Mastering Air-Dry Clay: The Ultimate Guide to Perfect Drying, Painting, and Sealing

Working with air-dry clay offers a wonderfully relaxing and creative outlet, transforming simple ideas into tangible art. However, my journey began with a common frustration: the long, often unpredictable waiting game for my creations to dry. I’d painstakingly shape a piece I was truly proud of, only to rush the painting process, resulting in disappointing cracks, unsightly smudges, or peeling paint.

This comprehensive guide is born from those hard-learned lessons. My goal is to equip you with the knowledge and techniques necessary to avoid the pitfalls I encountered. You’ll discover precisely how long air-dry clay typically takes to dry, how to confidently determine if your piece is ready for the next step, and safe, effective methods to gently accelerate the drying process without compromising your artwork.

Beyond drying, this guide provides actionable advice for achieving professional-looking finishes. We’ll cover simple yet crucial tips for sanding, priming, painting, and sealing your air-dry clay projects, ensuring they not only look fantastic but also stand the test of time. Prepare to elevate your air-dry clay crafting experience, turning every project into a lasting success story.

Understanding Air-Dry Clay Drying Times

The time it takes for air-dry clay to fully cure isn’t a fixed measure; it varies significantly based on the specific type of material you’re using. Each formulation has unique properties that dictate its drying speed and how it behaves during the evaporation process. Understanding these differences is the first step toward successful crafting.

Drying Times by Types of Air-Dry Clay

- Foam-Based Clay: This distinct type of air-dry clay is known for its incredibly soft, spongy texture and lightweight nature. Its composition, often including tiny foam beads, allows for quicker moisture evaporation. Consequently, foam-based clay typically dries faster than other varieties, often becoming completely dry within 24 to 48 hours. Once dry, it retains its lightweight quality and offers a degree of flexibility, making it an excellent choice for intricate, delicate pieces, small decorative items, or crafts where weight is a concern. Its soft consistency also makes it forgiving for beginners.

- Paper-Based Clay: Crafted with natural paper pulp blended with binders, this clay boasts a unique fibrous texture. While it offers excellent structural integrity and holds fine details beautifully, the presence of paper fibers means it tends to absorb and retain more moisture initially. As a result, paper-based clay typically has a longer drying period. Thicker pieces may require anywhere from three to five days to fully dry. Its slow drying time contributes to less cracking, and once dry, it’s exceptionally easy to sand, carve, or shape, making it ideal for sculptures, masks, and projects requiring a smooth finish.

- Resin or Polymer-Based Clay: These formulations are designed for superior strength and durability. They are denser and heavier than their foam or paper counterparts, often incorporating synthetic polymers or resins. This robust composition means they take longer to release their moisture, frequently requiring 72 hours or more for complete drying. When cured, resin or polymer-based clays produce very sturdy, solid pieces capable of holding intricate details with high precision. They are best suited for functional items, decorative pieces that need to withstand handling, or designs that demand extra resilience and a professional finish.

It’s crucial to remember that these are general estimates. Factors such as the thickness of your creation, the specific environmental conditions, and the amount of airflow will further influence the actual drying time, even among different batches of the same clay type. Always consider these variables when planning your project.

Key Factors Influencing Air-Dry Clay Drying Time

Achieving perfectly dried air-dry clay isn’t just about patience; it’s about understanding the environmental dynamics that govern the drying process. Several interconnected factors can significantly alter how quickly, or slowly, your clay piece cures. By mastering these elements, you can better control your project’s timeline and prevent common problems like cracking or warping.

1. Thickness and Shape

The most straightforward factor is the physical dimension of your creation. Simply put, the thicker your clay piece, the longer it will take for moisture to evaporate from its core. A thin, flat ornament, for instance, might be fully dry in a single day, while a robust, round sculpture with deep contours or varied thicknesses could easily demand three days or more. Uneven thickness is a particularly tricky aspect; parts that dry faster can shrink more quickly, creating internal stresses that often lead to unsightly cracks in slower-drying, thicker sections. Aim for uniform thickness whenever possible, or gradually thin out areas that need to dry faster.

