The Ultimate DIY Guide to Building Custom Banquette Seating for Your Home

Are you dreaming of adding extra seating to your kitchen or dining area but struggling to find furniture that perfectly fits your space and style? Many homeowners face this common dilemma, especially in compact living spaces. Last year, I found myself in the exact same situation with my small kitchen. The perfect solution? Building a custom banquette. This project not only maximized my available space but also added a unique, built-in charm and unparalleled functionality that store-bought pieces simply couldn’t achieve.

The idea of constructing your own custom banquette seating might initially seem daunting, conjuring images of complex carpentry. However, I’m here to assure you that it’s a highly achievable DIY project for anyone with basic woodworking tools, a willingness to learn, and a desire to enhance their home. With this comprehensive guide, you can create a beautiful, custom-made dining bench that is perfectly tailored to your home’s specific dimensions and aesthetic preferences, offering both comfort and smart storage solutions.

This in-depth guide will take you through every essential step of building a DIY banquette from start to finish. We’ll cover critical planning considerations, help you select the right materials for durability and comfort, guide you through the process of building a sturdy base frame, show you how to add comfortable cushions, and finally, add those all-important finishing touches that make your banquette truly shine. Let’s embark on this exciting journey to transform your dining space into a more inviting and efficient area with custom banquette seating!

Planning Your Custom Banquette Seating Project: Essential Steps for Success

A successful banquette construction hinges on meticulous planning, with accurate measurements being the cornerstone. When I built my own custom dining bench, I quickly realized that precision in the planning phase simplifies every subsequent step, minimizing errors and ensuring a perfect, seamless fit for your kitchen or dining nook.

- Measure Your Space Thoroughly: Start by grabbing your trusty tape measure. Carefully record the entire length of the wall where your banquette will be situated. Don’t forget to measure the height as well, from the floor to any windowsills or architectural features. For optimal comfort for most adults, I highly recommend a finished seat height of approximately 18 inches (46 cm), which includes the cushion. This standard height allows for comfortable dining with most tables.

- Determine Ideal Seat Depth: Next, consider the depth of your seating. From my experience and extensive research, a finished seat depth of around 20 inches (51 cm) provides ample room for comfortable sitting without protruding too far into your floor space. This depth strikes a perfect balance between comfort and space efficiency, crucial for small kitchens.

- Consider Table Placement for Ergonomics: The relationship between your banquette and dining table is crucial for a comfortable dining experience. Aim to leave approximately 12 inches (30 cm) of clearance between the edge of your dining table and the front edge of the banquette seat. This gap is essential for allowing people to slide in and out of the seating area with ease, preventing cramped feelings or awkward maneuvering. Ensure your table’s height also complements your banquette’s height.

- Sketch Your Vision and Finalize Design: My final, invaluable tip for the planning stage is to draw a simple, scaled sketch of your space, incorporating all these precise measurements. This visual aid will become your indispensable reference when purchasing materials and throughout the construction process. It acts as a blueprint, helping you visualize the finished product and significantly reducing the likelihood of costly mistakes due to miscalculations. Decide if you want a straight bench, L-shape, or U-shape, and if you’ll incorporate storage.

Taking the time to plan meticulously will not only save you time and money but also result in a DIY banquette that feels perfectly integrated and custom-made for your home, providing a beautiful and functional dining nook.

Building Your DIY Banquette Seating: A Step-by-Step Construction Guide

Once your meticulous planning is complete and you have a clear vision of your custom banquette seating, it’s time to gather your tools and materials and bring your banquette vision to life. This section will guide you through the practical steps of construction, ensuring a sturdy, durable, and beautiful result that will be a focal point in your kitchen or dining area.

Essential Tools & Materials Required for Your Custom Banquette Project

Before you begin cutting and assembling, ensure you have all the necessary tools and materials on hand. Having everything ready beforehand streamlines the process and prevents frustrating delays, making your DIY banquette build much smoother.

