.

3. Compliance with Building Codes: A Legal and Safety Requirement

Building stairs isn’t just about functionality; it’s also about adhering to established safety standards and regulations. Most municipalities and regions have strict building codes that govern staircase construction, and stair stringers are often at the heart of these requirements. These codes typically specify acceptable dimensions for tread depth and riser height, the minimum number of stringers required for a given stair width, the material specifications, and fastening methods.

Ignoring these building codes can have serious consequences. Non-compliant stairs can lead to fines, stop-work orders, or the costly requirement to dismantle and rebuild your entire staircase. More importantly, if someone is injured on non-code-compliant stairs, you could be held legally liable. It is always prudent to consult your local building department or a licensed contractor before starting any stair project. They can provide guidance on specific local requirements, ensuring your stringers and the entire staircase are not only safe for everyone but also fully compliant with all applicable regulations.

Exploring the Types of Stair Stringers for Your Deck Project

The world of stair stringers offers several design and structural options, each with its unique aesthetic and practical applications. When planning your deck stairs, understanding these main types — closed stringers, open stringers, and mono stringers — will help you choose the best fit for your project’s style, budget, and structural needs.

Closed Stringers: The Classic, Encased Look

Closed stringers, sometimes referred to as ‘routed’ or ‘housed’ stringers, are characterized by their ability to completely conceal the edges of the stair treads and risers. In this design, the treads and risers are typically fitted into grooves or dadoes cut directly into the stringer, creating a neat, box-like appearance. The stringers themselves form solid, unbroken side panels along the staircase.

You’ll often find closed stringers in traditional home interiors where a finished, refined look is desired. For deck stairs, they offer a very clean and robust appearance. A key advantage is the protection they offer to the edges of the treads and risers, shielding them from wear, impact, and weather exposure, which can be beneficial for outdoor applications.

- Pros: Provide a clean, elegant, and finished aesthetic; offer excellent protection for tread and riser edges; generally very sturdy.

- Cons: Can be more complex and time-consuming to fabricate and install due to precise routing requirements; potentially higher material and labor costs.