2. Humidity and Temperature

The atmosphere surrounding your clay plays a pivotal role. High humidity in the air acts as a natural barrier, reducing the rate at which moisture can evaporate from your clay. If your room feels damp, or you live in a humid climate, expect a noticeably extended drying period. Conversely, a warm, dry environment significantly accelerates evaporation. Optimal drying conditions typically involve a comfortable room temperature (around 68-75°F or 20-24°C) and moderate to low humidity. Avoid placing your clay in damp basements, chilly corners, or directly near humidifiers, as these conditions will prolong drying and could even encourage mold growth.

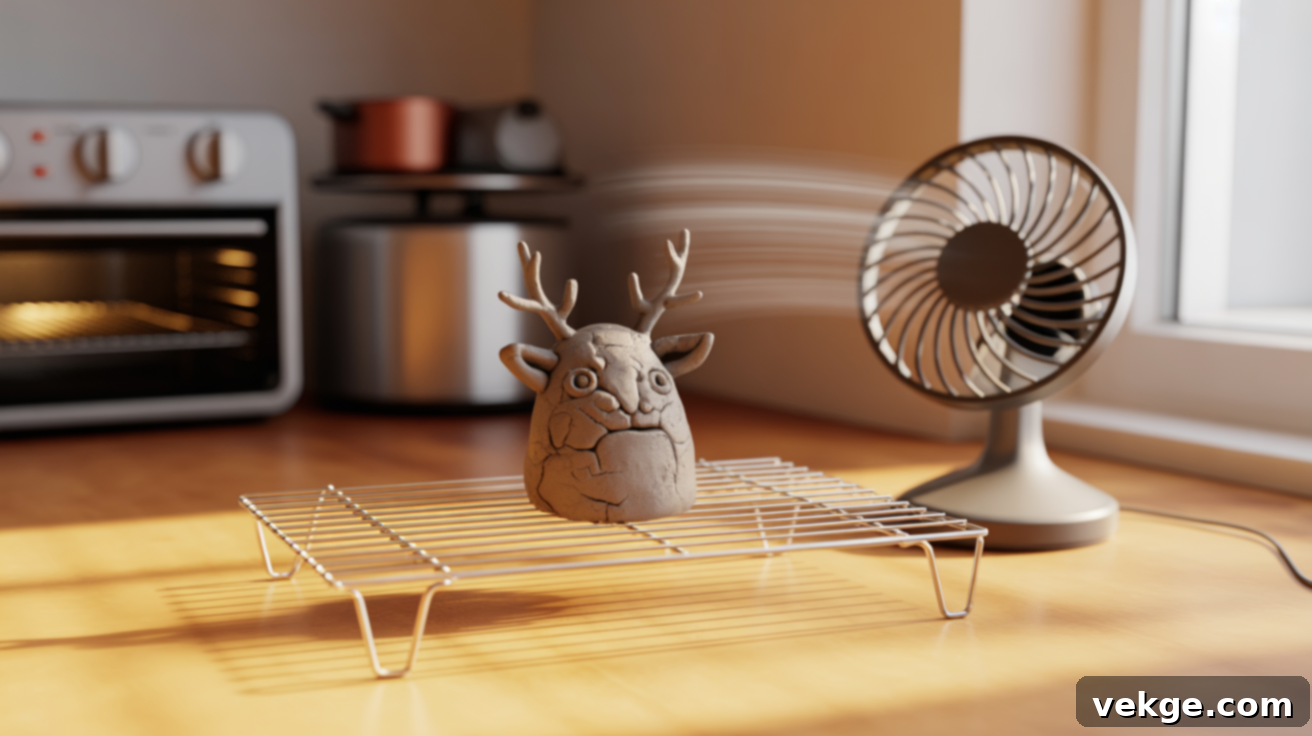

3. Ventilation and Airflow

Effective air circulation is paramount for efficient drying. Moving air helps to carry away the evaporated moisture from the clay’s surface, creating a continuous drying cycle. Place your clay pieces in an open space where air can freely circulate from all sides. Using a wire rack, a cooling tray, or even small blocks to elevate your piece ensures that air reaches the bottom, preventing moisture from pooling. Avoid resting your clay directly on a flat, non-porous surface, which can trap moisture and cause the bottom to dry much slower than the top. While good airflow is beneficial, direct, strong drafts (like from an open window on a windy day or a high-speed fan directly on the clay) can sometimes lead to rapid surface drying while the interior remains wet, increasing the risk of cracking. Aim for gentle, consistent air movement.