| Tools Required | Materials Required |

|---|---|

| Circular saw or table saw: Essential for precise, straight cuts on lumber and plywood. A table saw offers superior accuracy and efficiency for repetitive cuts, making it ideal for large projects. | 2×4 lumber: The backbone of your banquette, used for creating robust internal frames and structural supports. Choose straight, knot-free pieces for maximum stability. |

| Brad nailer: Speeds up the process of attaching plywood sheathing and trim with small, discreet nails, providing a strong hold with minimal visual impact. | 1/4 inch plywood: Used for the outer sheathing, providing a smooth, paintable surface for the bench sides and back. It’s flexible enough for some gentle curves if desired. |

| Self-tapping screws (wood screws): Crucial for securely joining 2×4 lumber pieces to form strong, durable frames. Use screws long enough to penetrate both pieces of wood effectively. | 1×3 boards: Perfect for decorative trim work, covering raw plywood edges, and adding a refined, finished look to your custom dining bench. |

| Measuring tape: Your most important tool for accurate measurements throughout the entire project, ensuring everything fits perfectly. | 3/4 inch plywood: Ideal for the sturdy bench top, especially if you plan for a lift-up storage feature, as it needs to withstand weight. |

| Sander (orbital or detail sander): For smoothing surfaces and preparing the wood for painting, ensuring a professional, flawless finish. Various grits will be needed. | Edge banding: Used to cover the exposed raw edges of plywood, giving a clean, furniture-grade appearance that mimics solid wood. |

| Paintbrush and roller: For applying primer and paint smoothly and evenly across all surfaces, ensuring a durable and attractive finish. | Wood filler: Essential for filling nail holes, minor imperfections, gaps, and seams before sanding and painting, creating a seamless surface. |

| Hinges: If you’re incorporating storage, quality hinges are needed for the lift-up seat tops. Consider heavy-duty or soft-close options for safety and longevity. | White semi-gloss paint and primer combo: A durable, easy-to-clean, and popular finish often chosen for banquettes in kitchens or dining areas. A combo product saves a step and ensures good adhesion. |

| Sandpaper (120 grit, 220 grit): Different grits for initial smoothing (120 grit for rough sanding) and fine finishing between paint coats (220 grit for smooth, professional results). |

Step-by-Step Process to Build Your Custom Banquette

1. Frame Building: Constructing the Foundation of Your Banquette

The frame is the skeleton of your banquette, providing crucial structural integrity. Accuracy at this stage is paramount for a stable and long-lasting custom seating solution.

- Cut 2×4 boards to size: Using your circular saw or table saw, cut the 2×4 lumber according to the precise length and depth measurements determined in your planning phase. Remember to cut pieces for the front, back, sides, and internal supports. Labeling pieces can help prevent confusion.

- Assemble the frames: Build two rectangular frames for your bench base – one for the bottom and one for the top. Ensure they are perfectly square by measuring diagonals (they should be equal). Use self-tapping screws (2.5-3 inches long) to securely join the 2x4s at each corner and for any internal cross-bracing. Consider adding a central support every 2-3 feet for longer banquettes to prevent any potential sagging over time.

- Attach legs and supports to the frames: Depending on your design, you can integrate legs into the frame structure or attach separate 2×4 vertical pieces at regular intervals (e.g., every 16-24 inches) along the length of the frame to serve as sturdy legs and supports for the top frame. Use multiple self-tapping screws per connection point for maximum stability, ensuring the structure can withstand daily use. This step ensures your banquette sits at the desired ergonomic height.

2. Outer Coverage: Enclosing the Structure with Plywood Sheathing

Once the frame is robust, it’s time to give your banquette its finished outer appearance with plywood sheathing, preparing it for the decorative trim and paint.

- Cut 1/4 inch plywood to size: Measure and precisely cut pieces of 1/4 inch plywood for the front, sides, and any exposed back areas of your banquette. These pieces will wrap smoothly around your 2×4 frame, providing a clean canvas.

- Attach plywood to the frame: Using a brad nailer, carefully attach the plywood panels to the 2×4 frame. Start by tacking the corners to hold them in place, then add nails every 6-8 inches along the studs and supports. Ensure the plywood is flush with the frame edges. Don’t be overly concerned with perfectly seamless edges at this stage; the trim work will cover and refine these later, giving a truly built-in and professional look to your custom dining bench.

3. Trim Work: Adding Refinement and Detail to Your Banquette

Trim transforms a basic box into a sophisticated piece of furniture, effectively hiding raw edges, covering imperfections, and adding significant character and a built-in feel to your banquette.

- Measure and cut 1×3 boards for trim: Precisely measure the lengths needed for your trim pieces. You’ll typically want trim along the top edge of the plywood panels, around the base (to mimic baseboards), and potentially on the corners. For a seamless look, use miter cuts (45-degree angles) where trim pieces meet at external corners, and coping joints for internal corners.