Open Stringers: The Exposed, Modern Appeal

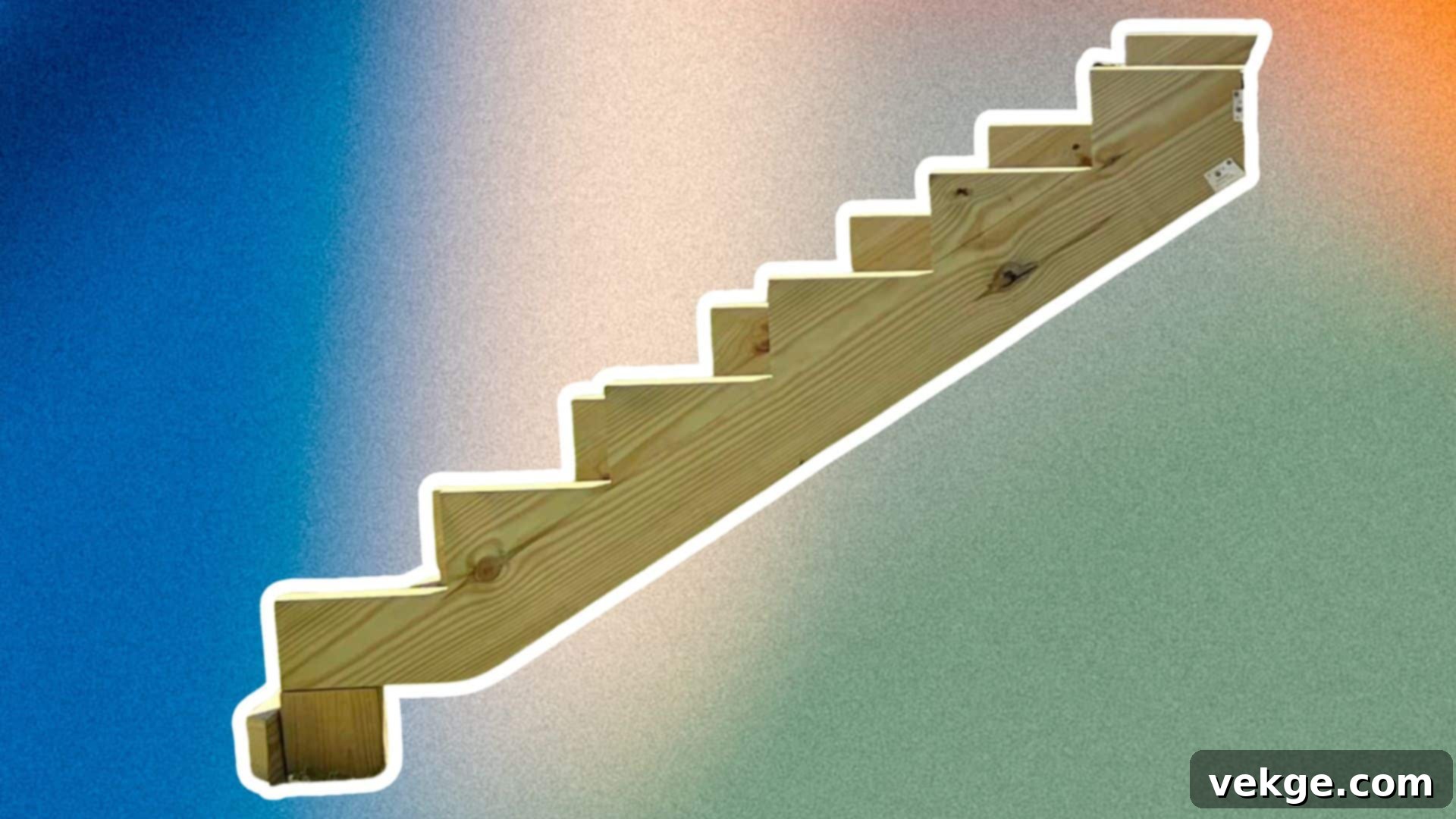

Open stringers, also known as ‘cut’ or ‘sawtooth’ stringers, showcase the profile of each step. Instead of concealing the treads and risers, notches are cut into the top edge of the stringer, creating a zigzag or sawtooth pattern. The treads then rest directly on these horizontal cuts, and the risers (if used) are typically attached between the vertical cuts, leaving the sides of the treads exposed.

These stringers are a popular choice for outdoor deck stairs and more contemporary interior designs where a lightweight or minimalist look is desired. They are generally simpler to construct than closed stringers, as they involve straightforward cutting along a layout line. This often translates to quicker installation and lower material waste.

- Pros: Easier and faster to fabricate and install; typically more cost-effective; provide a modern, open aesthetic; often preferred for outdoor deck stair applications.

- Cons: Exposed tread ends are more susceptible to wear, impact, and weather damage; less formal appearance compared to closed stringers.

Mono Stringers: The Striking, Central Support

Mono stringers represent a more modern and architectural approach to stair design. Unlike traditional staircases that use two stringers on either side, a mono stringer system utilizes a single, robust stringer positioned centrally underneath the treads. The treads are then cantilevered off this central support, often without traditional risers, creating a distinctive floating effect.

These stringers are highly favored in contemporary homes, commercial spaces, and high-end deck designs where a dramatic visual statement is desired. They create an open, airy feel and can save significant space. However, their unique design demands exceptional structural integrity from the single stringer, requiring specific engineering and often heavier gauge materials to support the cantilevered treads.

- Pros: Striking, modern, and minimalist aesthetic; creates an illusion of floating steps; saves visual space.

- Cons: Significantly more complex to engineer and install; typically the most expensive option due to specialized materials and labor; requires expert knowledge to ensure structural stability and code compliance.

Mastering Stair Stringer Calculations for Precision and Safety

Accurate calculations are the bedrock of a safe and comfortable staircase. Even a slight error in measuring or cutting stringers can lead to uneven steps, which are not only uncomfortable to walk on but also a significant tripping hazard. Before you make any cuts, ensure you have the right tools and a clear understanding of the process.

