Mastering Industrial Noise: The Comprehensive Guide to Soundproofing Insulation for Enhanced Safety and Productivity

In the bustling world of industry, where heavy machinery hums and manufacturing processes churn, excessive noise is an omnipresent challenge. Far from being a mere inconvenience, this pervasive noise pollution can significantly degrade worker productivity, pose serious safety risks, and lead to costly legal compliance issues. From the roaring engines of equipment to the constant drone of HVAC systems, unchecked sound reverberates throughout a workspace, impacting both employees and the surrounding environment. Implementing proper soundproofing insulation isn’t just an option; it’s a critical investment for cultivating a quieter, more efficient, and ultimately safer industrial setting.

However, navigating the vast market of acoustic solutions can be daunting. You might find yourself asking, “Where can I truly find the most effective soundproofing insulation for industrial use?” The journey to an optimally sound-controlled environment requires selecting the right materials and identifying reliable suppliers. Whether your needs involve high-density acoustic panels, specialized sound-absorbing foam, or robust barriers designed for heavy machinery, making informed decisions is paramount. This comprehensive guide will illuminate the best sources for industrial soundproofing insulation, detail crucial considerations when making your purchase, and outline strategies to ensure the long-term effectiveness of your noise reduction efforts.

Factors to Consider When Choosing Industrial Soundproofing Insulation

Industrial soundproofing is not a one-size-fits-all solution. Selecting the appropriate insulation for a demanding industrial environment necessitates a thorough evaluation of various factors. The overall success and efficacy of your noise control strategy hinge on understanding the nature of the noise, the inherent properties of the insulation materials, and the specific requirements for installation and maintenance. Here are the pivotal aspects to keep in mind:

- Noise Reduction Coefficient (NRC) and Sound Transmission Class (STC): These two metrics are fundamental to understanding a material’s acoustic performance. The Noise Reduction Coefficient (NRC) quantifies a material’s ability to absorb sound, indicating how much sound energy it can soak up rather than reflect. A higher NRC value signifies better sound absorption, crucial for reducing echoes and reverberation within a space. Conversely, the Sound Transmission Class (STC) measures a material’s capacity to block airborne sound from passing through it, typically applicable to walls, floors, and ceilings. A higher STC rating indicates superior sound blocking capabilities. For optimal industrial soundproofing, materials with high ratings in both NRC and STC are often preferred, as they effectively address both internal reverberation and external sound leakage.

- Type of Noise: Identifying the predominant type of noise is crucial for selecting the right insulation.

- Airborne Noise: This category includes sounds that travel through the air, such as human voices, alarms, music, or the continuous hum of machinery and HVAC systems. Effective control of airborne noise requires insulation materials designed to absorb sound waves or create a barrier to their propagation.

- Structure-borne Noise: This type of noise originates from vibrations that transmit through solid structures, such as when heavy equipment impacts the ground, a machine vibrates against a concrete floor, or pipes transmit fluid-borne vibrations. Addressing structure-borne noise demands specialized vibration-damping materials like resilient channels, heavy-duty rubber mats, composite barriers, or isolation mounts that decouple vibrating components from the main structure. Often, a combination of solutions is needed to tackle complex industrial noise profiles.

- Fire Resistance and Compliance with Regulations: Safety is paramount in industrial environments. Many facilities operate under stringent fire safety codes, necessitating insulation materials that meet specific fire-resistant regulations. Materials such as mineral wool and fiberglass are highly favored not only for their excellent soundproofing benefits but also for their inherent fire-resistant properties. Always ensure that any chosen insulation material complies with local building codes, industry-specific safety standards (e.g., OSHA, NIOSH), and environmental regulations.

- Durability and Maintenance Requirements: Industrial settings are inherently harsh environments, often characterized by extreme temperatures, high humidity, dust, and exposure to various chemicals. Your soundproofing insulation must be robust enough to withstand these challenging conditions without deteriorating. It should resist moisture ingress, chemical corrosion, heavy impact, and continuous exposure to vibration. Furthermore, considering the ease of maintenance and potential for replacement is vital; materials that are easy to clean, repair, or replace can significantly reduce long-term operational costs and downtime.

- Installation Complexity and Compatibility: The ease and feasibility of installation are practical considerations. Some advanced soundproofing systems may require specialized tools or professional expertise for correct installation, ensuring optimal performance and safety. Other materials are designed for simpler application, potentially allowing for in-house installation with minimal effort. It’s essential to assess the material’s compatibility with existing structures, machinery, and facility layout, taking into account any space constraints or operational disruptions during the installation process.

