Why Does Your Floor Vibrate When the Furnace Kicks In? A Comprehensive Troubleshooting Guide

That subtle rumble beneath your feet, the unsettling shake that accompanies the click and hum of your heating system—if you’ve noticed your floor vibrating when the furnace kicks in, you’re not alone. This phenomenon, while often a minor annoyance, can sometimes signal deeper issues within your home’s crucial heating system. Understanding the mechanics behind these vibrations is the first step towards a quieter, more efficient, and ultimately, a more comfortable home.

This comprehensive guide delves into the intricate world of home heating, exploring the common causes behind these curious vibrations, offering practical DIY troubleshooting steps, and outlining when it’s time to call in the professionals. Our aim is to demystify this common household occurrence, empowering you to identify the problem and take appropriate action, ensuring your sanctuary of warmth and peace remains undisturbed throughout the colder months.

Understanding Your Home Heating System: The Heart of Home Comfort

At the core of a cozy home during chilly seasons lies the heating system, with furnaces typically playing a pivotal role. The journey of warmth begins when your thermostat, acting as your home’s climate control, detects a drop in temperature below your set point. This triggers a signal to your furnace, prompting it to initiate its heating cycle.

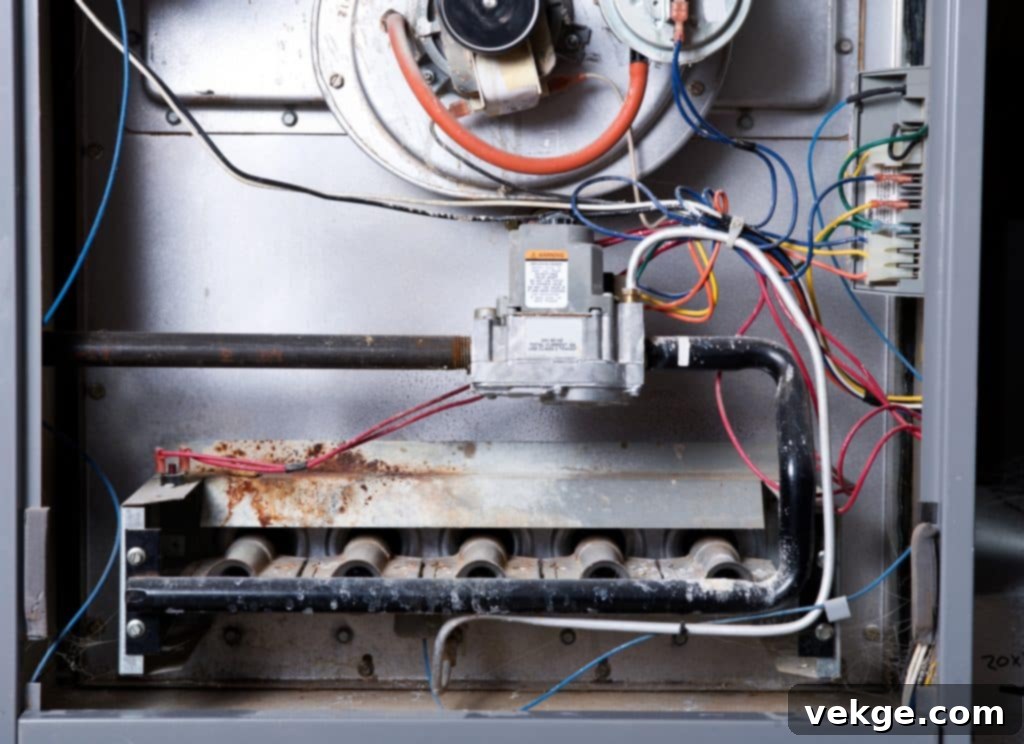

Inside the furnace, a series of complex operations unfolds. For gas furnaces, this involves the ignition of fuel within a combustion chamber, while electric furnaces use heating elements. The generated heat warms air, which is then pushed by a powerful blower motor through an intricate network of ductwork, distributing it throughout your living spaces. This basic understanding of your furnace’s operation—from thermostat call to warm air delivery—is fundamental. It establishes a baseline for what normal sounds and sensations accompany a functioning furnace, allowing you to easily identify when something, such as unexpected floor vibrations, deviates from the norm.