Experimenting with small test pieces under your specific home conditions can provide invaluable insights into how your chosen clay behaves, helping you fine-tune your drying strategy for future projects.

How to Confirm Your Air-Dry Clay is Fully Dry

Patience is a virtue in air-dry clay crafting, especially when waiting for your piece to dry. Rushing this critical step can lead to a host of problems down the line, from peeling paint to structural weaknesses. Knowing how to definitively tell if your clay is completely dry is essential before proceeding to sanding, painting, or sealing. Here are the key indicators to look for:

- Tactile Assessment (Touch): A fully dry piece of air-dry clay should feel firm, solid, and completely rigid to the touch. There should be no give, softness, or stickiness, even in thicker sections. If any part feels cool or slightly damp, it means moisture is still present and more drying time is needed. The surface should also feel smooth and hard, almost like a ceramic bisque.

- Auditory Test (Sound): Gently tap your clay piece with your fingernail or a small, hard tool. A crisp, solid, and clear sound indicates thorough dryness. If you hear a dull thud or a hollow sound, it often suggests that moisture is still trapped inside, especially in the core of thicker areas. This is one of the most reliable tests for internal dryness.

- Visual Cues (Color Change): Most types of air-dry clay undergo a noticeable color change as they dry. Often, they lighten in shade, becoming paler or more opaque. Observe your piece closely; the color should be uniform across the entire surface, including crevices and undersides. Any darker patches indicate areas that are still wet. While small, hairline cracks can sometimes appear in thicker sections as moisture leaves the clay, a consistent overall color is a strong sign of dryness.

- Weight Test (Optional but helpful): As clay loses moisture, it also loses weight. If you’re working on a larger piece, you might notice a subtle but discernible difference in weight between a wet and a fully dry piece. This is less practical for small items but can be an additional confirmation for substantial sculptures.

It’s important to check all these signs, not just one. The surface can often feel dry long before the interior has fully cured. Waiting an extra day or two after you *think* it’s dry is always a safer bet than moving forward too soon, especially for thicker items.

Safe Methods to Speed Up Air-Dry Clay Drying

While patience is generally recommended for air-dry clay, there are instances when you might need your project to dry a bit faster. Fortunately, you can safely accelerate the process without causing damage like cracks or warping, provided you use gentle methods and constant vigilance.

Optimizing Air Circulation

Enhanced airflow is the safest and most effective way to speed up drying. Place your clay piece on a wire rack, a cooling tray, or even small wooden blocks. This elevation allows air to circulate freely around the entire surface, including the bottom, which is often overlooked. You can further improve airflow by placing your piece in an open, well-ventilated room, perhaps near an open window. If using a fan, position it so that it creates a gentle, indirect breeze across the room rather than blowing directly onto the clay. A direct, strong blast of air can dry the surface too quickly, potentially leading to cracks while the interior remains wet.

Controlled Heat Applications

For smaller, thinner pieces, controlled, low-temperature heat can be used cautiously. This method is not recommended for large or very thick sculptures, as uneven heating can cause severe cracking:

- Oven Drying: If using an oven, set it to the lowest possible temperature, typically around 200°F (90-100°C). Place your clay on a baking sheet lined with parchment paper. Leave the oven door slightly ajar to allow moisture to escape. Bake for short intervals, typically 15 to 20 minutes at a time, checking the clay frequently. Remove it, let it cool completely, and then re-evaluate its dryness. Repeat this process until fully dry. Never leave clay unattended in the oven, and avoid high temperatures, which can bake the clay too quickly, leading to extensive cracking or even burning.

- Food Dehydrator: A food dehydrator, set to its lowest heat setting, can also be a safe option for small to medium-sized pieces. The consistent low heat and controlled airflow are ideal. Place the clay on the dehydrator trays and check every hour or so until dry. This method is gentler than an oven and reduces the risk of overheating.