- Cost vs. Long-Term Effectiveness and ROI: While budget is always a significant factor, opting for the cheapest materials can often compromise effectiveness and lead to higher costs in the long run due to premature wear, inadequate noise reduction, or the need for frequent replacement. When evaluating price, consider the initial investment against the material’s expected lifespan, its performance guarantees, and the potential for long-term operational savings. High-quality soundproofing can lead to increased worker productivity, reduced health-related costs, enhanced safety compliance, and even improved energy efficiency if the insulation also offers thermal benefits, providing a strong return on investment.

Options for Industrial Soundproofing Insulation: Top Suppliers

Finding the right supplier is as crucial as selecting the right material. Many excellent retailers specialize in acoustical solutions suitable for diverse industrial settings. Here are some of the leading companies offering industrial soundproofing insulation:

Soundproof Cow

For a comprehensive approach to noise control, encompassing both soundproofing and sound absorption, Soundproof Cow stands out as a premier destination. They offer tailored soundproofing modalities for a wide array of spaces, including residential, commercial, hospitality, industrial environments, and even DIY solutions. Their sound absorption products are ideal for large industrial spaces plagued by reverberation and echo, which can significantly amplify overall noise levels. Simultaneously, their acoustic options are designed to enhance speech clarity and provide precise acoustic treatment, vital for communication in busy factory floors or control rooms. If you’re uncertain about the best solution for your facility, Soundproof Cow provides an online questionnaire to help assess your specific needs and guide you toward the optimal choice. For large-scale projects or bulk orders, they also offer attractive volume discounts, though direct contact is required as such orders cannot be completed online, ensuring personalized service for complex industrial requirements.

DDS Acoustical Specialties

DDS Acoustical Specialities is a renowned provider of noise control solutions across multiple industries, with a significant focus on industrial soundproofing and noise control. Their extensive range of noise control and soundproofing products are meticulously designed to meet stringent OSHA and NIOSH regulations, making them exceptionally well-suited for demanding industrial environments and manufacturing sites. DDS prides itself on delivering custom-engineered solutions for unique industrial soundproofing challenges. They specialize in both occupational and outdoor soundproofing offerings, demonstrating a deep understanding of the specific acoustic profiles of various industrial machines to ensure that noise reduction strategies do not impede operational efficiency. For those interested in their bespoke services, their website features a convenient online quote request tool.

Netwell Noise Control

Netwell Noise Control offers a comprehensive suite of acoustic solutions, including commercial acoustics, industrial noise control, residential soundproofing, and a wide variety of wall panels tailored to fit every space. Their process typically begins with a complimentary room analysis where you provide detailed specifications and descriptions of your facility to allow their experts to accurately determine your specific soundproofing needs. With a proven track record of serving prominent clients such as Nestle, Goodyear, and Target, Netwell Noise Control has earned widespread trust across diverse industries for various soundproofing requirements. A key advantage they offer is a range of self-installing soundproofing panels. This option is particularly beneficial for businesses operating with tighter budgets, allowing them to save on installation costs without compromising on product quality, and providing greater control over project timelines.

Rockwool A/S

If your industrial facility requires more than just soundproofing—demanding robust heat, fire, and corrosion protection for your employees—then Rockwool A/S is an ideal partner. They offer an extensive range of industrial insulation options, specifically their ProRox stone wool range. This innovative stone wool is engineered to provide multi-functional benefits, assisting industries both inland and in challenging offshore or marine environments. Rockwool A/S asserts that their stone wool is among the most effective insulation materials globally, designed for exceptional longevity. The company confidently guarantees that their products will not deteriorate over time, maintaining their structural integrity and performance from the very first day of installation throughout their impressive lifespan.

All Noise Control, LLC

All Noise Control positions itself as a comprehensive, one-stop shop for diverse sectors, from government spaces to industrial and manufacturing facilities. They provide high-quality soundproofing solutions for music studios, hospitality venues, healthcare facilities, and construction sites, all while maintaining a strong commitment to efficiency and product quality. For clients seeking a balance between rigid and flexible noise control solutions, All Noise Control offers an excellent array of choices. Their popular sound curtains and acoustic blankets can be deployed either independently for targeted noise reduction or integrated as a vital component within a larger, more complex soundproofing system. Furthermore, they excel in custom soundproofing options, including specialized view windows, grommets, robust rooftop panels, sliding hinged and overhead doors, industrial silencers, and high-performance exhaust fans, ensuring bespoke solutions for unique industrial challenges.