- Work around existing baseboards: A common challenge is integrating the banquette with existing wall baseboards. Instead of removing them, which can be messy, you can “cope” or “scribe” your banquette’s base trim to fit neatly around the existing wall trim. This method keeps your original baseboards intact and provides a truly custom, seamless fit.

- Add trim to inside and outside corners: Apply trim pieces to all exposed corners, both internal and external, using brad nails. This creates a clean, finished appearance and protects the plywood edges from everyday wear and tear, enhancing durability.

- Add trim to hide plywood edges: Specifically focus on adding trim to conceal the exposed 1/4 inch plywood edges on the ends and the back of the banquette (if it’s not positioned directly against a wall). This step significantly elevates the overall aesthetic and contributes to a professional, finished look.

4. Top Assembly: Crafting the Seating Surface and Storage Lids

The bench top needs to be strong, smooth, and, if desired, functional for storage. This is where your custom banquette seating truly comes together.

- Cut 3/4 inch plywood for bench top: This thicker plywood provides a robust and stable seating surface, essential for a comfortable and durable banquette. Cut it to fit precisely over your banquette frame. If you’re building a storage banquette, cut the top into sections that will serve as lift-up lids for easy access.

- Add edge banding to the front edge: Plywood edges can look unfinished and absorb paint unevenly. Apply iron-on edge banding to the front edge (and any other visible edges) of your bench top pieces. This creates a clean, smooth, and paintable surface that closely mimics solid wood, providing a high-quality finish.

- Fit pieces on top frame: Place your cut and edge-banded plywood pieces onto the top frame of your banquette. Ensure a snug fit with even gaps between any lid sections (if applicable). Do not attach them permanently yet if they are designed to be hinged for storage access.

5. Finishing Touches: Painting and Final Assembly

A good finish makes all the difference, providing durability, easy maintenance, and a professional, polished look to your custom banquette seating.

- Fill nail holes and imperfections: Before painting, meticulously fill all brad nail holes, any small gaps in your trim work, and minor surface imperfections with wood filler. Allow it to dry completely and sand smooth. This step is crucial for a flawless final appearance.

- Sand everything thoroughly: Once the filler is dry, sand all surfaces with 120-grit sandpaper. This coarse grit helps smooth out any rough spots, removes dried wood filler, and prepares the wood for primer. Pay close attention to corners and edges for a consistent texture.

- Apply paint coats with care: Start with a high-quality primer (or use your paint/primer combo) to ensure good adhesion and an even base. Apply the first coat, let it dry thoroughly, then lightly sand with 220-grit sandpaper to remove any raised grain or brush marks. Wipe clean and apply the second coat. Repeat this process for a third coat, ensuring a smooth, durable, and professional-looking finish.

- Let dry completely: Allow ample time for the paint to cure fully, especially before placing cushions or putting weight on the bench. This can take several days depending on humidity and paint type. Rushing this step can lead to dents, scratches, or uneven curing.

- Attach tops with hinges: If your banquette includes storage, carefully attach the 3/4 inch plywood tops to the frame using sturdy hinges. Position hinges evenly for smooth operation and ensure they are aligned correctly. Consider using soft-close hinges or lid supports to prevent slamming, enhance safety, and extend the life of your custom banquette with storage.

Your custom banquette structure is now complete and ready for comfortable cushions, making it a beautiful and functional addition to your dining area or kitchen!

Approximate Cost of Building DIY Banquette Seating

One of the most appealing aspects of a DIY banquette is the potential for significant cost savings compared to purchasing custom-built furniture or hiring a professional. Below is an approximate breakdown of material costs. Remember, these figures can fluctuate based on your geographical location, specific material choices (e.g., premium lumber vs. standard), and current market prices. This estimate assumes you already possess basic woodworking tools.