- Hair Dryer (with caution): For very small, thin areas that need a little extra help, a hair dryer on its lowest, coolest setting can be used. Hold it several inches away and move it continuously to avoid concentrating heat on one spot, which can cause cracking. This is more of a spot-drying technique rather than a primary drying method.

What to Avoid When Speeding Up Drying

To prevent irreversible damage to your creations, steer clear of these common mistakes:

- Direct Sunlight: While seemingly helpful, direct sunlight can cause the clay surface to dry and shrink too rapidly, almost guaranteed to result in cracks, especially on uneven or thicker pieces.

- Microwave Ovens: Microwaving clay can cause the internal moisture to heat up and expand too quickly, leading to explosive cracking or structural collapse. It’s highly unpredictable and generally destructive.

- High Heat Settings: Never use a hot oven or strong heat sources. Rapid, intense heat causes the outer layer to dry instantly, trapping moisture inside and leading to severe cracking and internal weaknesses.

- Sealing in Containers: Ironically, sealing wet clay in an airtight container will prevent it from drying altogether and will likely lead to mold growth.

Always prioritize slow, even drying when possible. If you must speed things up, do so gently and with careful monitoring to protect your creative efforts.

The Critical Importance of Waiting: Why You Shouldn’t Paint Wet Air-Dry Clay

The temptation to paint your air-dry clay creation as soon as it feels somewhat firm is strong, especially when you’re excited to see your vision come to life. However, succumbing to this urge is one of the most common and detrimental mistakes crafters make. Painting air-dry clay before it is completely, unequivocally dry will almost certainly lead to disappointing, long-term problems that can ruin your artwork.

Risks of Painting Wet Clay

Even if the surface of your clay feels dry to the touch, the interior might still harbor significant moisture. Air-dry clay dries from the outside in, and internal dampness creates a host of issues when paint is applied:

- Poor Paint Adhesion and Peeling: Wet clay continues to release moisture as it dries. This moisture attempts to escape through the painted surface, preventing the paint from properly adhering to the clay. Over time, this often results in the paint flaking, bubbling, or peeling away, completely undermining your hard work.

- Cracking and Warping: As the clay underneath continues to dry and shrink (a natural process for air-dry clay), the rigid paint layer applied too early cannot flex with these changes. This differential movement causes immense stress, leading to unsightly cracks not only in the paint but potentially in the clay itself, or even causing the entire piece to warp.

- Blotchy and Dull Colors: Wet clay can absorb paint unevenly, especially water-based paints. This results in blotchy, inconsistent color application. The moisture within the clay can also dilute the paint pigment, causing colors to appear duller and less vibrant than intended, or even change hue altogether.

- Mold Growth: Trapping moisture beneath a layer of paint creates an ideal environment for mold and mildew to grow. This can cause discoloration, an unpleasant odor, and can eventually degrade the clay itself, leading to a ruined piece.

- Smudging and Mixing: If the clay is still even slightly damp, the paint may smear easily or mix with the clay’s natural moisture, leading to a messy, unprofessional finish that is difficult to correct.

The consequences of painting prematurely are not just superficial; they can compromise the structural integrity and aesthetic longevity of your entire project. Waiting until the clay is bone dry ensures that the paint has a stable, consistent, and inert surface to adhere to, allowing for a much smoother, more vibrant, and truly long-lasting finish.

Preparing Dry Air-Dry Clay for a Flawless Paint Job

Once your air-dry clay is absolutely, unequivocally dry, the next crucial step is preparation. Proper preparation is the secret to ensuring your paint adheres beautifully, looks vibrant, and lasts for years. Skipping these steps can lead to disappointing results, regardless of the quality of your paint.

1. Sand the Surface for Smoothness

Air-dry clay, even when carefully molded, often dries with minor imperfections: tiny bumps, visible seams, or slight rough patches. These irregularities can show through your paint, making your finished piece look less refined. To achieve a professional, smooth finish, gentle sanding is essential. Start with a medium-grit sandpaper (around 180-220 grit) to tackle larger bumps, then move to a finer grit (300-400 grit) for a silken touch. Sand gently and evenly across the entire surface. For safety, always wear a dust mask to avoid inhaling fine clay particles, and work in a well-ventilated area.