Isotech, Inc.

With an impressive legacy stretching back to 1982, Isotech, Inc. brings decades of expertise to the fields of noise control, soundproofing, insulation, and specialized testing chambers. They are particularly adept at addressing all facets of soundproofing needs and applications specifically aimed at significantly reducing noise levels within the industrial sector. Isotech’s product portfolio is extensive, featuring everything from advanced acoustical foam to soundproofing panels, sound deadening materials, and various forms of insulation. Their long-standing experience allows them to provide unparalleled service, accurately assessing customer needs and meticulously crafting solutions that empower businesses to elevate their operational efficiency and compliance to the next level.

Kingspan Group

While the core specialization of Kingspan Group may not be solely in soundproofing, their extensive experience in high-performance building insulation for energy efficiency makes them highly adept at insulating for effective noise reduction. A significant aspect of Kingspan Group’s mission is their profound commitment to sustainability. Therefore, if your objective is to mitigate noise pollution within your industrial facility while simultaneously enhancing energy efficiency and reducing your environmental footprint, Kingspan Group emerges as an exceptionally fitting partner, offering solutions that deliver both acoustic comfort and ecological responsibility.

O’Neill Engineered Systems, Inc.

In stark contrast to companies with broader focuses, O’Neill Engineered Systems dedicates its primary efforts to noise reduction, making them a specialized and innovative provider of soundproofing options tailored for industrial needs. They pride themselves on tackling complex acoustic challenges that others cannot resolve, often stepping in to rectify previous unsatisfactory soundproofing attempts. Their team is committed to delivering quality that clients can unequivocally trust and providing a level of service that genuinely differentiates them in the market. O’Neill Engineered Systems’ comprehensive sound reduction inventory includes specialized acoustic doors and windows, fully enclosed structures for noisy machinery, aesthetic fabric-wrapped acoustic panels, versatile sound curtains and blankets, precision acoustic test chambers, and robust sound barrier walls, offering a complete spectrum of industrial noise control solutions.

Knauf Insulation

Knauf Insulation, a prominent, family-owned fiberglass insulation manufacturer, also offers remarkable soundproofing capabilities, leveraging its vast experience and high-quality product lines. While not exclusively focused on acoustic insulation, their products provide incredible soundproofing solutions due to their superior design and material composition. Knauf Insulation delivers a diverse range of thermal and acoustic insulation options, always with a keen focus on sustainability and utilizing recycled content, making them an excellent choice for environmentally conscious industrial clients seeking reliable noise control and energy efficiency.

Environmental Noise Control

Environmental Noise Control operates as a full-service acoustical engineering company, providing comprehensive soundproofing solutions through a meticulously designed seven-step process. This systematic approach ensures that every aspect of your noise control needs is thoroughly addressed. First, their expert staff will meticulously assess the source and nature of the noise within your facility. Following this, they will conduct precise measurements to establish a baseline noise level, culminating in a detailed report of their findings. The firm then presents a range of customized options best suited for your specific space, fostering a collaborative environment to develop a clear plan of action. Once you have finalized your preferred solution, Environmental Noise Control manages the installation and rigorously tests the implemented soundproofing system. This crucial testing phase confirms whether the solution effectively mitigates the sound issue and ensures full compliance with all pertinent safety regulations. Upon successful completion of all these steps, your industrial soundproofing will be fully optimized and ready to deliver a quieter, safer environment.

How Can Industrial Environments Use Soundproofing Insulation?

Industrial environments are inherently dynamic and often noisy, characterized by the operation of heavy machinery, active production lines, complex ventilation systems, and large equipment. While a certain level of operational sound is unavoidable, excessive noise transcends mere annoyance; it poses significant risks, including permanent hearing damage, substantial reductions in worker productivity and concentration, and potential non-compliance with critical workplace safety regulations. This is precisely where soundproofing insulation becomes indispensable. Depending on its material composition and design, soundproofing insulation actively controls noise levels by either absorbing sound waves, preventing their reflection and echo, or by blocking the transmission of sound from one area to another.