A well-maintained heating system should operate smoothly, producing consistent warmth with minimal noise and no noticeable vibrations. When these vibrations occur, it suggests an imbalance or obstruction somewhere in this carefully orchestrated process, warranting further investigation to prevent potential energy inefficiencies or more serious mechanical failures.

Common Causes of Floor Vibrations When the Furnace Turns On

The vibrations you experience are more than just your home’s response to warmth; they are often symptomatic of underlying issues within your heating system. Identifying the root cause is crucial for effective troubleshooting. Here are some of the most common culprits:

1. Initial Air Rush and Ductwork Issues

When the furnace blower first activates, a sudden rush of air is pushed through the ductwork. If ducts are loose, improperly secured, or have insufficient insulation, this sudden air pressure can cause them to expand, contract, or rattle against joists and other structural elements, transmitting vibrations through your floors. This is particularly common in older homes or systems that have been dormant for an extended period, allowing fittings to loosen.

2. Imbalanced Blower Wheel

The blower wheel (or fan) is responsible for moving air through your system. Over time, dirt, dust, and debris can accumulate unevenly on the blower blades, throwing the wheel off balance. A bent blade or a loose set screw can also cause imbalance. An imbalanced blower wheel spins eccentrically, creating significant vibrations that resonate throughout the furnace unit and into your home’s structure.

3. Motor Problems and Worn Components

The blower motor itself can be a source of vibrations. Worn bearings in the motor can cause grinding or rattling noises and excessive vibration. Additionally, deteriorated motor mounts (the rubber or spring components that isolate the motor’s vibration from the furnace casing) can fail, allowing motor vibrations to transfer directly to the furnace and then to the floor.

4. Dirty Air Filter

A clogged or excessively dirty air filter restricts airflow, forcing the blower motor to work harder to pull air through. This increased strain can lead to overheating, motor issues, and amplified vibrations. It can also create negative pressure within the ductwork, causing sections to flex and vibrate.

5. Gas Ignition Problems

For gas furnaces, delayed ignition can cause a small “boom” or sudden burst of flame as accumulated gas ignites. This mini-explosion can create a jolt or vibration that can be felt through the floor. While less common, it’s a serious issue that requires immediate professional attention.

6. Improper Furnace Installation or Leveling

If the furnace unit itself is not installed on a level surface or is not adequately secured to its base, its normal operational vibrations can be amplified and transferred directly to the floor. Similarly, if there isn’t sufficient isolation between the furnace and the surrounding structure, vibrations can easily propagate.

7. Undersized or Over-pressurized Ductwork

Ductwork that is too small for the volume of air being moved by the furnace can lead to excessive air velocity and pressure. This can cause the ducts to flex and vibrate, especially at bends or connection points. Even properly sized ducts can vibrate if the airflow is excessively high due to a powerful blower or certain system settings.

Furnace Operation and Maintenance: Your First Line of Defense

Regular maintenance is not just about keeping your furnace running; it’s your primary strategy against a host of issues, including bothersome vibrations, reduced efficiency, and premature breakdowns. Proactive care ensures that your home heating system operates smoothly and quietly.

The Importance of Annual Professional Tune-Ups

Scheduling annual check-ups by a qualified HVAC professional is paramount. During these routine inspections, technicians perform a series of critical tasks designed to optimize furnace performance and prevent problems:

- Blower Motor Inspection and Lubrication: They will check the blower motor for signs of wear, lubricate moving parts (if applicable), and ensure it’s operating efficiently and quietly.

- Blower Wheel Cleaning and Balancing: A thorough cleaning removes accumulated dirt and debris, which can cause imbalance. If necessary, they can balance the blower wheel to eliminate vibration.

- Ductwork Inspection: Professionals will check for loose connections, leaks, and signs of rattling in the ductwork, tightening or sealing as needed.

- Component Check: All internal components, from the heat exchanger to electrical connections, are inspected for optimal condition, wear, or potential hazards.

- Air Filter Replacement: While homeowners can do this, technicians will ensure the correct filter type is used and that airflow is not restricted.