2. Thoroughly Clean Off Dust

After sanding, your clay piece will be covered in a fine layer of dust. This dust is the enemy of good paint adhesion. If left on the surface, it will create a gritty texture and prevent the paint from bonding properly, leading to flaking or a dull finish. Use a soft, dry brush (like a dedicated craft brush or an old makeup brush) to meticulously brush away all visible dust. For an even cleaner surface, you can lightly wipe the clay with a barely damp cloth. If you use a damp cloth, ensure the clay is completely dry again before proceeding to the next step, as any residual moisture can cause problems.

3. Apply Primer: The Foundation of Good Paint

Priming your air-dry clay is a step that many beginners overlook, but it’s vital for achieving the best painting results. A thin, even coat of primer acts as a barrier and an adhesive layer. It does several important things:

- Enhances Paint Adhesion: Primer creates a smooth, uniform surface that paint can grip onto much better than raw clay.

- Ensures Even Color: Clay can be porous and absorb paint unevenly, leading to blotchy colors. Primer seals the surface, ensuring your topcoats of paint lay down smoothly and consistently.

- Boosts Color Vibrancy: Especially for lighter paints, a white or light-colored primer provides a neutral base, making your chosen paint colors appear truer and more vibrant.

- Reduces Paint Consumption: By sealing the clay’s porosity, primer prevents the clay from “drinking” too much paint, saving you material and ensuring better coverage with fewer coats.

Brush on a thin, even coat of a good quality acrylic gesso or a multi-surface craft primer. Allow the primer to dry completely according to the manufacturer’s instructions before applying any paint. For very porous or dark clay, a second thin coat of primer might be beneficial.

Choosing the Best Paints for Your Air-Dry Clay Creations

With your air-dry clay perfectly dry and prepped, it’s time to infuse it with color. The choice of paint is crucial, as each type offers different characteristics in terms of finish, durability, and ease of use. Selecting the right paint will enhance your project’s aesthetic and longevity.

Best Paint Types for Air-Dry Clay

| Paint Type | Drying Time | Surface Needs | Best For | Notes |

|---|---|---|---|---|

| Acrylic Paints | Fast (minutes to an hour) | Primed, dry clay for best results | General crafts, detailed work, vibrant colors, durable finishes | Water-based, easy cleanup, wide range of colors/finishes (matte, satin, gloss). Excellent for layering. |

| Tempera Paints | Medium (30-60 minutes) | Dry, unsealed, or primed clay | Kids’ projects, temporary decorations, educational crafts | Non-toxic, opaque, good coverage but less durable. Can wash off or rub away if not sealed well. |

| Watercolor Paints | Slow (due to water content) | Sealed or heavily primed clay is essential | Light, translucent washes, soft artistic finishes, subtle effects | Can bleed and absorb into unprimed clay. Requires excellent sealing to prevent smudging and fading. Best for artistic, less durable pieces. |

| Gouache Paints | Medium (similar to tempera) | Primed, dry clay | Opaque, matte finishes, vibrant colors, fine art illustration | Essentially opaque watercolor. Dries matte and can be re-wetted. Needs sealing for durability and water resistance. |

| Spray Paints | Fast (minutes) | Primed, dry clay, well-ventilated area | Even base coats, quick coverage, metallic or specialty finishes | Great for large areas. Apply in light, even coats to avoid drips. Requires good ventilation and mask. Some types can be strong. |

Painting Techniques and Tips

- Apply Thin Coats: Regardless of paint type, always apply paint in thin, even layers. Thick coats can become gummy, take longer to dry, and are more prone to cracking or peeling.

- Dry Between Layers: Allow each coat of paint to dry completely before applying the next. This prevents smearing, allows colors to build up vibrantly, and ensures a durable finish.

- Use Quality Brushes: Good quality brushes suitable for your chosen paint type will make a significant difference in application smoothness and detail.

- Practice Blending: If you’re aiming for blended colors or intricate details, practice on a scrap piece of clay first.

By thoughtfully choosing your paint and applying it with care, you’ll ensure your air-dry clay creations boast beautiful, lasting color.