In the majority of industrial settings, achieving optimal results typically involves a synergistic combination of both sound absorption and sound blocking techniques. For instance, a manufacturing facility might employ specialized vibration-damping materials directly on machinery to effectively reduce structure-borne noise, which originates from mechanical vibrations. Simultaneously, acoustic panels could be strategically installed on walls and ceilings to absorb airborne noise, such as the general hum of operations or shouting, thereby minimizing reverberation and creating a more audibly comfortable workspace. This multi-faceted approach ensures that both the source of the noise and its propagation throughout the environment are comprehensively managed, leading to a significantly quieter, safer, and more productive industrial space.

Types of Soundproofing Insulation for Industrial Use

Industrial environments generate a wide spectrum of noise types, each demanding a specific approach to control. Therefore, selecting the most effective soundproofing insulation hinges on accurately identifying the type of noise you need to mitigate and understanding the structural characteristics of your workspace. Here are the most effective and commonly utilized insulation materials tailored for industrial soundproofing applications:

- Acoustic Panels: Crafted from highly sound-absorbing materials, acoustic panels are invaluable for controlling echo and reverberation, particularly in large, open industrial spaces like factory floors or warehouses. They are also widely deployed in areas where speech clarity is paramount, such as control rooms, offices adjacent to production lines, or assembly areas where communication is critical for safety and efficiency. These panels capture sound waves, preventing them from bouncing off hard surfaces and thereby reducing overall noise levels and improving acoustic comfort.

- Mass-Loaded Vinyl (MLV): This material is a dense, yet flexible, vinyl barrier celebrated for its exceptional effectiveness in blocking airborne noise. Often installed within walls, ceilings, floors, and machinery enclosures, MLV significantly impedes sound transmission, preventing noise from traveling between different sections of a facility or escaping into the surrounding environment. Its high mass per square foot makes it an excellent sound barrier, and it integrates seamlessly with other insulation materials to create multi-layered, high-performance acoustic solutions.