| Item Category | Item | Cost Range ($) |

|---|---|---|

| Basic Structural Materials | 2×4 lumber for robust framing and support structure | $30-40 |

| 1/4″ plywood for sides, back panels, and non-structural sheathing | $25-35 | |

| 3/4″ plywood for sturdy top/seat surface and any structural shelves | $45-55 | |

| 1×3 trim boards for finishing edges, decorative elements, and seamless integration | $20-30 | |

| Wood screws and nails (various sizes for different applications, including frame assembly and trim attachment) | $15-20 | |

| Essential Hardware | Hinges (4-6 pieces, particularly important for lift-up storage options, consider soft-close) | $20-25 |

| Brad nails (for nail gun, used for attaching plywood and trim quickly and discreetly) | $5-10 | |

| Self-tapping screws (essential for strong and reliable frame assembly) | $8-12 | |

| Finishing & Aesthetic Items | Paint and primer (high-quality, durable interior paint suitable for high-traffic areas, often a combo product) | $35-45 |

| Wood filler (for seamless surface preparation, filling holes and gaps) | $8-10 | |

| Sandpaper (various grits for smoothing, from initial sanding to fine finishing between coats) | $10-15 | |

| Edge banding (for covering raw plywood edges, providing a professional, finished appearance) | $10-15 | |

| Comfort & Upholstery Items (Optional but recommended for a complete banquette) | High-density foam padding (for comfortable and supportive seat cushions) | $40-60 |

| Upholstery fabric (durable and stylish fabric of your choice, consider stain-resistant options) | $30-50 | |

| Batting (adds softness, smooths out foam edges, and helps fabric lay nicely) | $15-20 | |

| Total Estimated Project Cost | $300-400 (excluding tools, assuming you have basic ones) |

Smart Money-Saving Tips for Your DIY Banquette Project

To keep your custom banquette project within budget without compromising quality, consider these smart money-saving strategies:

- Shop for Lumber Sales and Discounts: Always check local hardware stores, lumberyards, and even online marketplaces for ongoing sales, discounted “cull” piles, or reclaimed wood options. You can often find perfectly usable wood at a fraction of the cost for your banquette frame.

- Buy Materials in Bulk When Possible: If you plan on tackling multiple home improvement projects or building a larger banquette, purchasing lumber, plywood, or fasteners in larger quantities can often lead to volume discounts, reducing your per-unit cost.

- Scour for Fabric Remnants and Sales: For cushions and upholstery, visit fabric stores and check their remnant bins or clearance sections. You can often find high-quality, unique fabrics at significantly reduced prices, especially if your cushions are small or you can skillfully piece patterns together. Keep an eye out for seasonal sales.

- Utilize Leftover Paint and Supplies: If you have recently painted other rooms in your home, you might have leftover paint or primer that can be repurposed for your banquette. This not only saves on purchasing new paint but also ensures color consistency across your home. Similarly, check for leftover sandpaper or wood filler from previous projects.

Pro Tip for Materials: Prices are estimates and will vary based on your location, specific material choices, and local market conditions. I always recommend purchasing a small amount of extra material for each category. This prevents the need for inconvenient and time-consuming return trips to the store for a single missing screw or a short piece of trim, ultimately saving you time, gas, and stress during your custom banquette build.