Sealing Your Painted Air-Dry Clay for Longevity and Protection

Once your paint has fully dried and you’re delighted with your creation’s appearance, the final and arguably most crucial step is sealing. Sealing not only protects your artwork from environmental damage and wear but can also enhance its finished look. It’s the protective shield that ensures your hard work endures.

Why Sealing is Essential

- Moisture Protection: Air-dry clay, even when dry, can be somewhat porous. A sealant creates a barrier that helps prevent moisture absorption, which can soften the clay or cause paint to degrade over time.

- Durability and Wear: Sealants add a layer of protection against scratches, scuffs, and general handling, making your piece more robust and suitable for various uses.

- UV Protection: Many sealers offer UV resistance, which helps prevent paint colors from fading over time when exposed to sunlight.

- Enhances Finish: Sealers come in various finishes (matte, satin, glossy), allowing you to customize the final look of your piece, adding depth and vibrancy to the colors.

- Prevents Dirt Accumulation: A sealed surface is smoother and less porous, making it easier to dust and clean without damaging the paint.

Choosing the Right Sealer

The type of sealer you choose depends on your desired finish, the level of protection needed, and whether the piece will be for indoor or outdoor display:

- Acrylic Varnishes (Brush-on or Spray): These are widely popular due to their versatility and excellent protective qualities. They come in various finishes (matte, satin, gloss) and are generally water-resistant once dry. Brush-on varnishes offer more control for small details, while spray varnishes are ideal for larger, uneven, or textured surfaces, providing a smooth, even coat without brushstrokes.

- Mod Podge: A multi-purpose craft adhesive, sealer, and finish. It’s available in matte, gloss, and satin. While effective for light protection, it’s not as durable or water-resistant as dedicated varnishes, making it better for decorative indoor pieces than high-wear items.

- Resin Sealers: For the highest level of durability and a super-glossy, glass-like finish, clear epoxy resin can be used. This creates a very hard, protective layer but requires careful mixing and application, and adds significant weight.

- Outdoor Specific Sealers: If your air-dry clay creation is destined for the garden or any outdoor setting, you must use a heavy-duty, outdoor-grade waterproof sealant. These are formulated to withstand extreme weather, UV rays, and moisture penetration.

Sealer Application Best Practices

- Ensure Paint is Completely Dry: This cannot be stressed enough. Applying sealer over even slightly damp paint can trap moisture, causing cloudiness, bubbling, or peeling of both the paint and the sealer.

- Choose the Right Method: For larger or intricate pieces, spray sealers often provide a more even coat. For smaller, flatter areas, a brush-on varnish offers more control.

- Apply Thin, Even Coats: Whether spraying or brushing, several thin coats are always superior to one thick coat. Thick coats can create drips, unevenness, take longer to dry, and potentially become cloudy or tacky. Aim for at least two light coats.

- Allow Drying Between Coats: Give each layer of sealer ample time to dry completely according to the product’s instructions before applying the next. This ensures proper adhesion and a smooth finish.

- Work in a Well-Ventilated Area: Especially for spray sealers or solvent-based varnishes, adequate ventilation is crucial to disperse fumes and prevent inhalation.

- Test on a Scrap Piece: If you’re unsure how a particular sealer will react with your specific paint or clay, always test it on a small, inconspicuous area or a scrap piece first. This helps you confirm the finish and compatibility.

A properly applied sealer will not only protect your air-dry clay piece but will also bring out the best in your colors and craftsmanship, ensuring your artwork looks vibrant and lasts for years to come.

Troubleshooting Common Air-Dry Clay Mistakes and How to Fix Them

Even with the best intentions and careful execution, minor mishaps can occur when working with air-dry clay. The good news is that most common problems are preventable and, if they do arise, often come with straightforward solutions. Understanding these issues will help you troubleshoot and learn from each project, leading to increasingly successful outcomes.

Cracks During Drying

- Cause: Cracks are usually caused by uneven drying, drying too quickly, or making the clay too thick. When the surface dries and shrinks faster than the interior, stress builds up, leading to fractures.

- Prevention:

- Ensure uniform thickness in your clay pieces.

- Promote slow, even drying by avoiding direct heat, strong drafts, or sunlight.

- Cover your piece loosely with plastic wrap or a damp cloth during the initial drying phase to slow down surface drying, allowing the interior to catch up.