1. Essential Tools and Materials for Stringer Layout

Having the correct tools on hand will simplify the calculation and marking process, contributing to greater accuracy and safety. Here’s what you’ll need:

| Tool/Material | Purpose |

|---|---|

| Measuring Tape | Crucial for precisely measuring the total rise (vertical height) and total run (horizontal length) of the stairs. Always double-check measurements. |

| Framing Square (with stair gauges) | An indispensable tool for marking accurate, consistent right angles for each rise and run on the stringer material. Stair gauges clip onto the square for repeated marking. |

| Pencil/Marker | For clearly marking all measurements, cut lines, and layout details on the stringer lumber. A sharp pencil ensures precision. |

| Calculator | To perform all necessary arithmetic, including dividing the total rise to determine individual step rise, and calculating the total run and number of steps. |

| Circular Saw or Handsaw | For making precise cuts along the marked lines on the stringer material. A circular saw with a sharp blade is efficient for cutting lumber. |

| Safety Gear (Gloves, Safety Glasses, Ear Protection) | Essential for protecting yourself from splinters, flying debris, and noise during the measuring, marking, and cutting stages. |

| Straight Edge (e.g., a long level or another board) | Useful for checking the straightness of your stringer material and for extending lines accurately. |

2. Step-by-Step Instructions for Calculating Your Stair Stringers

Follow these steps meticulously to ensure your stair stringers are cut perfectly, leading to a safe and comfortable staircase. Remember, precision is key!

- Determine the Total Rise: This is the absolute first step. Measure the vertical distance from the finished surface of the lower landing (e.g., the ground or patio) to the finished surface of the upper landing (e.g., the deck surface). Use a long level and a measuring tape for accuracy. Let’s call this ‘Total Rise’.

- Calculate the Number of Risers and Individual Riser Height:

- Building codes typically mandate a maximum riser height (often around 7 to 7.75 inches, check local codes). A comfortable individual riser height for most people is between 6.5 and 7.5 inches.

- Divide your ‘Total Rise’ by an approximate ideal riser height (e.g., 7 inches). This will give you a rough number of steps.

- Round this number to the nearest whole number. This is your ‘Number of Risers’.

- Now, divide your ‘Total Rise’ by this ‘Number of Risers’ to get your precise ‘Individual Riser Height’. This ensures all risers are exactly the same height. For instance, if your Total Rise is 56 inches, and you divide by 7, you get 8 risers. Then 56 / 8 = 7 inches per riser.

- Determine the Individual Tread Run (Depth) and Total Run:

- Building codes also specify a minimum tread run (often 10 to 11 inches, excluding nosing). A comfortable individual tread run is typically 10 to 12 inches.

- The ‘Number of Treads’ will always be one less than the ‘Number of Risers’ (because the top deck surface acts as the final tread).

- Once you’ve chosen your desired individual tread run (e.g., 10 inches), multiply this by your ‘Number of Treads’ to get the ‘Total Run’. This is the total horizontal distance your stairs will occupy.

- Layout the Stringers:

- Take your chosen stringer material (typically 2×10 or 2×12 pressure-treated lumber for decks) and your framing square equipped with stair gauges set to your ‘Individual Riser Height’ and ‘Individual Tread Run’.

- Starting from one end, carefully mark the first rise and run. Then, slide the square along the board, marking each subsequent rise and run. Be meticulous; any error here will compound.

- Mark the top and bottom cuts. The top cut will typically be a plumb cut (vertical) to meet the deck rim joist, and the bottom cut will be a level cut (horizontal) to rest on the landing, often with a ‘bottom step reduction’ to account for the thickness of the first tread.

- Double-Check and Cut: Before cutting, re-measure everything. Use a long straight edge to ensure all your marked points align. Once confident, use a circular saw or handsaw to carefully cut along your marked lines. Always cut on the waste side of the line.

- Consult Local Building Codes: This cannot be stressed enough. Codes vary by location and dictate specific maximum riser heights, minimum tread depths, handrail requirements, and stringer spacing. Always check with your local building department or a professional to ensure your calculations and design comply. If you’re unsure, seeking professional assistance can prevent costly mistakes and ensure safety.

Installing Stair Stringers: A Guide to Secure and Stable Deck Stairs

Once your stringers are precisely calculated and cut, the installation process is where they come to life as the structural framework of your stairs. Proper installation is crucial for the safety, stability, and longevity of your deck staircase. Here’s a detailed guide to installing them correctly:

- Prepare the Site and Mark Placement:

- Ensure the ground where the stairs will land is firm, level, and well-drained. You may need to pour a concrete pad or install sturdy footings to create a stable base for the stringers.