- Gas Pressure and Ignition System Check: For gas furnaces, these checks are crucial for safe and efficient operation, helping prevent delayed ignition issues.

This comprehensive approach not only significantly reduces the risk of vibrations but also enhances the overall efficiency and extends the lifespan of your heating system. A well-maintained furnace consumes less energy, saving you money on utility bills, and provides more consistent, reliable heating.

DIY Preventative Measures: Keeping Things Smooth Between Visits

While professional tune-ups are essential, there are simple steps homeowners can take:

- Regular Air Filter Changes: Check your air filter monthly and replace it every 1-3 months, depending on usage, pet presence, and allergies. A clean filter ensures proper airflow, reducing strain on the blower motor and preventing many vibration-related issues.

- Keep Furnace Area Clear: Ensure the area around your furnace is clean and free of obstructions. This allows for proper airflow and easier access for maintenance.

Troubleshooting Furnace-Related Vibrations: A Step-by-Step Guide

Identifying the precise source of vibrations can sometimes be a straightforward process; other times, it demands a more methodical approach. Before attempting any inspection, always ensure the furnace is turned off at the thermostat and the main power switch for safety.

DIY Inspection Steps:

- Listen and Observe: Pay close attention to the sound and feel of the vibration. Is it a gentle hum, a distinct rattle, or a heavy thud? Does it occur immediately when the furnace kicks on, or after a few moments? Pinpointing the timing and nature of the vibration can provide valuable clues.

- Check the Air Filter: This is the simplest and often most overlooked solution. A clogged filter restricts airflow, putting strain on the blower motor and potentially causing vibrations. Replace it if it’s dirty.

- Inspect Furnace Panels and Covers: Over time, the screws securing the access panels or covers on your furnace can loosen due to constant vibration. Gently press on different panels while the furnace is running (safely away from moving parts) to see if the vibration lessens. Tighten any loose screws with a screwdriver.

- Examine the Ductwork: Follow the main ducts radiating from your furnace. Look for any loose connections, gaps, or areas where ducts might be rattling against floor joists, walls, or other ducts. You might notice metal clanking sounds. Secure loose sections with metal screws or foil tape for HVAC applications. If a duct is vibrating against a wooden beam, a small piece of rubber or felt padding can often resolve the issue.

- Check for Objects Near the Blower: With the power completely off, open the blower compartment (consult your owner’s manual for access). Carefully check for any foreign objects that might have fallen into the blower wheel or casing, such as small toys, debris, or even loose insulation. Remove anything that doesn’t belong.

- Assess the Furnace Leveling and Mounting: Visually inspect if your furnace unit appears level. If it’s noticeably off, or if it seems poorly mounted, this could be contributing to the issue. This might be a job for a professional, but a quick visual check can help diagnose.

If these initial steps don’t resolve the issue, or if you’re uncomfortable performing any of these checks, it may be time to consult a professional. More complex problems, like an unbalanced blower wheel, worn motor bearings, or issues with the furnace’s internal installation, typically require specialized tools and expertise.

Professional Solutions and Preventative Measures

While many minor vibration issues can be addressed through DIY troubleshooting, certain problems demand the expertise of a certified HVAC technician. Attempting to fix complex internal furnace components without proper training can be dangerous and may void your warranty. Professional intervention ensures both safety and the correct, lasting solution.

When to Call a Professional:

- Blower Wheel Balancing or Replacement: If a dirty or damaged blower wheel is causing vibrations, a technician can meticulously clean and balance it. In cases of severe damage (e.g., bent blades), the entire blower wheel may need replacement.

- Motor Repair or Replacement: Worn-out blower motor bearings, a failing motor, or issues with motor mounts require professional assessment and repair or replacement to restore smooth operation.

- Ductwork Reinforcement and Repair: Beyond simple tightening, a professional can assess your entire ductwork system for structural integrity, airflow issues, and resonant frequencies. They can reinforce loose sections, seal leaks, and ensure proper sizing and routing to prevent vibrations.

- Gas System Inspection: Any suspected issues with gas ignition, burners, or gas lines are critical and must be handled by a licensed professional to ensure safety.

- Furnace Leveling and Isolation: If the furnace itself is unstable or improperly isolated from the floor, a technician can level the unit and install appropriate anti-vibration pads or mounts.