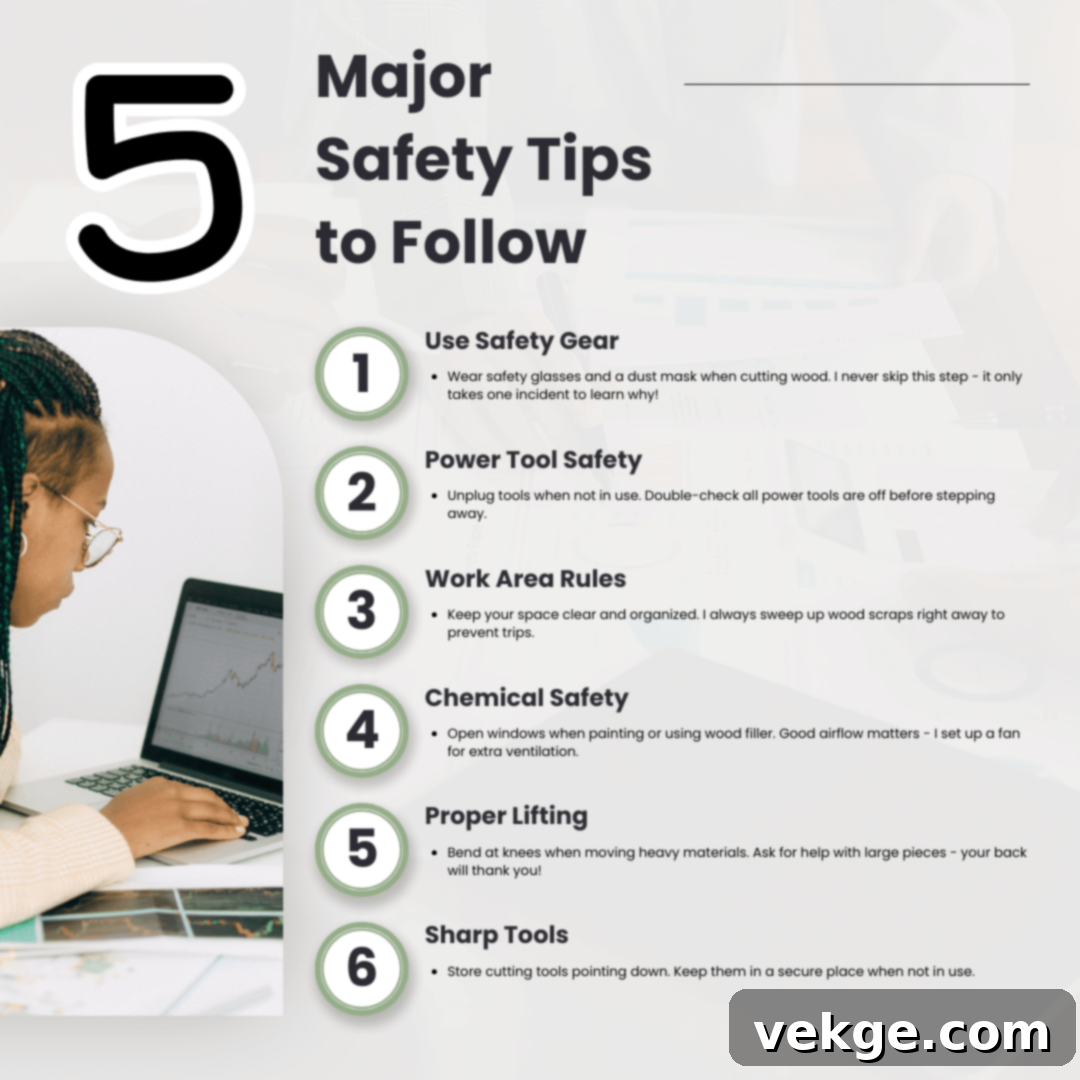

Important Safety Reminder: When working with power tools, always wear appropriate personal protective equipment (PPE) such as safety glasses, hearing protection, and sturdy gloves. Take a few extra minutes to review tool instructions, ensure blades are sharp, and set up a clean, well-lit, and stable working environment. This attention to safety can prevent accidents and save countless hours of trouble later, ensuring your DIY banquette project is completed safely and successfully.

Best Customization & Enhancement Ideas for Your Banquette Seating

Once you’ve mastered the basic build of your custom banquette seating, the real fun begins: customizing it to perfectly match your lifestyle, specific needs, and home decor. Here are some innovative ideas I’ve explored and loved, transforming a simple bench into a truly unique, highly functional, and aesthetically pleasing centerpiece for your kitchen or dining area.

Smart Storage Solutions to Maximize Space

Maximize the utility of your banquette by incorporating clever storage options, ideal for decluttering your dining or kitchen area, especially in small spaces.

- Lift-Up Seat Tops with Hydraulic Hinges: This is a classic and highly practical storage solution for a DIY banquette. Install heavy-duty hinges or, even better, hydraulic lid supports. These not only make opening and closing the seat tops effortless but also hold the lids open safely, preventing accidental slamming – a crucial feature, especially in homes with children or for frequent access.

- Integrated Pull-Out Drawers: Instead of or in addition to lift-up tops, design spacious pull-out drawers into the base of your banquette. These are excellent for storing placemats, napkins, cutlery, serving dishes, or even small toys, offering easy, convenient access without disturbing seated guests.

- Internal Storage Dividers or Bins: For optimal organization, add custom dividers or insert removable bins inside your storage compartments. These can be adjustable or fixed, helping you keep items neatly separated and easy to find, from craft supplies to seasonal decor or extra linens.

Enhanced Comfort Upgrades for a Lounging Experience

Transform your banquette from a purely functional bench into a supremely comfortable lounge area, inviting longer meals and relaxed conversations.

- Layered Foam Densities for Superior Seating: Don’t just use one type of foam. Layer different foam densities for the ultimate comfort. A firmer, high-density foam (e.g., 2.2-2.5 lb density) for the base provides essential support, while a softer, medium-density foam (e.g., 1.8-2.0 lb density) on top offers plush comfort. Finish with a layer of Dacron batting for a smooth, rounded look and added softness.