- For very thick pieces, consider hollowing out the interior when the clay is still damp.

- Fix: For hairline cracks, mix a small amount of fresh air-dry clay with a tiny bit of water to create a paste (a “slip”). Apply this paste into the cracks with a small tool or your finger, smoothing it over. Allow it to dry completely, then sand if necessary. For larger cracks, you might need to fill the gap with fresh clay, blend it, and let it dry thoroughly.

Paint Peeling or Bubbling

- Cause: This almost always indicates that the clay was not fully dry before painting, or that the surface was not properly cleaned and primed. Moisture trapped beneath the paint, or a dusty/oily surface, prevents proper adhesion.

- Prevention:

- ALWAYS ensure your clay is bone dry before painting (refer to “How to Tell If It’s Fully Dry” section).

- Clean off all sanding dust.

- Apply a good quality primer.

- Fix: If the peeling is minor, you might be able to gently scrape off the loose paint, re-sand the area, clean it, re-prime, and then repaint. For extensive peeling, it’s often best to remove all paint (if possible), ensure the clay is dry, and restart the preparation and painting process.

Uneven Surfaces or Lumps

- Cause: These result from inadequate shaping during the wet stage or insufficient sanding after drying.

- Prevention:

- Smooth your clay thoroughly with tools or damp fingers while it’s still wet.

- Allow for proper drying time before sanding.

- Fix: Once dry, use a range of sandpaper grits (starting with coarser, then moving to finer) to carefully sand down any rough or lumpy spots until the surface is smooth. For very deep imperfections, a small amount of clay slip or a fine-grain spackling paste (designed for crafts) can be used to fill and then sanded smooth once dry.

Dull or Blotchy Paint

- Cause: This often happens when paint is applied to unprimed clay, applied too thickly, or when the clay was not completely dry. Porous clay absorbs paint unevenly, leading to a dull or inconsistent finish.

- Prevention:

- Always use a primer.

- Apply paint in thin, even coats, allowing each layer to dry completely.

- Ensure the clay is fully dry before any painting begins.

- Fix: If the paint is dull or blotchy, you might need to apply additional thin coats of paint over the existing ones to build up opacity and evenness. If the issue is severe, allow everything to dry, lightly sand, re-prime, and then repaint with thin layers. A good quality sealer can sometimes deepen and unify colors, improving the overall appearance.

Mold Growth

- Cause: Mold typically occurs when air-dry clay is kept in a damp, poorly ventilated environment for too long, or if it doesn’t dry properly. Trapped moisture is the primary culprit.

- Prevention:

- Ensure good airflow and low humidity during drying.

- Avoid storing wet clay in airtight containers for extended periods.

- Ensure clay is thoroughly dry before sealing or storing.

- Fix: For minor surface mold on an undried piece, you can sometimes gently scrape it off, then allow the piece to dry thoroughly in a well-ventilated area. For widespread mold, especially if it has penetrated deeply, the piece may need to be discarded to prevent further spread.

Embracing these small fixes and learning from each project will significantly improve your skills and the quality of your air-dry clay creations, leading to smoother finishes and longer-lasting results.

Conclusion

You’ve now navigated the comprehensive guide to mastering air-dry clay, understanding the intricate dance of drying, painting, and sealing. We’ve explored how crucial timing, meticulous surface preparation, and the thoughtful selection of materials all converge to define the success and longevity of your projects. From deciphering the unique drying characteristics of various clay types to employing safe methods for accelerating the process, you’re now equipped with a robust toolkit.

Gone are the days of uncertainty about when to pick up that paintbrush or the frustration of discovering hairline cracks after hours of effort. By adhering to the principles outlined here – especially the paramount importance of complete dryness before any further steps – you can sidestep most common setbacks. This isn’t about guesswork; it’s about applying proven techniques that guarantee smoother finishes, vibrant colors, and durable creations.

Take what you’ve learned within these pages and confidently apply it to your next air-dry clay endeavor. Let your creativity flourish, unburdened by past frustrations. And remember, the world of crafting is vast and full of continuous learning. For more inspiration, detailed tutorials, or advanced techniques, we invite you to explore our other blogs dedicated to clay and craft projects. Happy crafting!