- Internal Component Issues: Problems within the heat exchanger, combustion chamber, or other core components, which might indirectly cause vibrations, are exclusively within a professional’s scope.

Long-Term Preventative Measures:

To avoid future vibrations and ensure the longevity of your heating system, incorporate these preventative measures:

- Annual Professional Maintenance: As highlighted earlier, this is the most effective preventative step, catching small issues before they escalate.

- Regular Filter Changes: Consistently replacing your air filter ensures optimal airflow, reduces strain on the blower, and minimizes dirt accumulation on internal components.

- Duct Cleaning: Periodic professional duct cleaning can remove significant buildup of dust and debris, which can otherwise contribute to reduced airflow and potential blower imbalance.

- Consider System Upgrades: If your furnace is very old and frequently develops issues, investing in a newer, more efficient model can drastically reduce noise and vibration, while also offering better energy performance.

Reducing Furnace Noise and Vibrations: Advanced DIY and Comfort Enhancements

Beyond fixing the root cause of vibrations, there are several measures homeowners can take to further minimize furnace noise and enhance overall home comfort. These can be particularly useful even after addressing mechanical issues, for those seeking a truly quiet heating system.

- Install Anti-Vibration Pads: Place specialized rubber or cork anti-vibration pads directly under the furnace unit. These pads absorb mechanical vibrations before they can transmit into the floor and structural elements of your home. Ensure the furnace is still level after installation.

- Secure Loose Panels and Screws: Regularly check and tighten all accessible screws, bolts, and panels on the furnace casing and around the ductwork. Even minor looseness can lead to annoying rattles when the system is operating.

- Insulate Ductwork: Applying external insulation to your ductwork can serve multiple purposes. It not only reduces heat loss (improving efficiency) but can also dampen the sound of rushing air and minor duct vibrations. Ensure insulation doesn’t block any vents or access points.

- Seal Duct Leaks: Use specialized mastic sealant or metallic foil tape (not duct tape!) to seal any leaks in your ductwork. Leaks can cause whistling noises, reduce system efficiency, and disrupt airflow, potentially contributing to vibrations.

- Check Blower Motor Alignment and Belts (if applicable): For older belt-driven blowers, inspect the belt for wear, cracks, or looseness, and ensure proper tension. Also, check that the motor and blower pulleys are correctly aligned. This is a task that may require professional assessment if you are unsure.

- Consider Acoustic Enclosures: In some cases, building a sound-dampening enclosure around the furnace unit (ensuring proper ventilation and access for maintenance) can significantly reduce noise transmission to living areas. This often requires professional design to ensure safety and code compliance.

- Regular Filter Maintenance: We can’t stress this enough. A clean filter isn’t just for efficiency; it helps maintain steady airflow, preventing your blower from working overtime and reducing unnecessary strain and potential vibrations.

Implementing these measures can transform a noisy, vibrating furnace into a discreet, highly efficient component of your home’s comfort system. A quiet heating system contributes significantly to the peaceful ambiance of your living space.

Conclusion: Reclaiming Your Home’s Peace and Warmth

If you’ve noticed your floor vibrating when your furnace turns on, it’s not merely an eccentric quirk of your home that you should passively endure. This phenomenon, while not uncommon, serves as an important signal—a reminder that it’s time to pay closer attention to the health and performance of your home’s heating system. Addressing these vibrations is not just about eliminating an annoyance; it’s about ensuring the longevity, efficiency, and safety of one of your home’s most vital appliances.

Whether the solution lies in performing a few simple DIY checks yourself—like replacing a dirty air filter or tightening a loose panel—or in calling in the experts for a thorough inspection and specialized repair, taking action is paramount. Ignoring persistent vibrations can lead to diminished heating efficiency, higher energy bills, and potentially more severe mechanical failures down the line. A prompt response can lead to not only a quieter, more stable floor but also a more efficient, reliable, and safer furnace.

Remember, the comfort, warmth, and safety of your home during the colder months hinge significantly on the optimal health of your heating system. Don’t let minor issues evolve into major, costly problems. Address those furnace vibrations today, and ensure your home remains the warm, welcoming, and peaceful sanctuary it truly should be.