- Subtle Backrest Tilt (5-10 Degrees): For truly relaxed sitting, incorporate a slight backward tilt (around 5-10 degrees) into your backrest design. This ergonomic consideration dramatically improves comfort, making your banquette ideal for lingering conversations after dinner or extended family gatherings.

- Slightly Curved Backrest for Better Lumbar Support: Instead of a flat backrest, a subtle curve can provide superior lumbar support, conforming more naturally to the human back. This can be achieved by using flexible plywood or by carefully shaping the internal framing slightly during construction.

Stylish Add-ons for Aesthetic Appeal and Integration

Elevate the visual appeal of your banquette, making it a true centerpiece of your dining space and ensuring it seamlessly blends with your home’s existing decor.

- Integrated Under-Seat Lighting: Install LED strip lighting discreetly beneath the seat lip or along the kick plate. This creates a soft, ambient glow, perfect for evening dining, setting a mood, or simply adding a modern, sophisticated touch to your space.

- Washable Slipcovers for Practicality and Versatility: For busy family homes or banquettes in high-traffic areas like kitchens, washable slipcovers are a game-changer. They allow for easy cleaning of spills and stains and offer the flexibility to change your banquette’s look with minimal effort and cost, adapting to seasonal decor.

- Decorative Trim Molding for a Built-In Look: Beyond basic trim, add crown molding, picture frame molding, or beadboard panels to the base or sides of your banquette for a truly custom, furniture-grade finish that blends seamlessly with your home’s existing millwork and architectural style.

- Two-Tone Paint Scheme: Experiment with a two-tone paint scheme that complements your room’s existing color palette. For example, a darker base with a lighter top section can add depth, visual interest, and define different zones within your dining area.

Smart and Functional Features for Modern Living

Incorporate modern conveniences directly into your banquette design, making it even more practical for everyday life.

- Hidden Charging Ports: Install discreet USB charging ports or electrical outlets on the side of the banquette, integrated into the top trim, or even within a storage compartment. This is incredibly practical for charging phones, tablets, or small appliances while dining or working.

- Fold-Down Armrests: For banquettes that extend into a corner or are longer, consider adding fold-down armrests at the ends. These offer extra comfort when lounging and can be easily folded away to maximize seating space when more guests are present.

- Built-In Pet Feeding Station: If you have furry friends, integrate a small pull-out drawer or a recessed nook at one end of the banquette to house their food and water bowls. This keeps them neatly out of the way, prevents spills, and maintains a tidy dining area.

Diverse Material Options for Durability & Style

Choosing the right materials for your banquette’s exterior and upholstery is vital for both long-term durability and aesthetic appeal, especially in areas prone to wear and tear.

- Water-Resistant and Performance Fabrics: For family-friendly use, especially in kitchens, opt for water-resistant or high-performance fabrics. Materials like Sunbrella, Crypton, or treated polyesters are easier to clean and more resilient against spills, stains, and general wear.

- Outdoor Foam for Sunny Locations: If your banquette is situated near large windows and receives a lot of direct sunlight, consider using outdoor-grade foam for the cushions. This type of foam is specifically designed to resist breaking down from UV exposure and better withstands moisture, preventing mold and mildew.

- Stain-Resistant Upholstery: In high-traffic dining areas, selecting inherently stain-resistant materials like vinyl, leatherette, or specially treated fabrics will ensure your banquette maintains its pristine appearance for years to come, reducing maintenance efforts.

Quick Customization Tip: Before committing to a large-scale customization feature or an expensive material, test it out on a smaller scale or create a mock-up. This proactive approach can help you refine your ideas, confirm functionality, and prevent costly material waste, especially when experimenting with new techniques or unique materials for your custom banquette seating.

Addressing Common Challenges & Providing Effective Solutions for Your DIY Banquette

Even with meticulous planning, DIY projects can sometimes present unexpected hurdles. Knowing common challenges and their practical solutions beforehand can save you significant time, frustration, and money. Here’s a breakdown of issues you might encounter during your custom banquette build and how to effectively overcome them, ensuring a smooth and successful project.

Uneven Floors: The Wobble Factor for Your Banquette

- Problem: You’ve built your frame perfectly square and level, but once placed in your dining area, the bench wobbles or rocks on an uneven floor surface. This is a very common issue, particularly in older homes or with slight floor imperfections that are not immediately visible.