- Mark the exact location where your stringers will attach to the deck’s rim joist or header at the top, and where they will rest at the bottom. Accuracy at this stage prevents misalignment later.

- Secure the Top of the Stringers:

- Attach the top of each stringer to the deck’s rim joist or a specially installed header. This connection is critical. Use heavy-duty, corrosion-resistant framing connectors or strong metal hangers specifically designed for this purpose. These fasteners are designed to handle significant shear and withdrawal loads.

- Ensure the stringers are plumb (perfectly vertical) at the top connection point and that the top tread line is level with the deck surface.

- Align and Space the Stringers:

- For most deck stairs, you’ll need at least two stringers. For wider stairs, or if you’re using thinner treads, you may need three or more stringers to prevent sagging.

- General guidelines suggest spacing stringers no more than 16-18 inches on center, but local codes or tread material specifications may require closer spacing (e.g., 12 inches on center for composite decking).

- Use a level and a measuring tape to ensure all stringers are parallel, evenly spaced, and perfectly aligned from top to bottom. Temporary bracing might be necessary to hold them in place during initial fastening.

- Anchor the Bottom of the Stringers:

- Securely anchor the bottom of each stringer to your prepared base (concrete pad, footings, or ground-level joists). Use appropriate anchors for the material, such as concrete expansion bolts for a concrete pad or Simpson Strong-Tie angle brackets for wood connections.

- It’s often recommended to slightly elevate the bottom of the stringers off the ground, perhaps with a small piece of treated lumber or a stand-off bracket, to prevent direct contact with moisture, which can lead to rot, especially with pressure-treated wood. This also helps with drainage.

- Attach Treads and Risers (if applicable):

- Once the stringers are firmly in place, you can begin attaching the stair treads and risers.

- Pre-drill pilot holes for all fasteners to prevent splitting the wood, especially at the ends of the treads and risers.

- Use galvanized or stainless steel screws (at least 2.5 to 3 inches long) for a strong, corrosion-resistant connection. Do not use nails for structural stair components, as they have less pull-out resistance.

- Ensure each tread is level and securely fastened to each stringer. If you’re installing risers, ensure they are plumb and tightly fitted.

- Final Checks and Testing:

- After installation, perform a thorough final check. Verify that all connections are tight, the stairs are stable, and all treads are level and consistent.

- Walk up and down the stairs several times to test their stability and comfort. Listen for any creaks or wobbles that might indicate a loose connection or an issue with the stringer support.

Remember that regular maintenance, especially for outdoor deck stairs, is vital. Inspect your stringers annually for any signs of rot, insect damage, cracking, or loose fasteners. Promptly addressing these issues will help maintain the safety and structural integrity of your staircase for many years to come.

Wrapping It Up: Your Foundation for Flawless Deck Stairs

We’ve journeyed through the intricate world of stair stringers, from their fundamental definition to the nuances of their calculation, installation, and critical role in deck construction. By now, you should be well-equipped with a comprehensive understanding that empowers you to approach your next staircase project with confidence and expertise.

It’s clear that stair stringers are the unsung heroes of any staircase, acting as the primary structural support that ensures both safety and stability. Whether your design preference leans towards the traditional elegance of closed stringers, the modern simplicity of open stringers, or the striking minimalism of a mono stringer, each type plays a vital role in creating the desired aesthetic and structural integrity.

The importance of meticulous calculation cannot be overstated; accurate measurements of rise and run are the bedrock of a comfortable, code-compliant, and safe staircase. Similarly, precise installation, from securing the top connection to anchoring the base, is paramount to prevent hazards and ensure longevity. Always remember to consult local building codes as they are your definitive guide to safe construction practices and will protect you from potential liabilities.

For those moments of uncertainty or for complex designs, never hesitate to seek professional help. A qualified contractor or structural engineer can provide invaluable guidance, ensuring your deck stairs are built to the highest standards. Furthermore, consistent maintenance and regular inspections will prolong the life of your stairs, keeping them safe and beautiful for countless seasons.

So, the next time you ascend or descend a set of stairs, take a moment to appreciate the robust, unseen work of the stringers beneath your feet. They are the silent, steadfast supporters, making every confident step possible and forming the true foundation of your deck’s accessibility and charm.