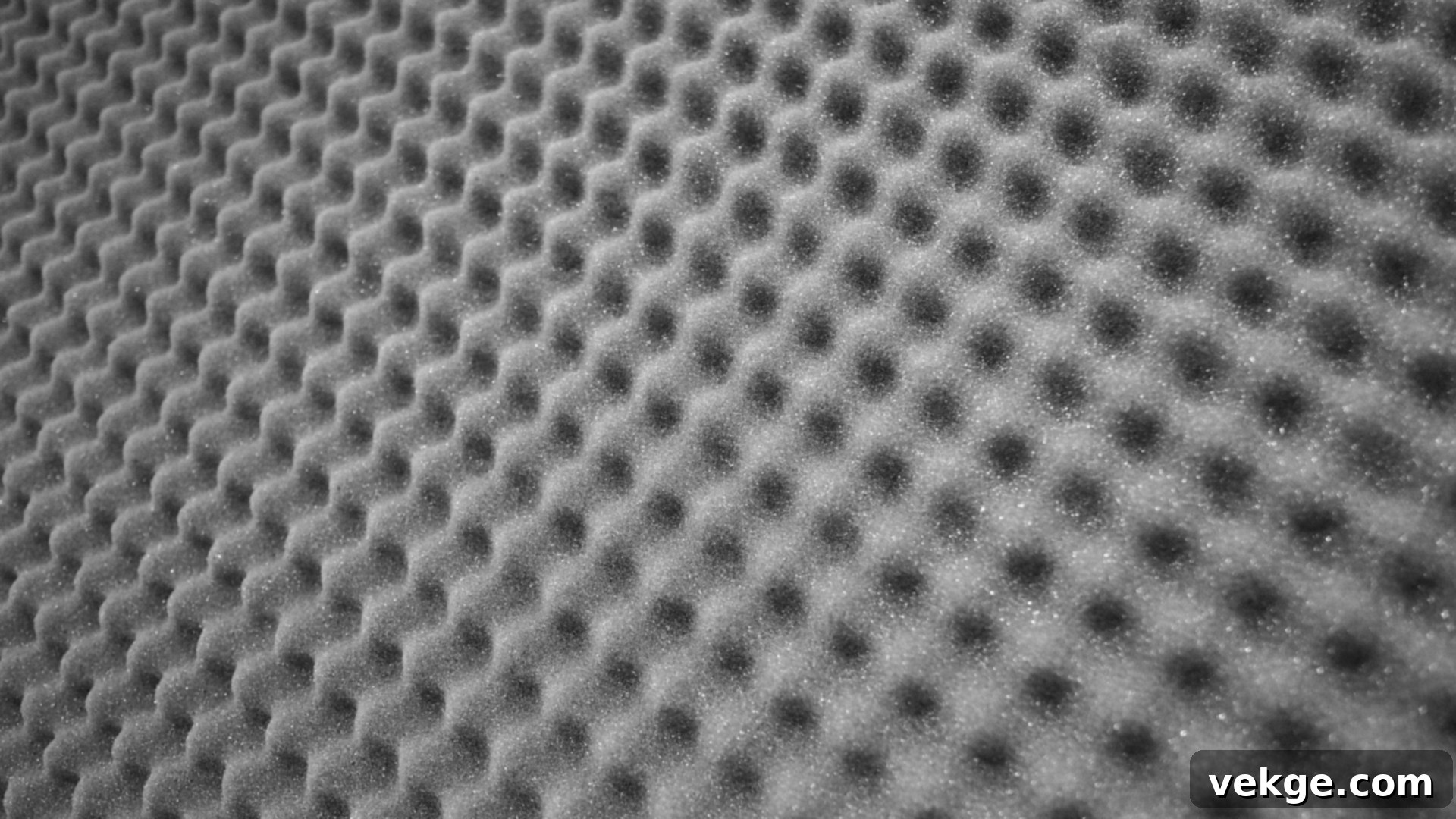

- Foam Insulation: Including varieties like polyurethane foam, melamine foam, and specialized acoustic foam panels, this type of insulation excels at sound absorption. It is particularly effective at mitigating echoes and dampening high-frequency noises, creating a more controlled acoustic environment. Foam insulation finds frequent application in engine rooms, manufacturing plants, and within custom-built industrial soundproof enclosures where targeted sound absorption is required to protect workers and sensitive equipment.

- Mineral Wool and Fiberglass Insulation: These robust materials offer a powerful dual benefit: they provide excellent acoustic insulation alongside superior thermal insulation properties. They are commonly installed within wall cavities, ceilings, and floors not only to reduce noise transmission but also to enhance energy efficiency, helping to regulate internal temperatures. Their inherent durability and fire-resistant characteristics make them an ideal choice for high-temperature industrial environments where safety and longevity are paramount.

- Multi-Layered Solutions: For the most challenging and high-noise industrial settings, such as power plants, heavy machinery workshops, or active production facilities, multi-layered soundproofing solutions are often the optimal choice. These comprehensive systems combine several different soundproofing materials—such as mass-loaded vinyl for blocking, foam for absorption, and fiberglass or mineral wool for both—to achieve maximum noise control. By strategically layering these materials, multi-layered solutions deliver both superior sound absorption and robust sound blocking capabilities.

- Vibration Damping Materials: Specifically engineered to reduce structure-borne noise, vibration damping materials are crucial for mitigating noise that originates from mechanical vibrations. This category includes heavy-duty rubber mats placed under machinery, specialized damping compounds applied to vibrating surfaces, and isolation mounts designed to decouple vibrating components from the main structure. By absorbing and dissipating kinetic energy, these materials effectively prevent vibrations from spreading and converting into audible noise, thus controlling a common and persistent source of industrial sound.

The strategic choice of industrial soundproofing insulation fundamentally depends on whether your primary goal is to absorb, block, or dampen noise. In many complex industrial scenarios, a carefully considered combination of these various solutions will undoubtedly yield the most effective and sustainable noise control results.

Silence Is Golden: Investing in Industrial Soundproofing

Ultimately, finding and implementing the right soundproofing insulation for industrial use transcends simple noise reduction. It is a strategic investment in cultivating a safer, significantly more productive, and fully regulation-compliant working environment. The array of available options is vast, ranging from highly effective acoustic panels and dense mass-loaded vinyl to robust mineral wool and specialized vibration damping solutions. The most appropriate choice will always hinge on your specific noise challenges, budgetary considerations, and the unique insulation requirements of your facility.

Whether you choose to source materials from a trusted local supplier, explore the extensive offerings of online marketplaces, or engage with a professional, specialized soundproofing brand, the investment in high-quality industrial insulation will undoubtedly yield substantial long-term dividends. A well-soundproofed industrial space translates directly into fewer distractions for workers, a healthier and happier employee base, and smoother, more efficient operational workflows. So, if the relentless cacophony of industrial noise is transforming your workspace into an unwanted rock concert, it is unequivocally time to take decisive action and restore the invaluable calm that only effective soundproofing can provide.