- Solution: The simplest solution is to use adjustable furniture feet or leveling glides. These can be easily screwed into the bottom of your banquette legs and individually adjusted to compensate for unevenness, ensuring a stable and level seat. Alternatively, for a more permanent fix, strategically place wood shims under the frame at the low spots. I’ve learned that checking the floor level with a long spirit level *before* starting construction and making preliminary adjustments can prevent this headache entirely.

Fitting Around Baseboards: Gaps and Seamless Integration

- Problem: You want your banquette to sit perfectly flush against the wall, but existing baseboards or skirting boards create an unsightly gap between the bench and the wall, disrupting the desired built-in aesthetic.

- Solution: You have two primary options for a clean fit. One is to carefully remove the section of baseboard where the banquette will sit, then reinstall it against the banquette’s side. However, I often prefer to “scribe” the banquette’s back panel or base trim to fit precisely around the existing baseboards. This involves carefully marking the profile of the baseboard onto your banquette material and then cutting it out with a jigsaw or coping saw. This method keeps your original baseboards intact and provides a truly custom, seamless fit.

Seat Height Issues: Is Your Banquette Too High or Too Low?

- Problem: After assembly, the banquette seat feels uncomfortable – either too high, making dining awkward and leaving your feet dangling, or too low, requiring an uncomfortable stretch to reach the table.

- Solution: This issue almost always stems from insufficient pre-planning for the cushion thickness. My golden rule is to test your desired seat height with your existing dining chairs and table *before* you even start cutting lumber for your DIY banquette. Calculate the total desired finished height (e.g., 18 inches) and then subtract the precise thickness of your planned cushion (e.g., 3-4 inches). The resulting measurement is the ideal height for your banquette’s bare frame. Always build the frame 2-4 inches shorter than the final desired height to allow for comfortable cushioning.

Storage Lid Weight: Preventing Accidental Slamming

- Problem: If you’ve included lift-up storage in your custom banquette, heavy plywood lids can be difficult to manage, posing a finger-pinching hazard and potentially damaging the frame if they slam down unexpectedly.

- Solution: Invest in high-quality hardware designed for this purpose. Install soft-close hinges, which slowly lower the lid without force, preventing slamming. Alternatively, use specialized lid supports or gas struts. These supports hold the lid open at various angles and gently guide it down when closed. While they might add a bit to the overall cost, they are invaluable for safety, functionality, and longevity, especially in a busy family environment.

Corner Alignment: Achieving Seamless Joints in L-shaped Banquettes

- Problem: When building an L-shaped or U-shaped banquette, achieving perfectly aligned and tight corner joints can be challenging, often leaving unsightly gaps or uneven seams.

- Solution: For inside corners, cut one piece of your framing lumber or plywood straight to meet the adjacent piece. Then, carefully measure and match-cut the joining piece to butt precisely against the first, ensuring a tight fit. For external corners, miter cuts (45-degree angles) provide the cleanest and most professional-looking joint. Always remember the carpenter’s adage: “Measure twice, cut once.” Dry-fit all your pieces before making permanent attachments to ensure everything lines up perfectly before fastening.

Paint Finish Problems: Eliminating Brush Marks and Ensuring Smoothness

- Problem: Despite careful painting, you might find unsightly brush marks, roller textures, or an uneven finish on your banquette, diminishing its custom appearance.

- Solution: Achieving a professional-looking paint finish requires patience and proper technique. Use high-quality foam rollers for large, flat surfaces, and a good-quality synthetic paintbrush for corners and detailed trim work. Apply paint in thin, even coats rather than attempting one thick coat. Crucially, lightly sand with fine-grit (220-grit) sandpaper between *each* coat. This removes any raised grain, minor dust, or brush marks and helps the subsequent coat adhere smoothly, resulting in a glass-like finish. Always clean dust thoroughly with a tack cloth before applying the next coat.

Conclusion: Enjoy Your Custom-Built Banquette Seating

Building a DIY banquette is more than just a home improvement project; it’s a smart, creative, and highly rewarding way to optimize your dining or kitchen area, bringing both unparalleled functionality and a personalized aesthetic to your home. By diligently following the detailed steps and expert tips I’ve shared from my own experience – from the initial precise planning and careful material selection to the robust construction and meticulous final finishing touches – you now have the comprehensive blueprint to create a truly bespoke seating solution that perfectly fits your space and needs.

For an approximate investment of around $300-$400 in materials (assuming you have basic woodworking tools readily available), you can achieve a high-end, custom-designed banquette seating area that would cost significantly more if purchased commercially or custom-built by professionals. This project not only enhances your living space and adds considerable value to your home but also provides immense satisfaction and pride in knowing you built it with your own hands, tailoring every detail to your preferences.

Remember, the key to a successful and rewarding DIY project is patience, attention to detail, and a commitment to quality. Do not rush through the crucial measurements, precise cutting, or the final finishing stages. Take your time, double-check your work, and truly enjoy the process of bringing your vision to life. Your effort will undoubtedly pay off with a beautiful, durable, and highly functional banquette that adds significant comfort, style, and efficiency to your home for many years to come.

Are you feeling inspired and ready to start your own custom banquette project? I’d absolutely love to hear about your progress, see your unique creations, and learn from your experiences! Share your journey and any specific challenges or triumphs in the comments section below. For further guidance on completing your project, you might also want to explore additional resources on selecting the perfect, most comfortable cushions and durable upholstery fabric to complement your new custom seating area, making it truly your own.

Your dream dining space, featuring comfortable and stylish custom banquette seating, is truly just a rewarding weekend project away – go for it!

Frequently Asked Questions About DIY Banquette Seating

What are the Best Materials for Comfortable Banquette Seating?

For ultimate comfort and durability in DIY banquette seating, focus on high-quality materials. Use high-density foam (typically 2.0-2.5 lb density) for the core of your seat cushions, as it provides excellent support and resists sagging over time. Layering this with a softer foam or Dacron batting can enhance plushness and give a smooth appearance. For upholstery, select durable, easy-to-clean fabrics such as performance fabrics (e.g., Sunbrella, Crypton), commercial-grade vinyl, or sturdy cotton/linen blends, especially if your banquette is in a high-traffic kitchen or dining area. The frame itself should be constructed from robust materials like furniture-grade plywood (birch or oak plywood) or solid hardwood (2×4 lumber is ideal for internal framing) to ensure long-lasting stability.

Is Banquette Seating Suitable for Small Kitchens or Dining Areas?

Absolutely, banquette seating is an exceptionally smart, highly recommended, and space-efficient solution for small kitchens or compact dining areas. It excels at maximizing usable space by utilizing often-underutilized corners or wall sections, creating a more efficient footprint than traditional chairs which require clearance on all sides. Furthermore, a well-designed custom banquette almost always includes integrated storage options beneath the seats, offering invaluable space for decluttering and organizing, which is a significant advantage in compact living spaces where every inch counts.

What is the Ideal Height for Banquette Seating for Dining Comfort?

The ideal finished seat height for banquette seating, including the cushion, is typically around 18 inches (46 cm) from the floor. This measurement aligns perfectly with the standard height of most dining chairs (usually between 17-19 inches), ensuring that your banquette can be comfortably used with a standard-height dining table (which usually sits around 30 inches / 76 cm high). When building the frame, it’s crucial to remember to account for the specific thickness of your chosen seat cushion to achieve this ideal final height.

How Deep Should a Banquette Seat Be for Optimal Comfort?

For optimal comfort and functionality, a banquette seat depth should range from 18 to 21 inches (46 to 53 cm). A depth of 18 inches is generally suitable for more upright dining and can be ideal for smaller spaces where every inch matters. A depth of 20-21 inches provides a more relaxed, lounge-like feel, allowing for deeper sitting and greater comfort, especially if you plan to use the banquette for extended periods. This range ensures enough space for comfortable seating without making the banquette too deep to access the table easily or taking up excessive floor space in your room.

How Can I Add a Backrest to My Banquette for Enhanced Support and Style?

Adding a backrest significantly enhances both the comfort and provides an excellent opportunity for additional style and customization for your banquette. To do this, extend your banquette’s internal frame upward from the back of the seat, creating a vertical support structure. Attach a sturdy plywood panel (e.g., 3/4 inch or 1/2 inch thick) to this extended frame to create the solid backrest structure. Then, apply high-density foam padding to this plywood back, shaping it as desired (e.g., slightly tilted backward for ergonomics or subtly curved for better lumbar support). Finally, upholster the entire backrest with your chosen fabric, ensuring it’s securely attached for both maximum comfort and a polished, professional aesthetic.